Heavy truck lifting air suspension system

An air suspension and suspension system technology, which is applied in the field of heavy truck lifting air suspension system, can solve the problems of inconvenient layout and installation, too many parts, and unfavorable weight reduction of the whole vehicle, and achieves a simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

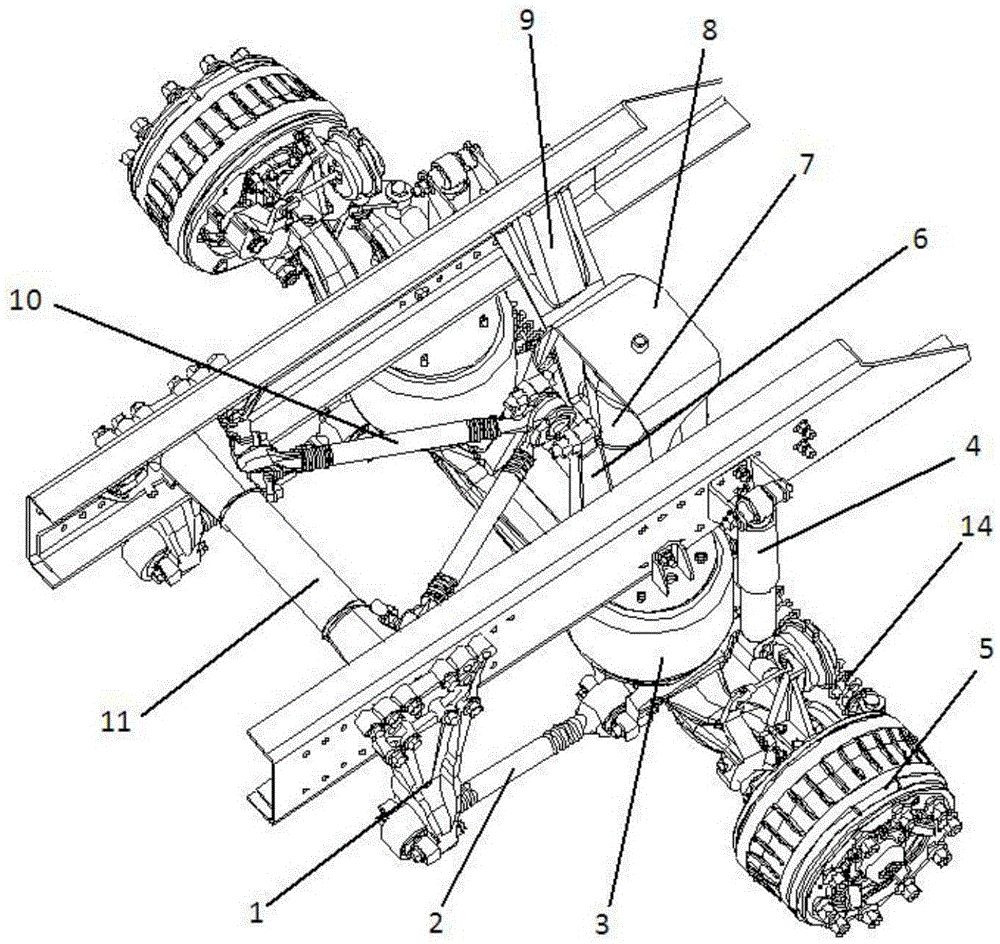

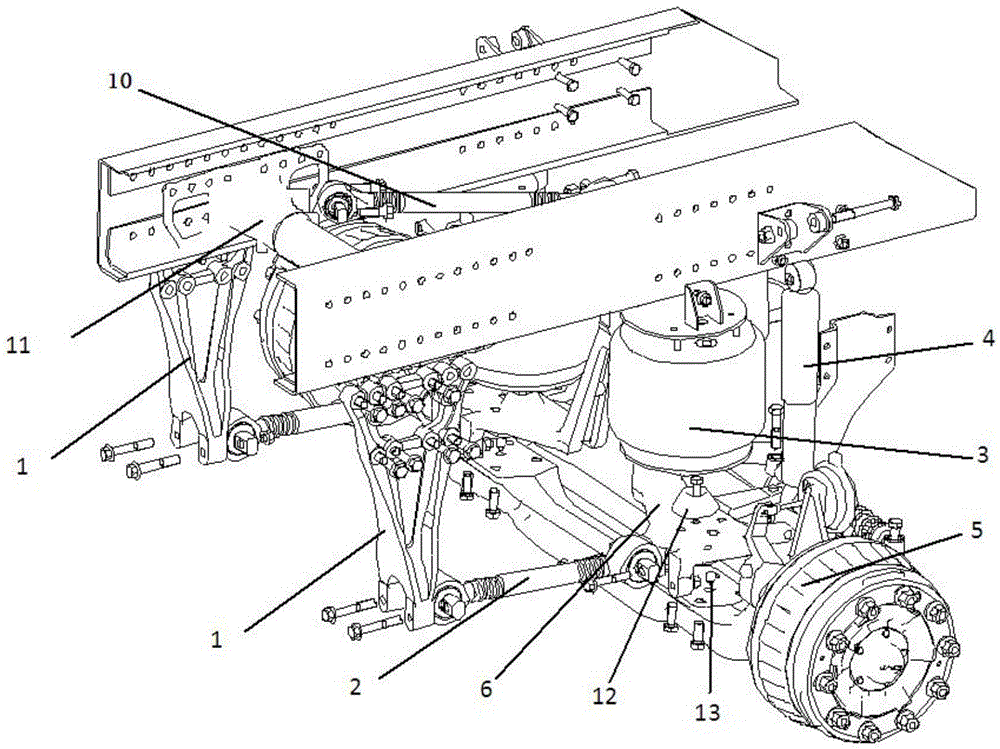

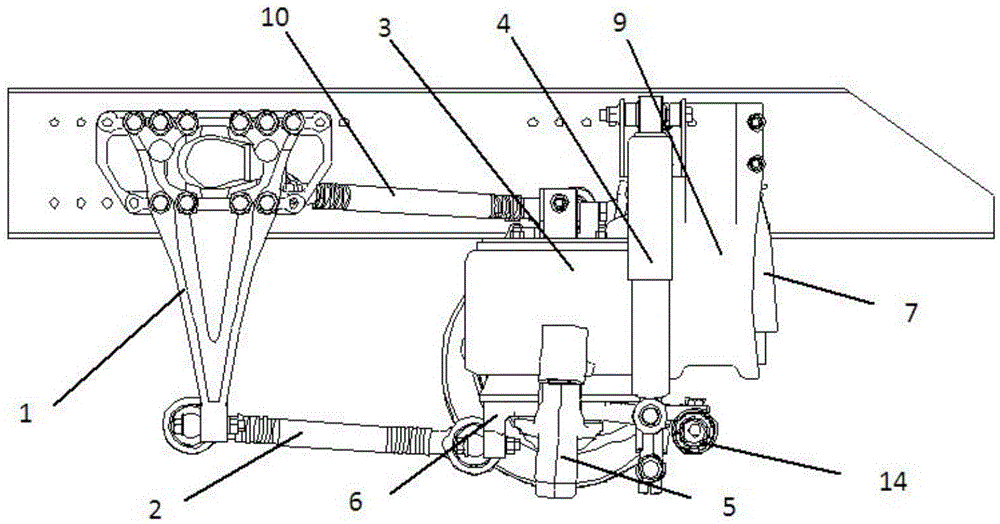

[0031] Such as Figure 1-Figure 12 As shown, a heavy truck lifting air suspension system provided by the present invention is installed between the I-beam and the lifting bridge 5, including a shock absorber, a thrust rod, and a positioning bracket fixed on the lifting bridge 5 6. The positioning bracket is installed on the lifting bridge 5 through the bracket mounting holes 62 on both sides. The positioning bracket 6 is in the shape of a few characters, including horizontal mounting plates 68 on both sides and a raised mounting frame 66 in the middle;

[0032] The bearing air springs 3 are respectively fixed on the two mounting plates 68, the top of the bearing air springs 3 is in contact with the bottom surface of the vehicle frame longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com