Connecting device for inner and outer pipes of MQL (Minimal Quantity Lubrication) system

A technology of minimal lubrication and connecting devices, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to achieve good neutrality, good circulation, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

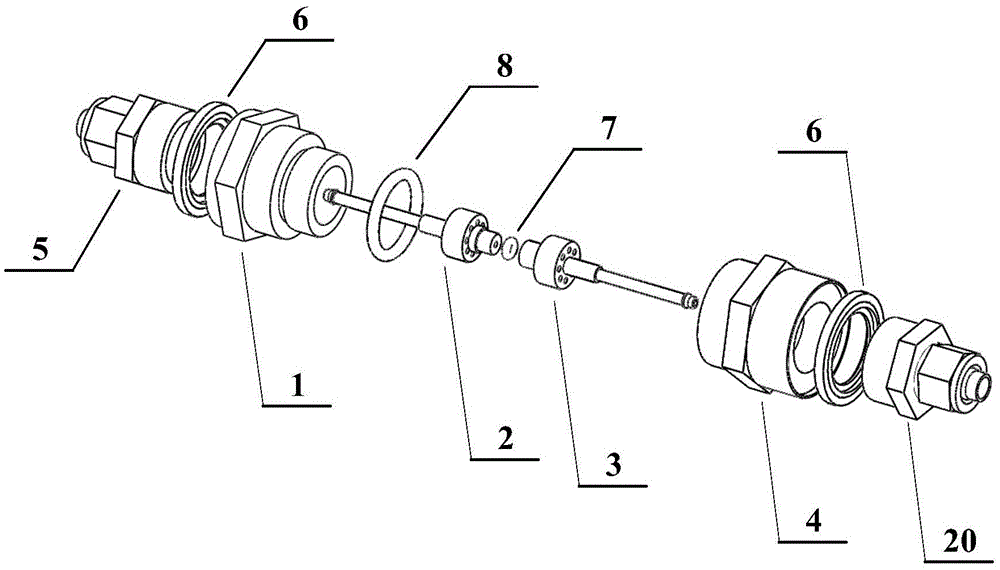

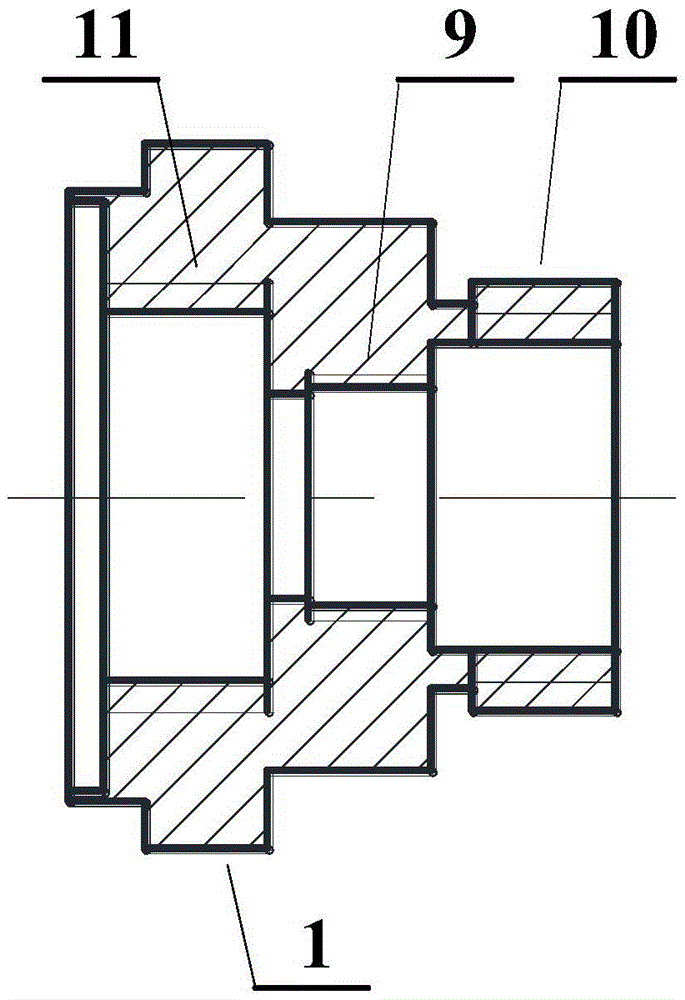

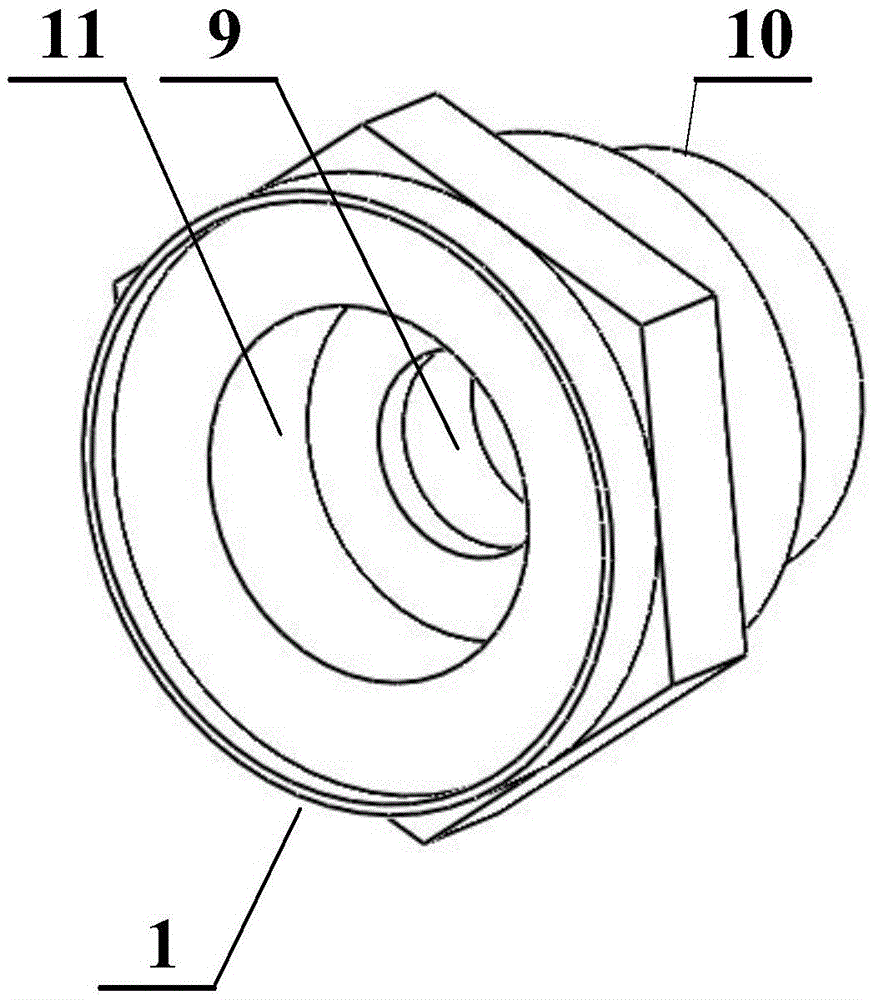

[0033] The invention provides a connection device for inner and outer pipes of a minimal quantity lubrication system, such as figure 1 with Image 6 As shown, the connecting device includes connecting shell A1, connecting shell B4, connecting inner core A2, connecting inner core B3, quick twist joint A5, quick twist joint B20, copper gasket 6, connecting inner core O-ring 7 and Connect the housing O-ring 8. The connection shell A1, the connection shell B4, the connection inner core A2, and the connection inner core B3 form a double-layer structure, and are divided into Image 6 The two parts A and B shown can be respectively connected with the two ends of the inner and outer pipes to be connected.

[0034]The connection shell A1 and the connection shell B4 are threadedly connected, and the O-ring 8 of the connection shell is used to realize sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com