Fluorescent material and preparation method thereof

A fluorescent material and a manufacturing method technology, applied in the field of fluorescent materials, can solve the problem that N-based fluorescent materials cannot be near-ultraviolet LED chip luminescent materials, and achieve the effects of good product consistency, environmental friendliness, and high color reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

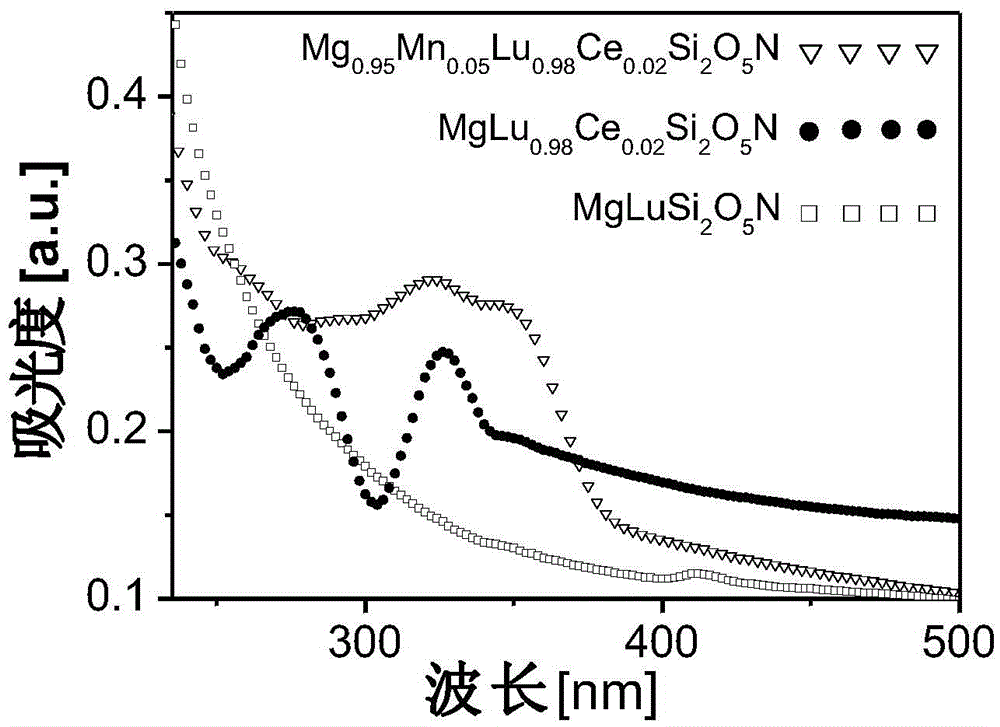

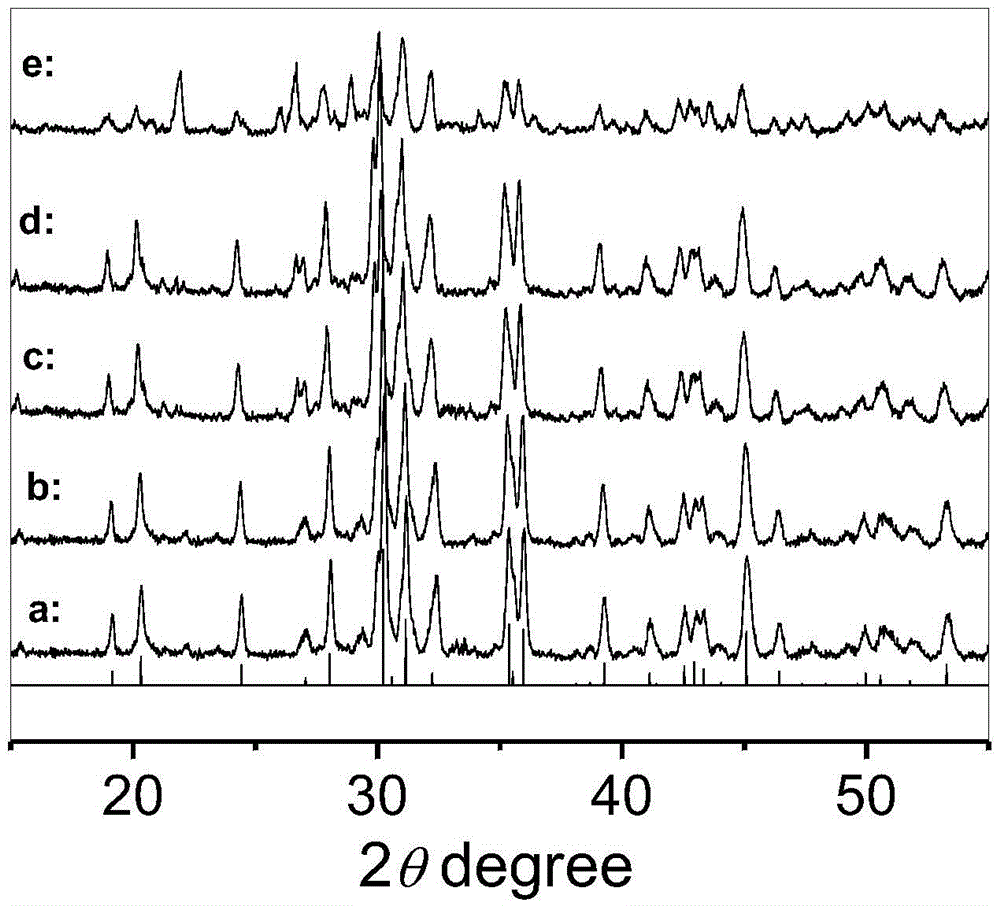

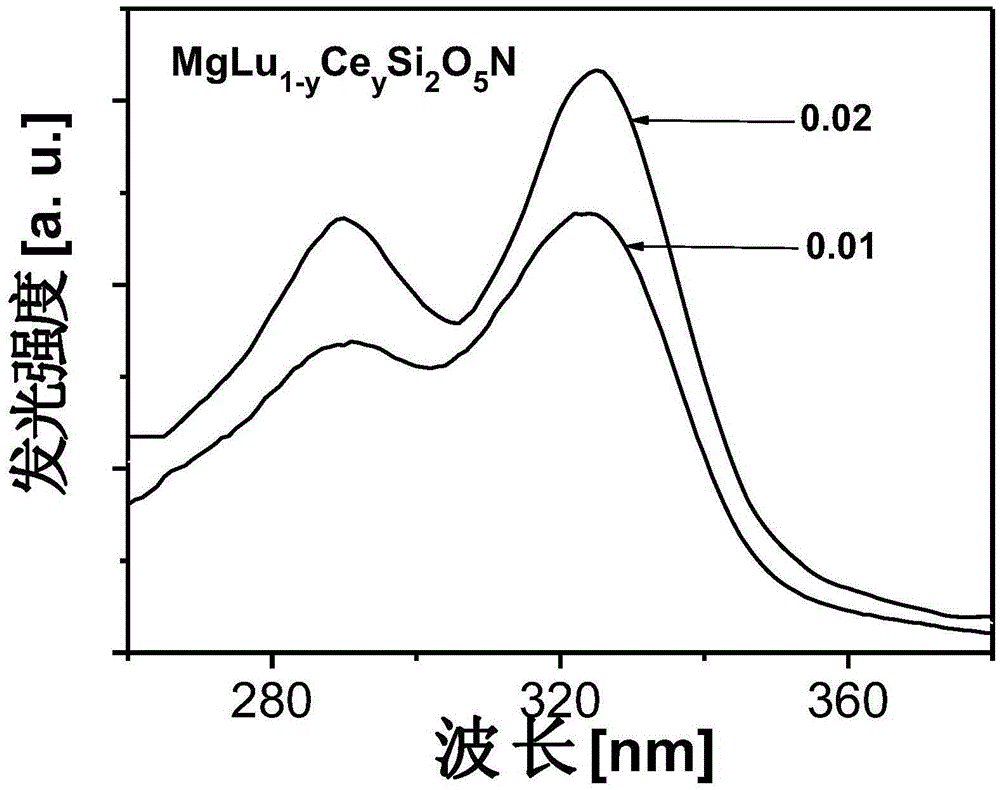

[0055] Preparation of Ce 3+ Single-doped fluorescent material MgLu 0.98 Si 2 o 5 N: 0.02Ce 3+ .

[0056] The general chemical formula of the fluorescent material is Mg 1-x Lu 1-y Si 2 o 5 N:yCe 3+ , xMn 2+ , means Mn 2+ 、Ce 3+ The x and y of the component ratio take the values of x=0 and y=0.02 respectively, then the general chemical formula is MgLu 0.98 Si 2 o 5 N: 0.02Ce 3+ , which can also be expressed as MgLu 0.98 Ce 0.02 Si 2 o 5 N. According to the chemical formula MgLu 0.98 Si 2 o 5 N: 0.02Ce 3+ For every 100 grams of sample, weigh 11.56 grams of analytically pure MgO and 11.56 grams of analytically pure Si 3 N 4 10.06 grams, the purity is analytically pure SiO 2 21.54 g, the purity is analytically pure CeO 2 0.99 g, analytically pure Lu 2 o 3 55.91 grams. Put the above weighed MgO, Si 3 N 4 , SiO 2 , CeO 2 、Lu 2 o 3 , MnCO 3 Put into the Si built in the grinding device 3 N 4 Grind in a mortar made of high-quality materials, use ...

Embodiment 2

[0061] Preparation of Mn 2+ 、Ce 3+ Co-doped fluorescent material Mg 0.9 Lu 0.98 Si 2 o 5 N: 0.002Ce 3+ , 0.1Mn 2+ .

[0062] The general chemical formula of the fluorescent material is Mg 1-x Lu 1-y Si 2 o 5 N:yCe 3+ , xMn 2+ , means Mn 2+ 、Ce 3+ The values of x and y of the component ratio are respectively x=0.1 and y=0.02, then the general chemical formula is Mg 0.9 Lu 0.98 Si 2 o 5 N: 0.02Ce 3+ , 0.1Mn 2+ , which can also be expressed as Mg 0.9 mn 0.1 Lu 0.98 Ce 0.02 Si 2 o 5 N. According to the chemical formula Mg 0.9 Lu 0.98 Si 2 o 5 N: 0.02Ce 3+ , 0.1Mn 2+ For every 100 grams of sample, weigh 10.29 grams of analytically pure MgO and 10.29 grams of analytically pure Si 3 N 4 9.95 grams of analytically pure SiO 2 21.31 grams, the purity is analytically pure CeO 2 0.1 g, analytically pure Lu 2 o 3 56.34 grams of analytically pure MnCO 3 3.26 grams. Put the above weighed MgO, Si 3 N 4 , SiO 2 , CeO 2 、Lu 2 o 3 , MnCO 3 Put int...

Embodiment 3

[0065] Preparation of Mn 2+ 、Ce 3+ Co-doped fluorescent material Mg 0.9 Lu 0.995 Si 2 o 5 N: 0.005Ce 3+ , 0.1Mn 2+ .

[0066] The general chemical formula of the fluorescent material is Mg 1-x Lu 1-y Si 2 o 5 N:yCe 3+ , xMn 2+ , where Mn 2+ 、Ce 3+ The values of x and y of the component ratio are respectively x=0.1 and y=0.005, then the general chemical formula is Mg 0.9 Lu 0.995 Si 2 o 5 N: 0.005Ce 3+ , 0.1Mn 2+ , which can also be expressed as Mg 0.9 mn 0.1 Lu 0.995 Ce 0.005 Si 2 o 5 N. According to the chemical formula Mg 0.9 Lu 0.995 Si 2 o 5 N: 0.005Ce 3+ , 0.1Mn 2+ For every 100 grams of sample, weigh 10.30 grams of analytically pure MgO and 10.30 grams of analytically pure Si 3 N 4 9.53 grams, the purity is analytically pure SiO 2 21.32 grams, the purity is analytically pure CeO 2 0.24 g, analytically pure Lu 2 o 3 56.19 grams of analytically pure MnCO 3 3.26 grams. Put the above weighed MgO, Si 3 N 4 , SiO 2 , CeO 2 、Lu 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com