Basement backfill area reinforcing method

A basement and regional technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as surface layer sinking and lack of settlement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

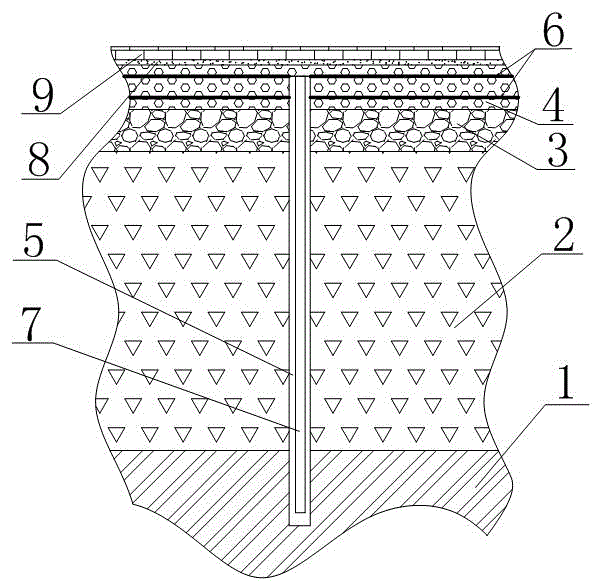

[0020] Such as figure 1 As shown, a method for reinforcing a basement backfill area of the present invention comprises a base soil layer 1, a backfill soil layer 2 is laid on the base soil layer 1, a mattress layer 3 is laid on the backfill soil layer 2, and the mattress layer 3 Consisting of graded sand and gravel, the maximum particle size is less than 3.0cm, the mud content is less than 5%, and its thickness is 15cm to 25cm. On the cushion layer 3, a reinforced concrete slab 4 is arranged. The thickness of the reinforced concrete slab 4 is Generally not less than 30cm, there are two layers of steel mesh 6 in the reinforced concrete slab 4, the diameter of the steel bar is not less than Ф14, the filling material is C25 concrete, and grouting is provided in the part extending downward from the reinforced concrete slab 4 to the base soil layer 1 Column 5, grouting column 5 is cylindrical, and grouting steel pipe 7 is installed inside it, after drilling to at least 2 meters b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com