Miniature mechanical sliding rail type controllable flapping rotor craft

A micro-mechanical, slide rail-type technology, applied in the field of aircraft, can solve problems such as flutter, achieve the effect of stable flight, overcome the horizontal shaking of the body, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

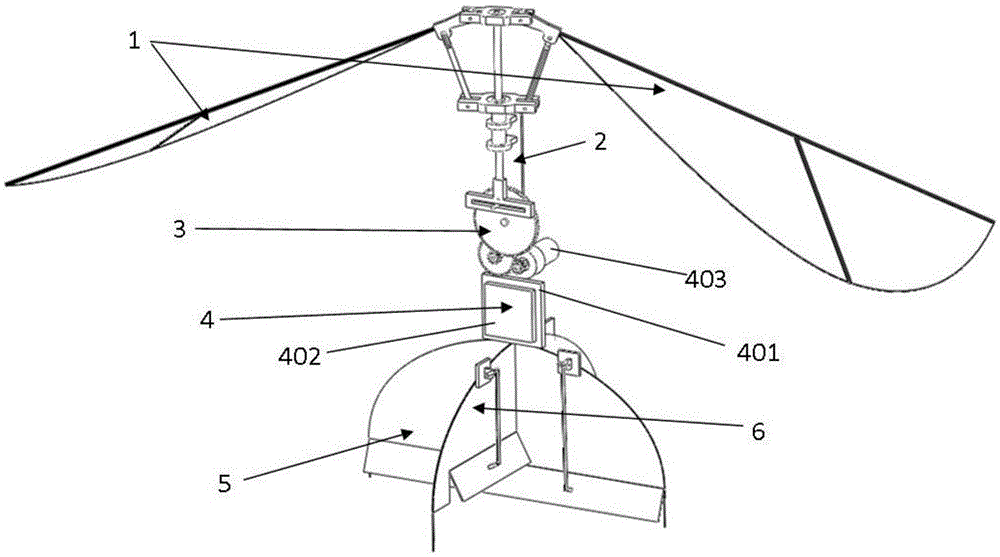

[0035] A kind of micro-mechanical slide rail type flapping rotor aircraft of the present invention, as figure 1 As shown, it includes a wing 1, a fuselage 2, a transmission mechanism 3, a power unit 4, a forward flight control device 5, and a steering control device 6.

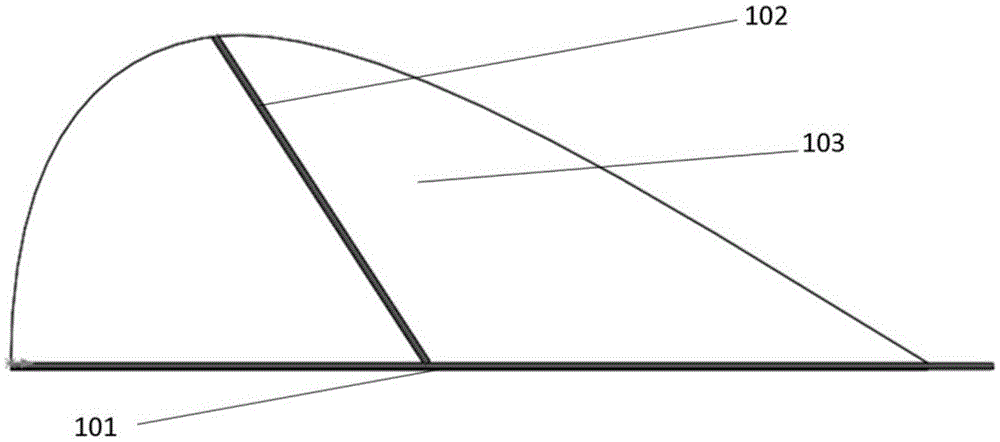

[0036] Wing 1 as figure 2 As shown, it includes a wing main spar 101 , a wing auxiliary spar 102 , and a film 103 . The root of the wing main beam 101 is fixed to the wing mounting frame 307 of the transmission mechanism 3; the wing auxiliary beam 102 is glued to the wing main beam 101 at a certain angle; and above the wing spar 102.

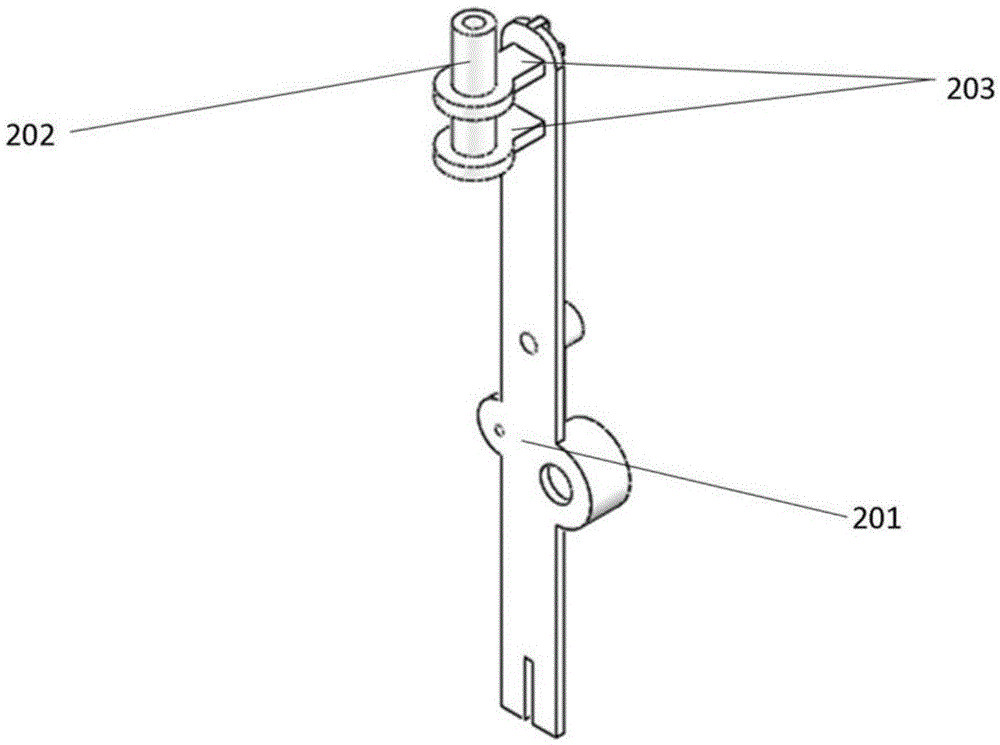

[0037] fuselage 2 as image 3 As shown, it includes a plate structure 201 capable of fixing motors and gears, a sleeve 202 , and two sleeve supports 203 . The sleeve 202 is fixedly connected to the plate structure 201 through two support members 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com