Vehicle power unit

A power unit and vehicle technology, which is applied to vehicle parts, vehicle gearboxes, bicycles, etc., can solve the problems of power unit expansion, achieve the effect of improving the degree of freedom, realizing miniaturization, and avoiding expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

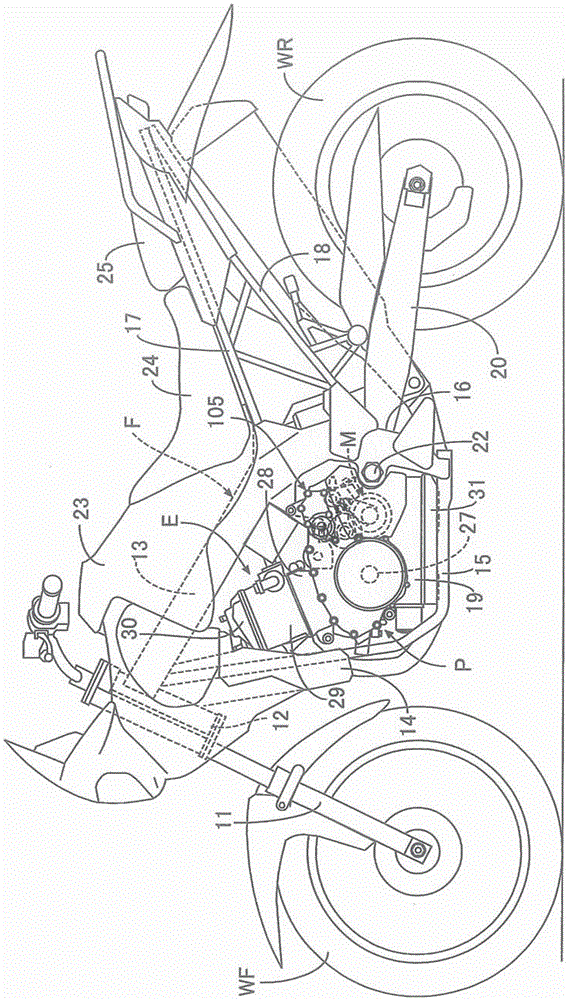

[0079] First, in figure 1 Among them, the frame F of a motorcycle that is a straddle-type vehicle includes: a head pipe 12 that supports a front fork 11 that pivotally supports a front wheel WF so as to be steerable; A pair of left and right main frames 13; a pair of left and right descending frames 14 extending backward and downward with a sharper inclination than the above-mentioned main frame 13; a lower frame 15 extending backward from the lower ends of the two descending frames 14; The rear end of the main frame 13 extends downward and a pair of left and right central frames 16 connected to the rear ends of the two lower frames 15; a seat rail 17 ; and a pair of left and right rear subframes 18 connecting the lower portion of the center frame 16 and the rear portion of the seat rail 17 .

