Multifunctional wire barrow

A pay-off car and multi-functional technology, applied in the field of electric power construction tools, can solve the problems of unreasonable structure of the pay-off car, low construction efficiency, easy knotting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

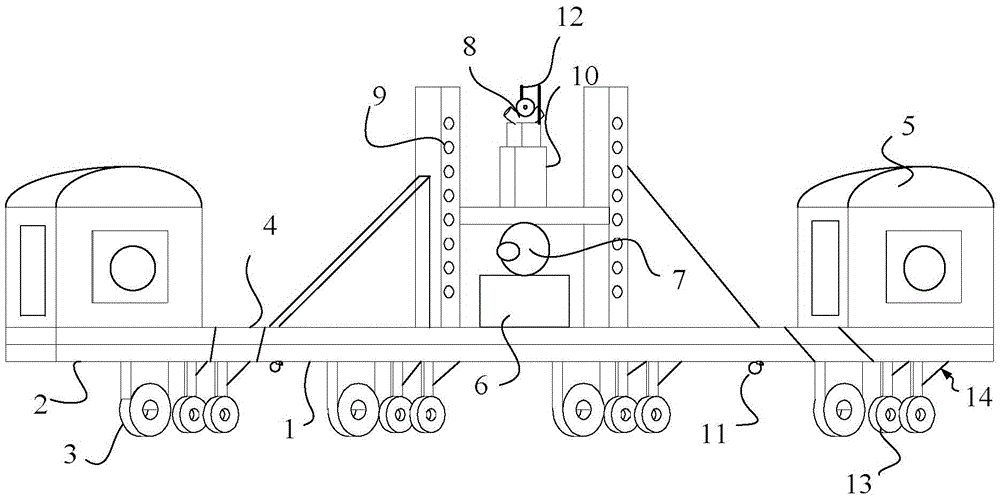

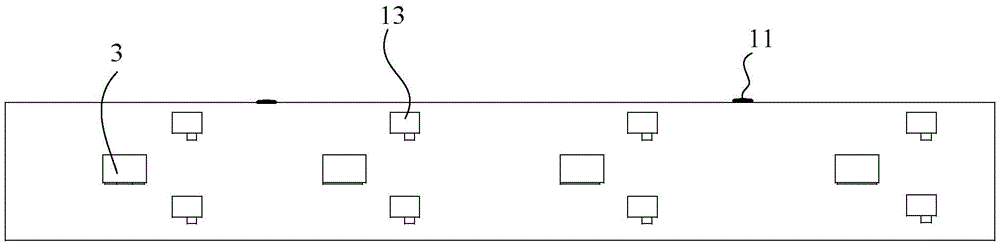

[0017] Example 1, such as figure 1 In the shown embodiment, a multifunctional pay-off vehicle is provided, including a vehicle body 1, a tractor head 2 and wheels 3. The entire vehicle body is in the shape of a long, narrow and flat rectangular parallelepiped, and the tractor head 2 provides the forward power and control of the pay-off vehicle. Parts in the forward direction of the entire body. There are two tractor heads 2 in this embodiment, and the two tractor heads 2 are respectively located at the front and rear ends of the vehicle body, and the two tractor heads 2 are equipped with tractors 41, 42 and cabs 51, 52 respectively. During the process of the pay-off work of the pay-off vehicle, the operator controls the tractor 41 in the cab 51 to pull the vehicle body forward. After completing the wiring work, the operator can go to the cab 52 at the other end of the vehicle body to control the A tractor pulls 42 to move the vehicle body in the opposite direction to carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com