A two-component fully drawn yarn spinning system

A spinning system and fully drawn yarn technology, which is applied in the field of bicomponent fully drawn yarn spinning system, can solve the problems of reducing operation difficulty and production cost, high production cost, difficult operation, etc., and achieves the reduction of operation difficulty and Production cost, production process shortening, and the effect of solving operational difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

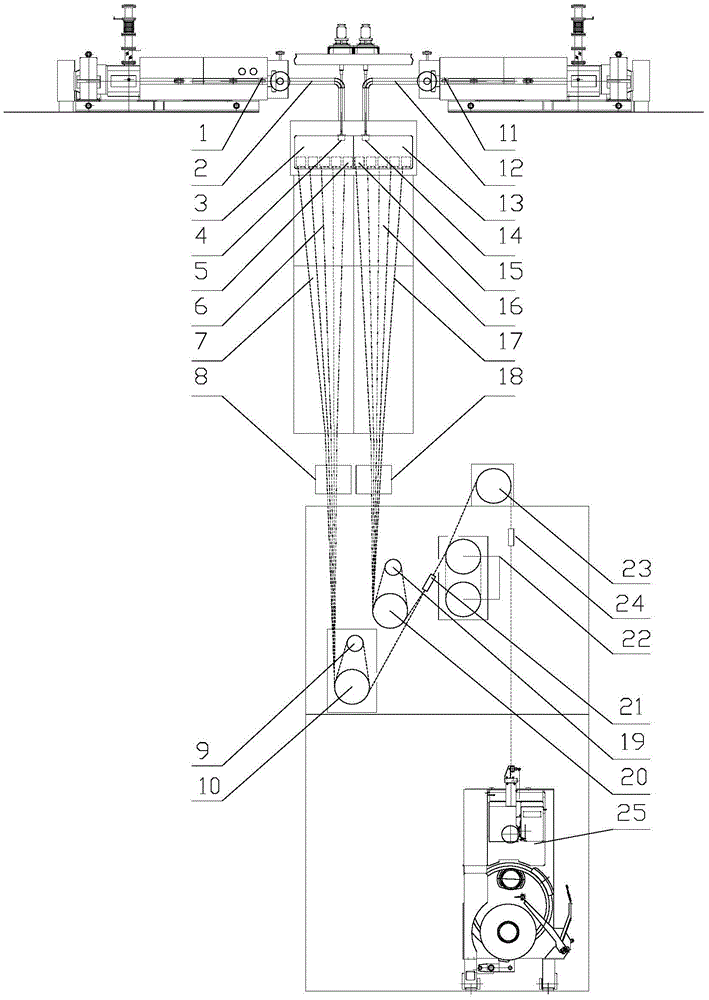

[0036] Please refer to figure 1 , the embodiment of the present application provides a two-component fully drawn yarn (abbreviated as FDY) spinning system, the spinning system includes: two sets of spinning mechanisms, two tankers arranged side by side (including A tanker 8, B tanker 18 ), two first heat roller drawing mechanisms arranged side by side, a first network 21, a second heat roller drawing mechanism (including two second heat rollers 22) and a godet 23. In addition, the spinning system may also include a second network 24, a winder 25 and a frame. The connection relationship of each component in the spinning system will be described separately below.

[0037] Each of the two sets of spinning mechanisms includes a screw extruder, a spinning box, a blower and a tunnel, wherein the same components in the two sets of spinning mechanisms are arranged side by side. Specifically, the two groups of spinning mechanisms are denoted by A and B respectively, and the two group...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap