Artificial wetland substrate integral filling and laying method

A technology of artificial wetlands and laying methods, which is applied in the direction of chemical instruments and methods, biological treatment devices, water/sludge/sewage treatment, etc. The time for processing efficiency, the construction period is short, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

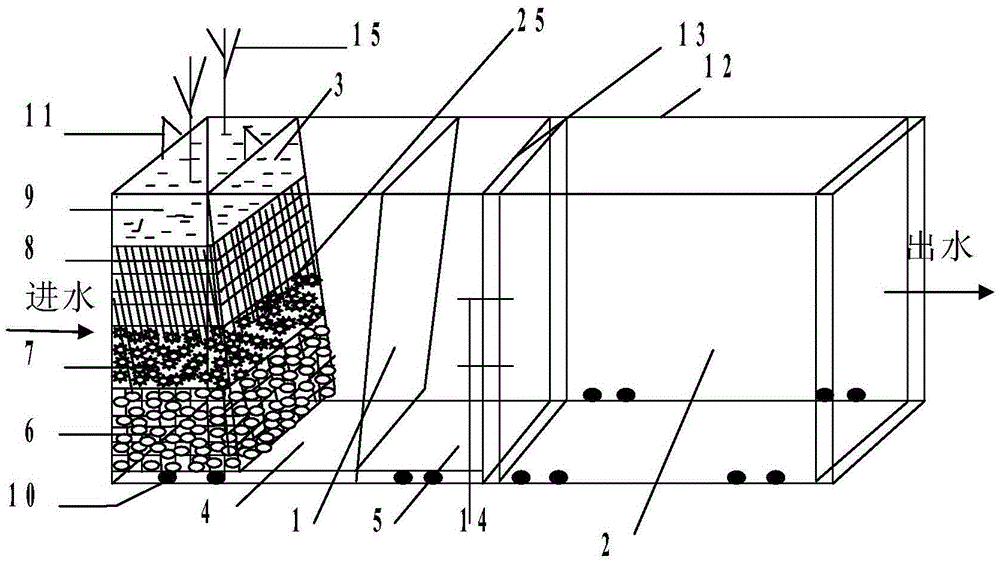

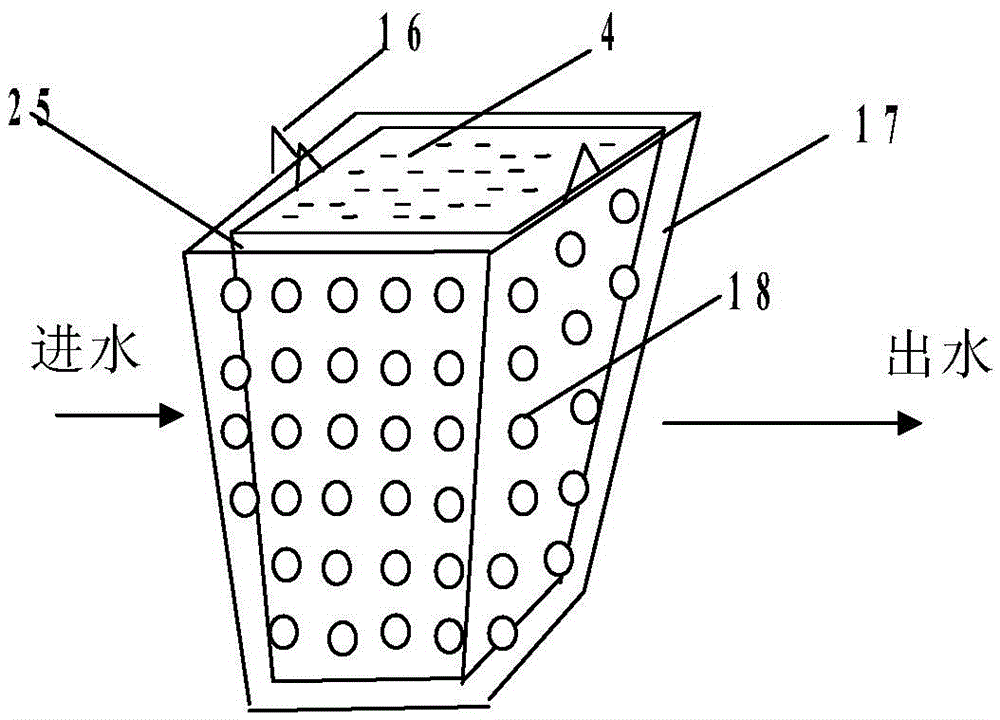

[0024] An integrated filling and laying method of constructed wetland matrix. The constructed wetland is composed of several relatively independent and movable modules in series, parallel or series-parallel combination, which can be quickly combined horizontally or vertically at the construction site according to the processing needs. connection to solve the shortcoming of the long construction cycle of constructed wetlands.

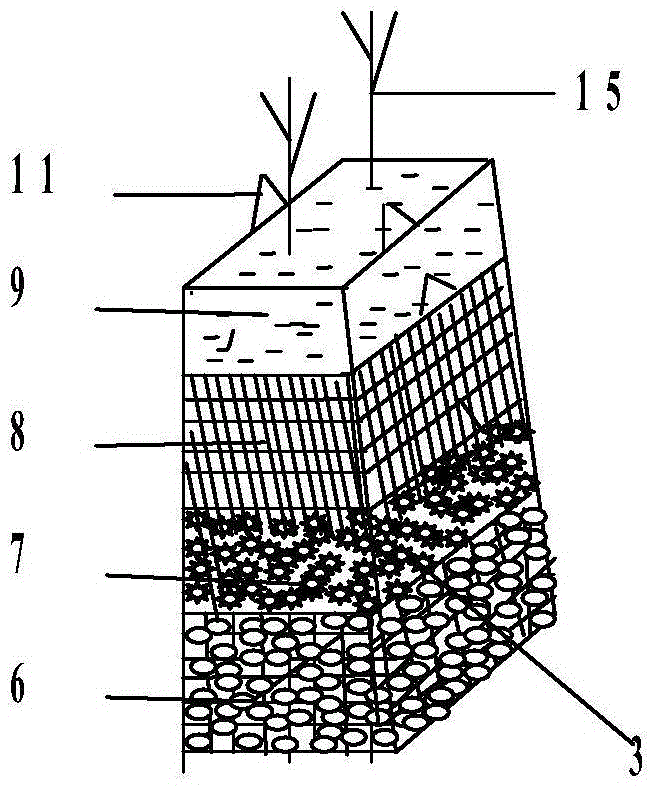

[0025] Such as figure 1 As shown, module one 1 is located at the water inlet, wherein each module includes a cubic frame 12, and matrix unit one 3, matrix unit two 4 and matrix unit three with pull ring one 11 on the top are sequentially arranged in the frame 12 along the water flow direction 5. Among them, matrix unit 1 3, matrix unit 2 4 and matrix unit 3 5 are packing block 1 6, packing block 2 7, packing block 3 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com