Electromagnet structure

A technology of electromagnet and blocking structure, which is applied in the direction of electromagnet with armature, electromagnet, circuit, etc. It can solve the problems of increasing power consumption, increasing the coil, and difficulty in meeting the demand, and achieve the effect of avoiding bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

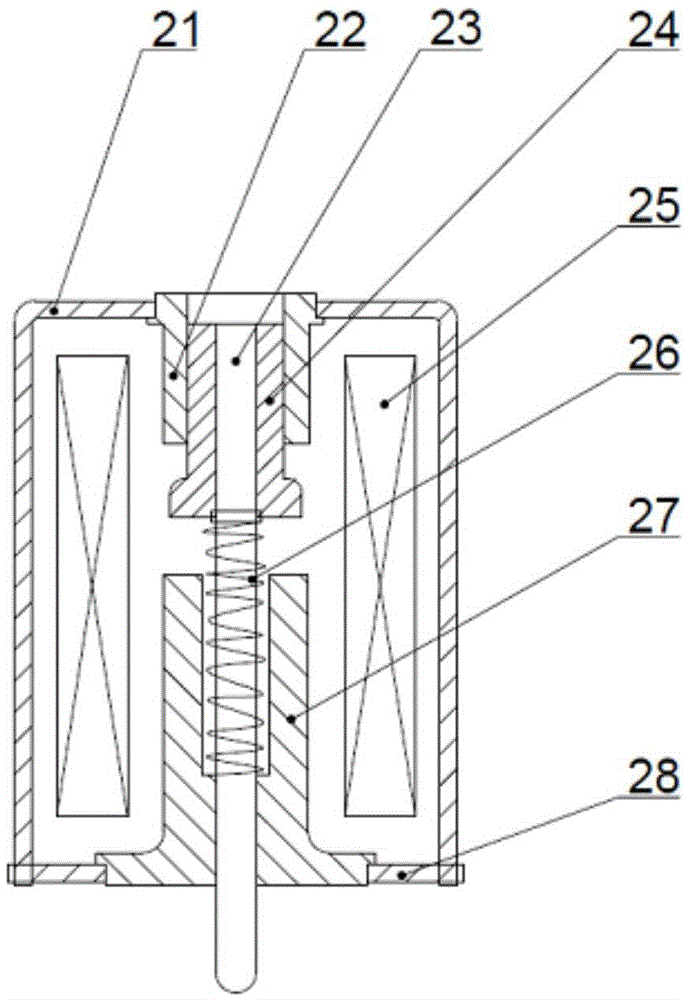

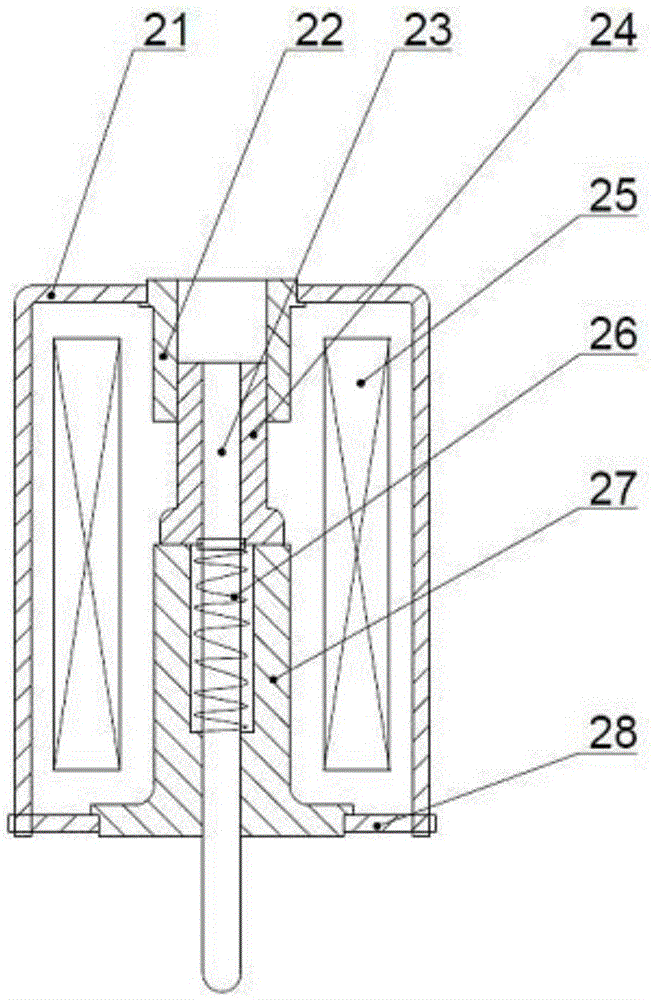

Embodiment 1

[0050] This embodiment provides an electromagnet structure, which does not include a push rod structure. For specific structures, refer to image 3 shown, including:

