A forming mechanism and forming method of a tubular parison plastic box

A molding mechanism and plastic box technology, which is applied to the molding of cylindrical parison plastic boxes and the field of forming mechanism of cylindrical parison plastic boxes, can solve the problems of prolonging the production cycle and affecting production efficiency, so as to prolong the production cycle and improve the production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

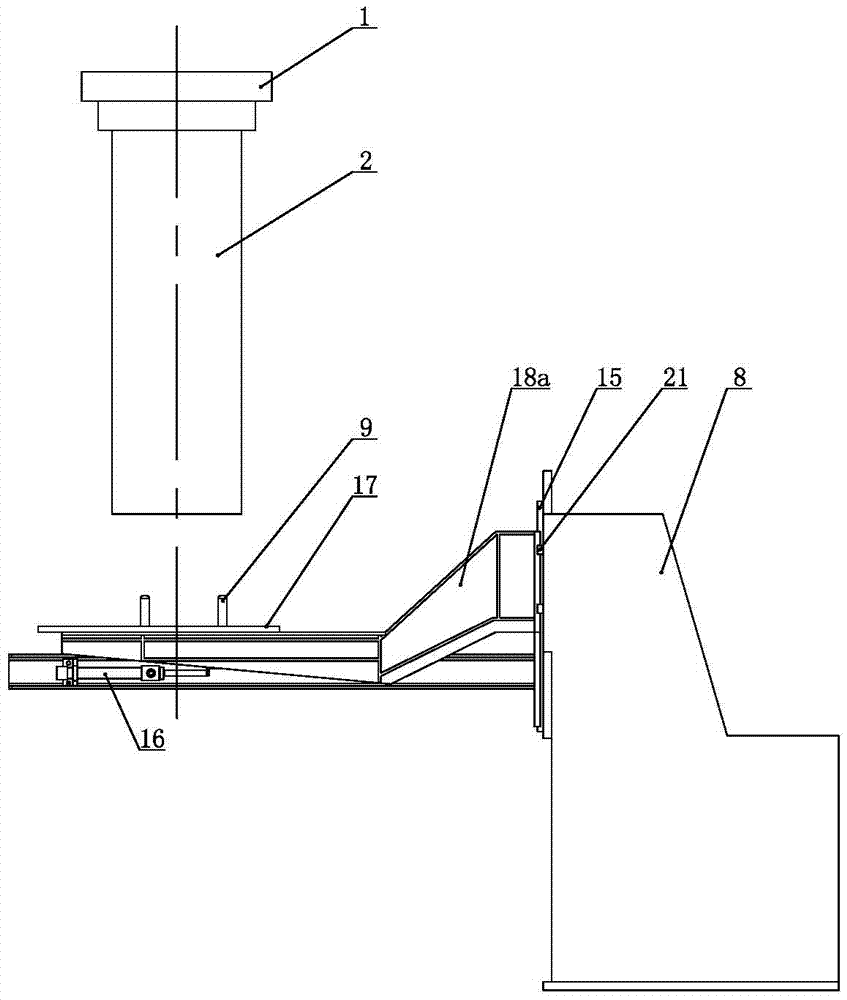

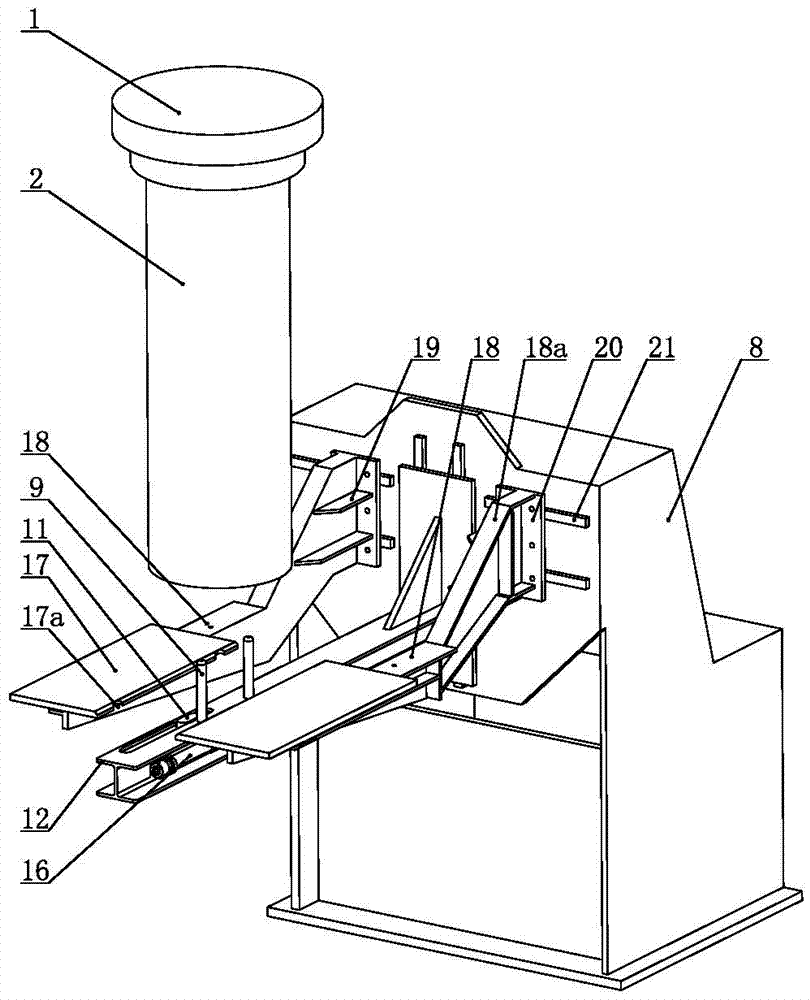

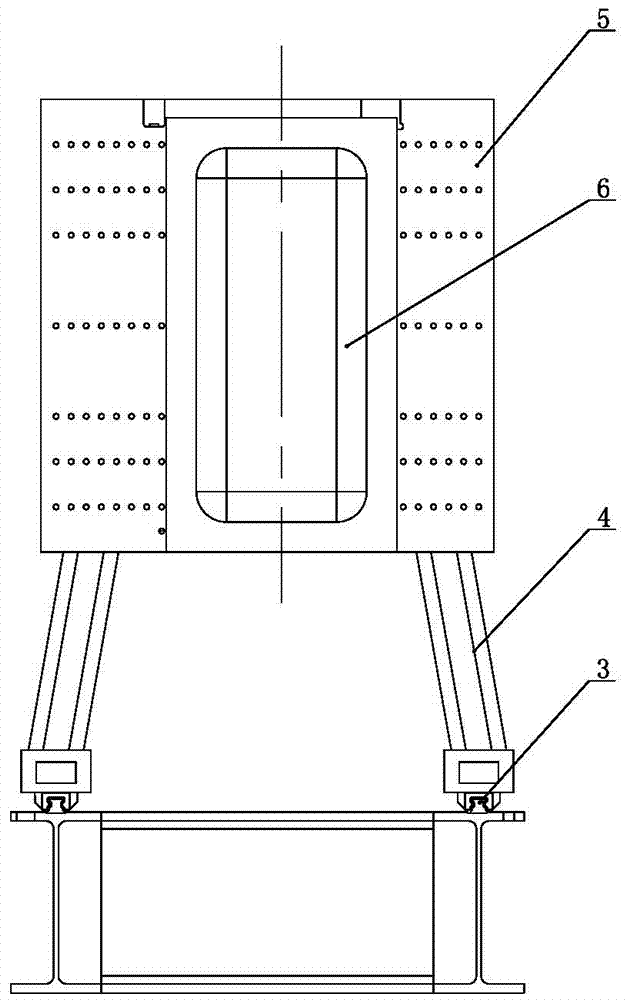

[0028] like Figure 1 to Figure 7 As shown, the forming mechanism of the tubular parison plastic box of the present invention comprises a tubular parison die head 1 that can extrude the tubular parison downwards, the center of the tubular parison die head 1 is provided with an air blowing device, and the barrel There is a Y guide rail on the ground below the shape parison die head 1, and a shuttle car that can move along the Y guide rail is provided on the Y guide rail. The X guide rail 3 is installed on the shuttle car. Or the left and right mold bases that move in opposite directions, the left mold base 4 and the upper part of the right mold base are respectively equipped with a left mold installation back plate 5 and a right mold installation back plate, and the left mold installation back plate 5 and the right mold installation back plate are opposite to each other. The left half-mold 6 and the right half-mold 7 are respectively installed on the end faces, and the mold clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com