Dry type filtration dust removal system for roadway driving working face

A technology for excavating working face, filtering and dust removal, applied in the directions of dispersed particle filtration, dust prevention, mine/tunnel ventilation, etc., it can solve the problems of crowded space, severe pneumoconiosis, difficult to adapt to the space of the excavation working face, etc., and achieves low operating resistance. , The effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

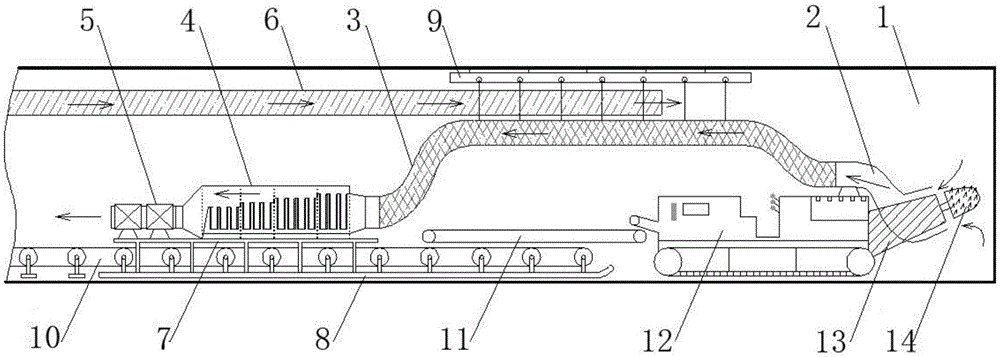

[0015] Below in conjunction with the accompanying drawings the present invention will be further described, the left and right directions in the following description and figure 1 The left and right directions in are the same.

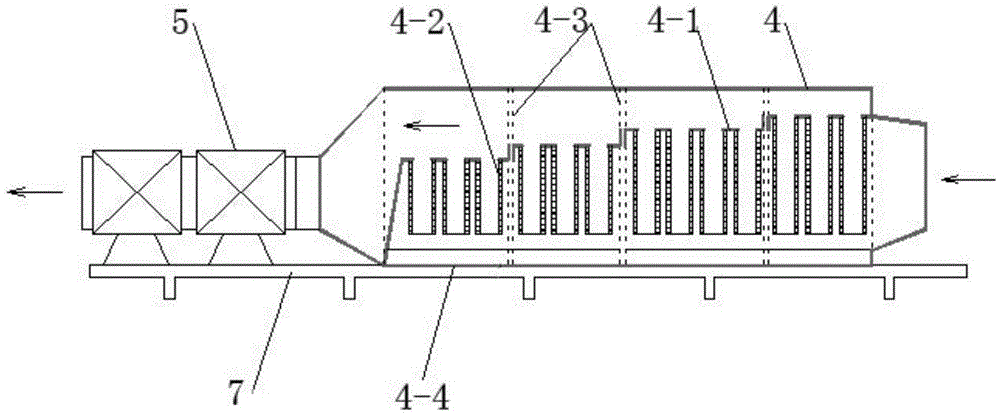

[0016] like figure 1 and figure 2 The shown dry filter and dust removal system for roadway excavation working face includes positive pressure air cylinder 6, roadheader 12, belt conveyor 10 and loader 11, and the tail of the roadheader 12 is fixed to the loader 11 Connection; the reloading machine 11 is slidably installed above the tail of the belt conveyor 10, the tail of the belt conveyor 10 is installed on the mobile frame 8, and the air outlet of the positive pressure air cylinder 6 faces the excavation working face, and also includes dust suction Cover 2, negative pressure air cylinder 3, dry filter dust collector 4, withdrawable fan 5, support 7, support 7 is nested above the belt conveyor 10 and installed on the mobile frame 8; withdrawable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com