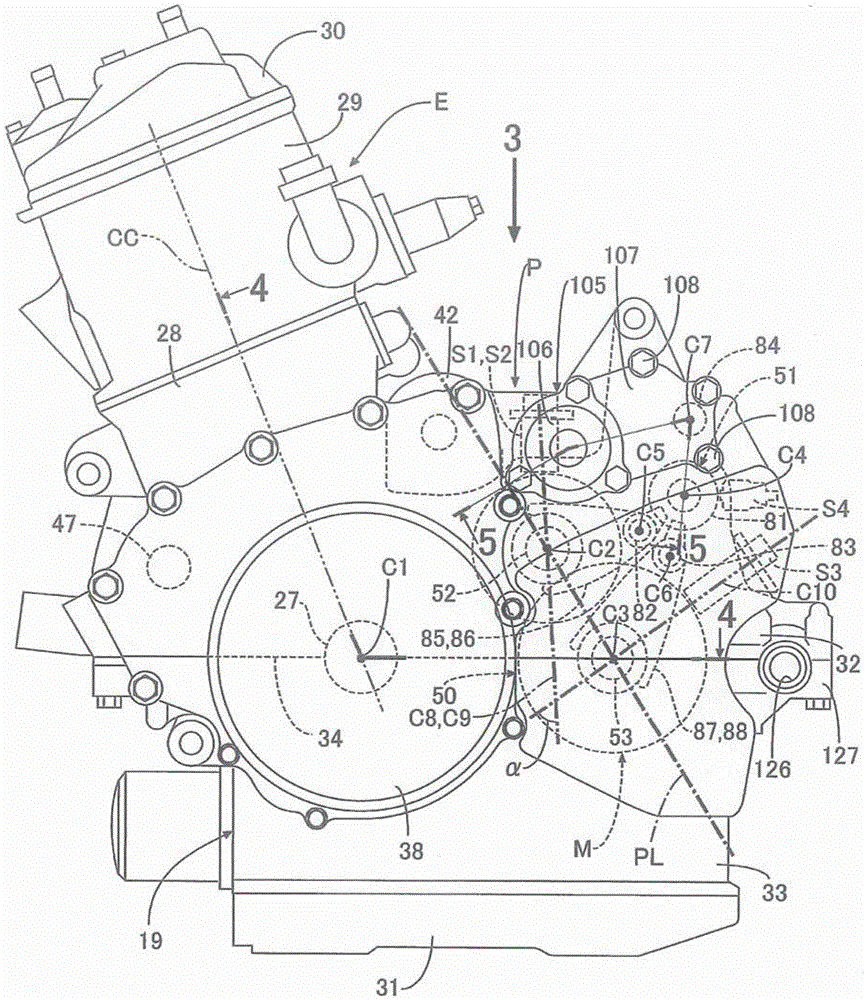

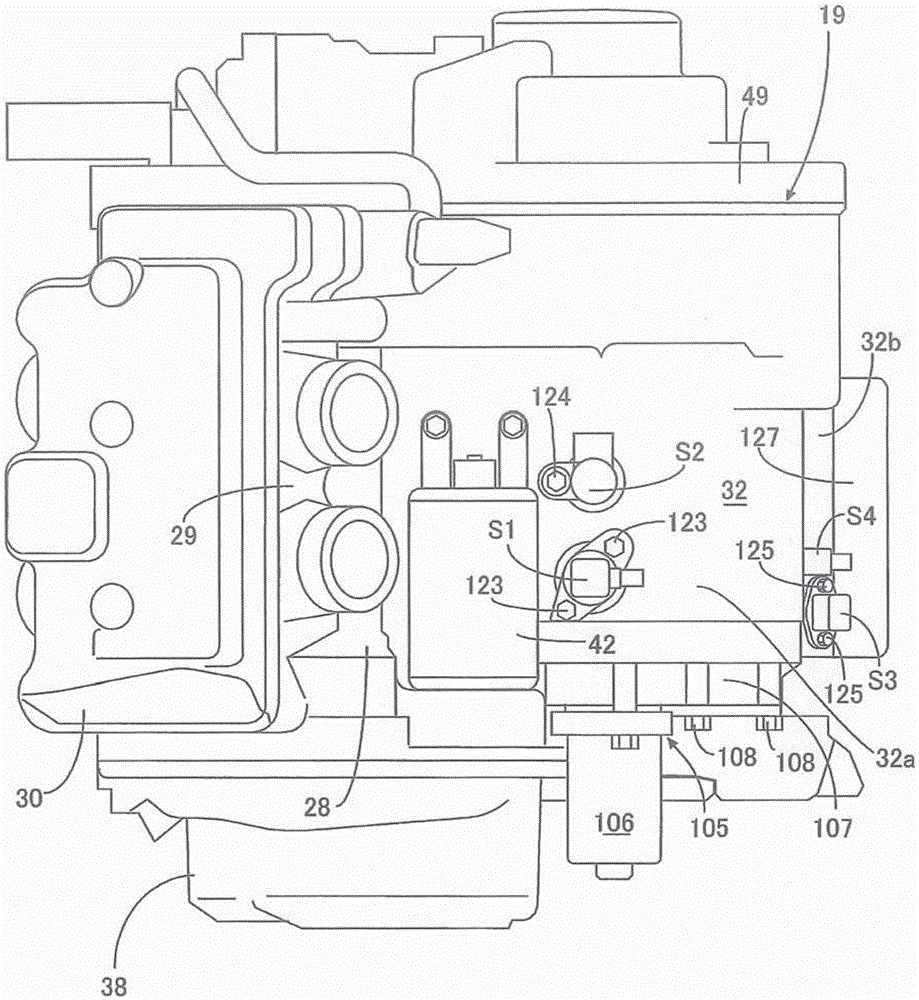

[0080] In the area surrounded by the main frame 13, the down frame 14, the lower frame 15, and the center frame 16, a two-cylinder internal combustion engine E and a transmission M (re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com