Rice huller and rice husking machine

A technology for a husker and a rice mill, which is applied in the field of rice mills, can solve the problems of loss of nutrients in rice grains, dull rice surface, heavy motor load, etc., and achieves the effects of protecting nutrients, being easy to accept and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

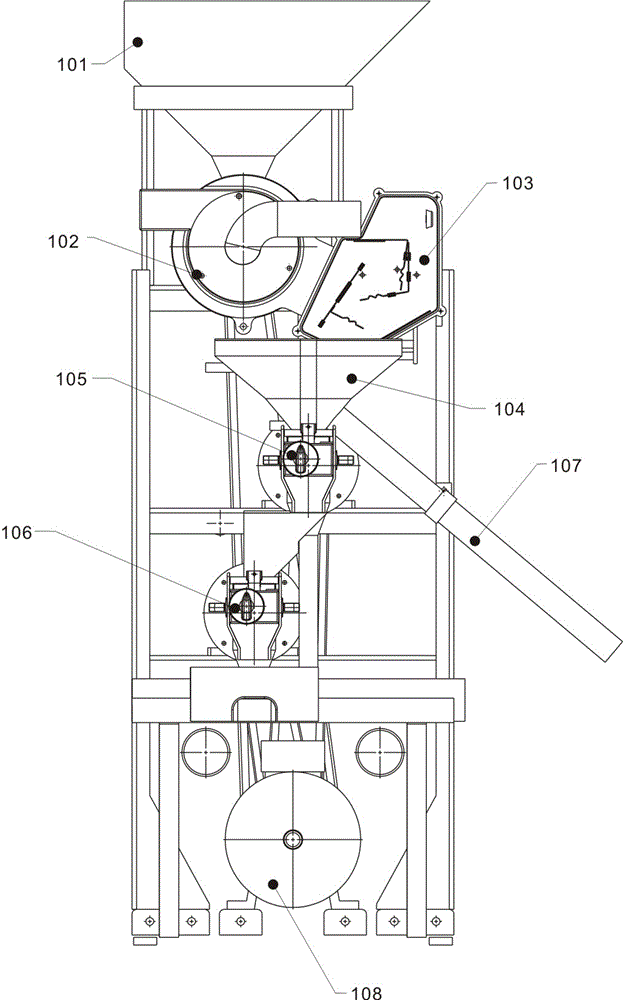

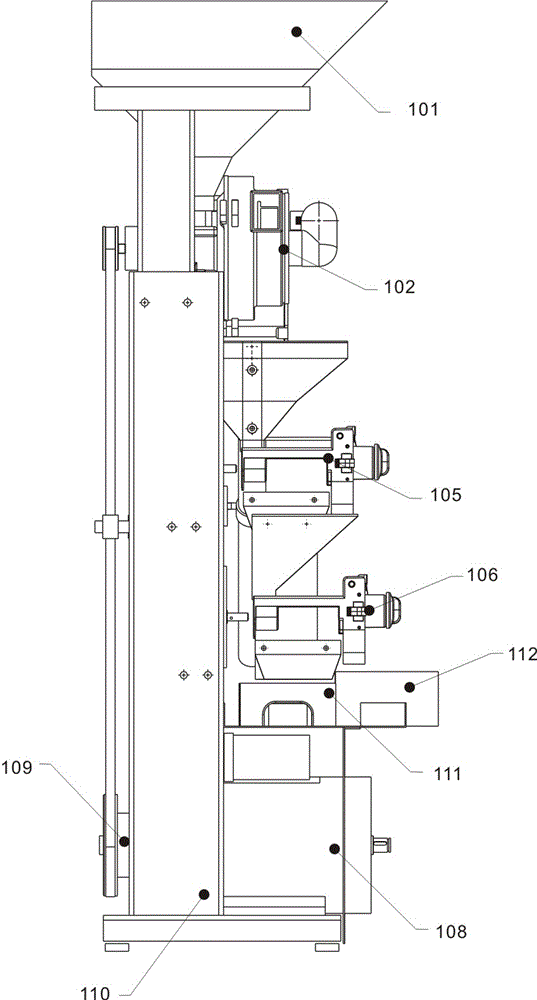

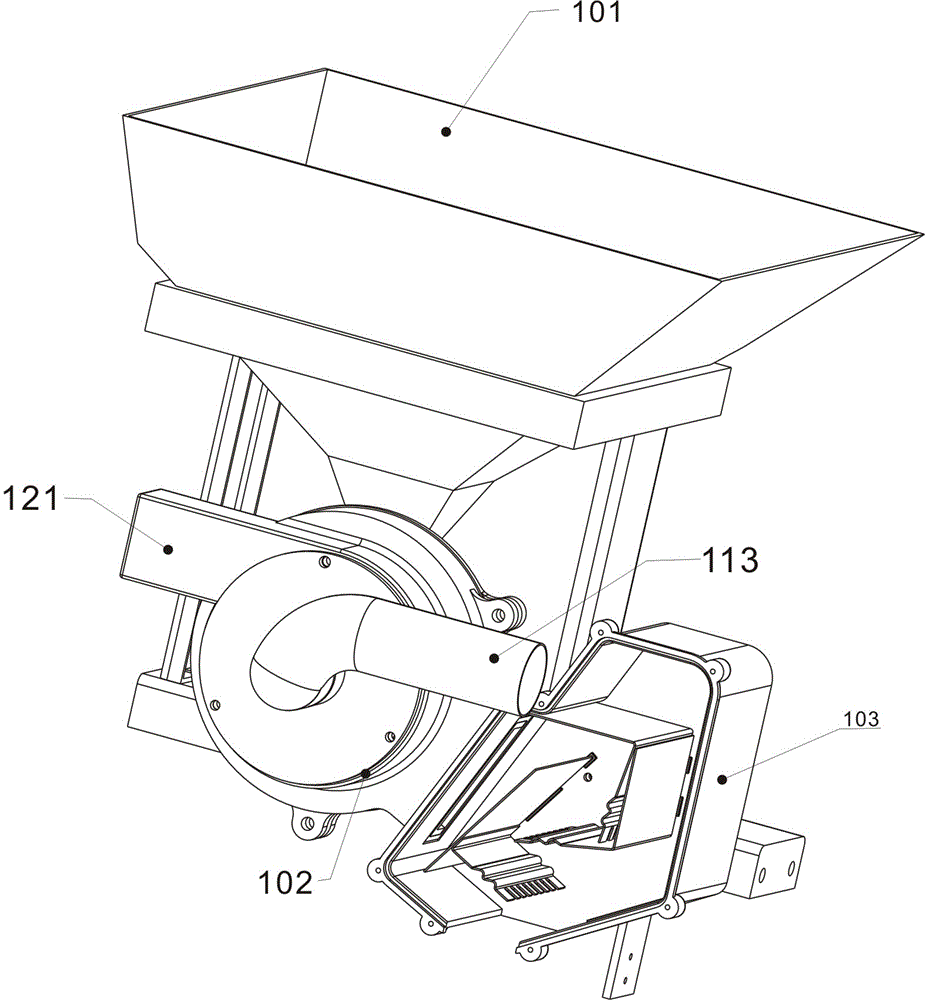

[0035] The following will be combined with Figure 1-9 The present invention is described in detail, and the technical solutions in the embodiments of the present invention are clearly and completely described. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0036]The present invention provides a kind of huller 102 through improvement, as Figure 5-9 Shown, comprise driven pulley 120, frame 123, shell 126, end cover 125, central shaft 127, dividing plate 128, rubber surface 118, suction chaff wheel 116 and grain throwing wheel 117; Copeland wheels 117 are installed on the central shaft 127 respectively, separated by a partition 128 and a shell 126; the end of the shell 126 is equipped with an end cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com