Electronic control separate type active anti-roll bar and anti-side-roll method

A separate, anti-roll bar technology, used in interconnection systems, suspension, transportation and packaging, etc., can solve the problems of high processing cost, poor commonality of parts, and complex structure of active stabilizer bars, achieving low cost, The effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

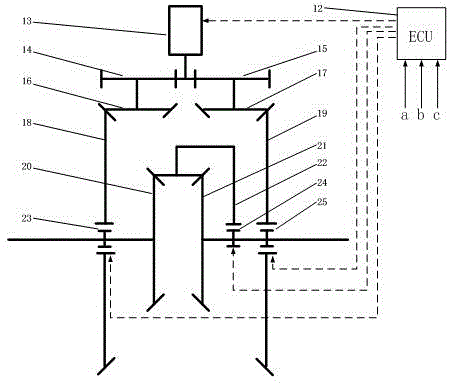

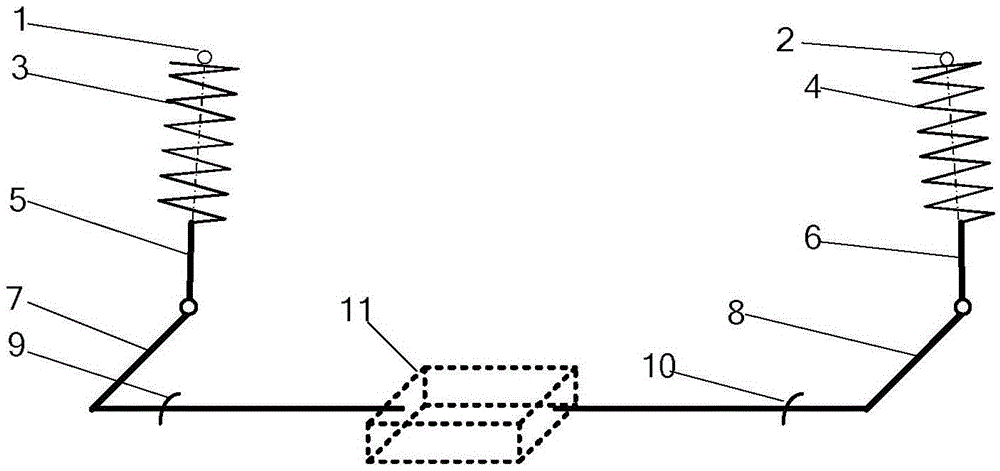

[0044] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0045] Such as figure 1 with figure 2 As shown, the present invention discloses an electronically controlled separate active anti-roll bar, including a left torsion bar 7, a right torsion bar 8, a left support arm 5, a right support arm 6, an active control module 11, a steering wheel angle sensor, and a left suspension Frame displacement sensor 1 and right suspension displacement sensor 2;

[0046] The left torsion bar 7 and the right torsion bar 8 are both L-shaped, and one of the sides is fixed to the frame of the automobile through a bushing;

[0047] The end of the other side of the left torsion bar 7 is hinged to one end of the left support arm 5, and the end of the other side of the right torsion bar 8 is hinged to one end of the right support arm 6;

[0048] The other ends of the left support arm 5 and the right support arm 6 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com