Concrete batching automatic ration distribution method

A concrete and automatic technology, which is applied in chemical instruments and methods, mixing operation control, clay preparation devices, etc., can solve the problems that the batching cannot be automatically controlled, the labor volume of workers is large, and the batching efficiency is discounted, so as to save manpower and material resources, reduce Labor intensity, the effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

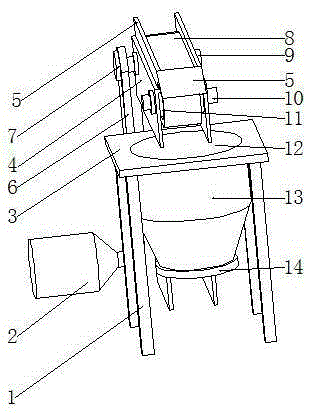

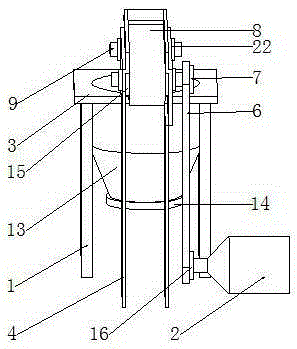

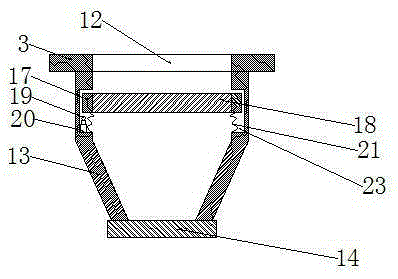

[0025] As shown in the accompanying drawings, a kind of concrete batching automatic quantitative distribution method of this patent realizes the metering of concrete batching by setting a spring 21 and a weighing device 17 inside the housing 13 of the concrete batching device; Install the lifting device 20 with a travel switch 19 on the lower part, adjust the distance between the travel switch 19 and the weighing device 17 through the lifting device 20, and use the travel switch 19 to control the power on and off of the feeding motor 2 to realize automatic filling of concrete ingredients with abort.

[0026] The specific working process is:

[0027] Step 1. Control the lifting device 20 to adjust the distance between the travel switch 19 and the weighing device 17 according to the demand for concrete batching;

[0028] Step 2, start the concrete batching device, then the feeding motor 2 works, and the feeding motor 2 drives the automatic feeding device to transfer the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com