[0051] Magnetic pole 1, capable of moving under the action of a magnetic field;

[0052] The mounting part 3 is installed in cooperation with the magnetic pole 1, used to guide the movement of the magnetic pole 1, and has a first blocking structure 31 opposite to the magnetic pole 1;

[0053] The first elastic member 41 is installed between the magnetic pole 1 and the first blocking structure 31;

[0054] The first coil 51 is arranged around the mounting part 3 and is close to the first blocking structure 31 for generating a magnetic field when electrified to attract the magnetic pole 1 close to the first blocking structure 31 to compress the first blocking structure 31 An elastic member 41 stores energy;

[0055] The second coil 52 is arranged around the mounting part 3 and away from the first blocking struc...

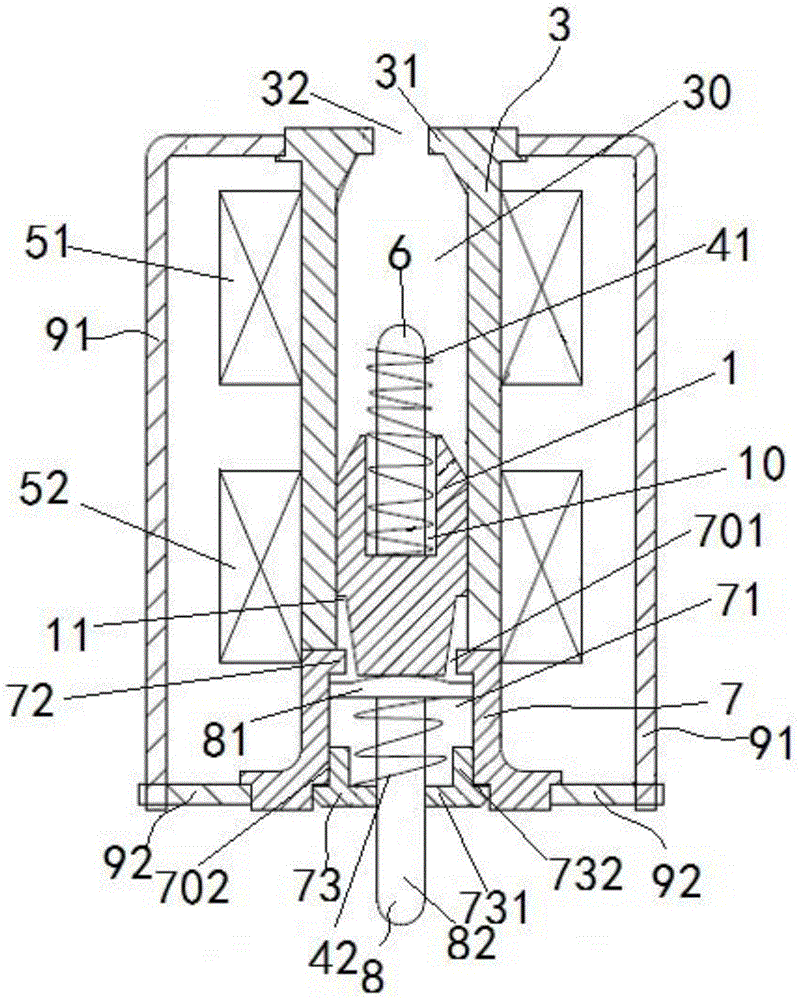

Embodiment 2

[0069] This implementation provides an electromagnet structure, such as image 3 As shown, while including the structure described in Embodiment 1, a mandrel structure is also included.

[0070] Wherein the ejector rod structure includes: a base 7, which is arranged opposite to the end of the mounting part 3 away from the first blocking structure 31, has an installation space 71, communicates with the installation space 71, and allows the insertion of the magnetic pole 1 a first opening 701, and a second opening 702 opposite to the first opening 701;

[0071] The push rod 8 has a blocking portion 81 located inside the installation space 71 , and a main body portion 82 connected to the blocking portion 81 and capable of protruding from the second opening 702 ;

[0072] The second blocking structure 72 is disposed on the inner wall of the first opening 701 and used to block each other with the blocking portion 81 ;

[0073] The third blocking structure 73 is disposed on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com