Curing device for painting line

A coating production line and curing device technology, which is applied in the direction of the device for coating liquid on the surface, the coating, the pre-treated surface, etc., to achieve the effect of uniform spray paint surface, good curing effect, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

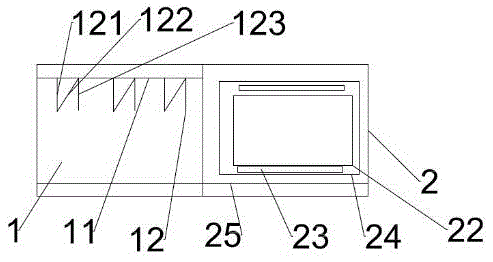

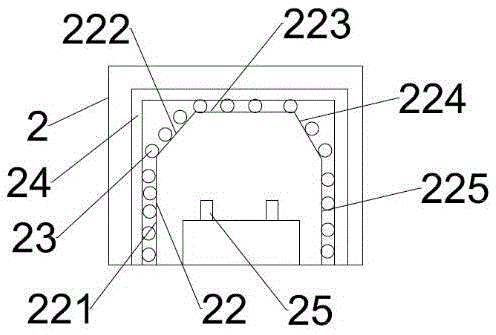

[0017] Attached below Figure 1-2 And examples, the specific implementation mode of the present invention is described further. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0018] The technical scheme of concrete implementation of the present invention is:

[0019] A curing device for a coating production line, comprising a first drying room 1, a second drying room 2 and a support rail 25, the first drying room 1 is connected to the second drying room 2, and the support guide rail 25 passes through The above-mentioned first drying room 1 and the second drying room 2, the above-mentioned support guide rail 25 is rollingly equipped with a support plate, the support plate is used to place the workpiece to be dried, the above-mentioned support plate is connected with a traction mechanism, and the above-mentioned first drying Room 1 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com