Metal 3D (three-dimensional) printing device and metal 3D printing method

A 3D printing and metal technology, applied in the direction of additive processing, etc., to achieve the effect of eliminating production costs, simple equipment, and simple testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

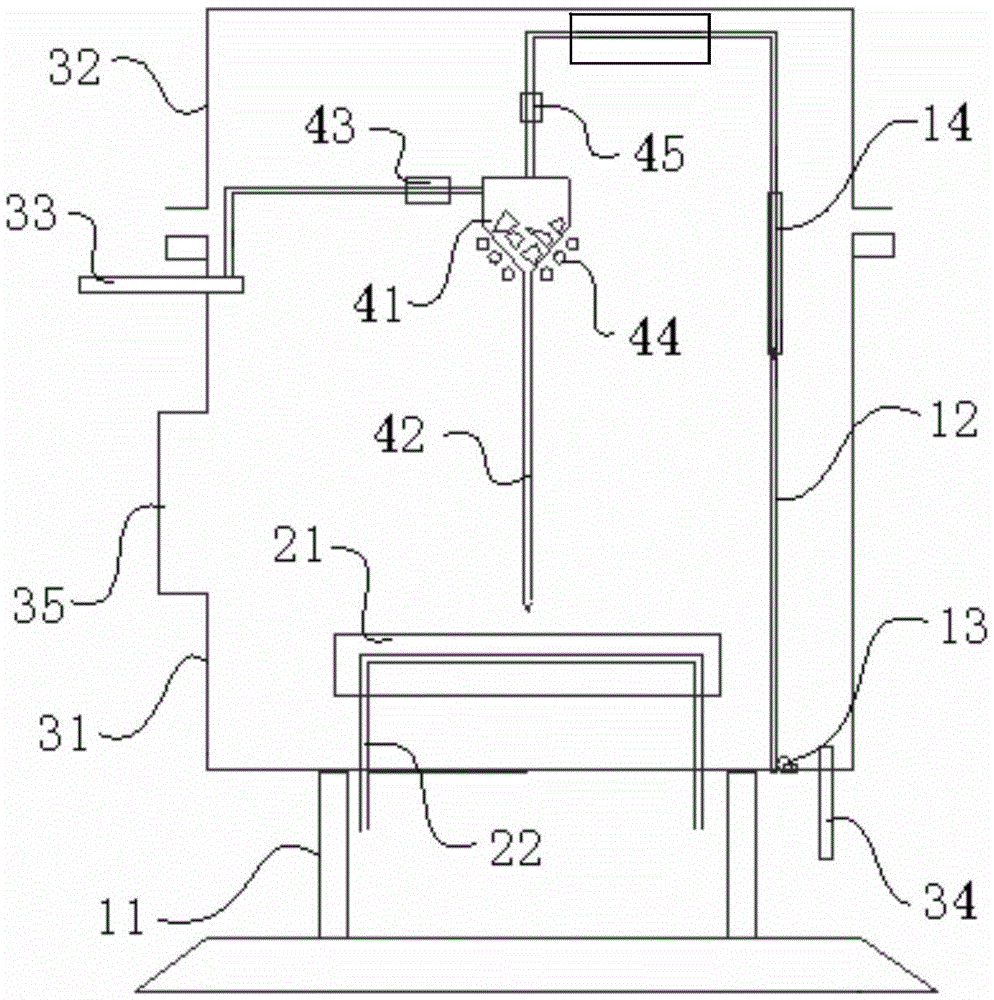

[0042] see figure 1 , the new metal 3D printing device in the illustration includes four parts: rack system, heating printing system, cooling molding system, and atmosphere control system, including workbench 11, moving bracket 12, plane moving assembly 13 and vertical moving assembly 14, Among them, the workbench is used to support the other three systems, and the moving bracket 12, the planar moving assembly 13 and the vertical moving assembly 14 are used to set and move the heating and printing system to move, which can realize the movement of the heating and printing system at any position in space, wherein, The mobile bracket 12 is made of austenitic 304 stainless steel frame, and the vertical moving component 14 adopts a vertical hydraulic telescopic rod with a diameter of 25mm. In the horizontal plane, a screw mechanism combined with a motor can be used to drive or a linear motor can be used to drive along the horizontal X and Y directions; The rack system in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com