Thermal treatment method and equipment for manufacturing aluminum-alloy automobile steering knuckle

A technology for automobile steering knuckle and cast aluminum alloy, which is applied in the field of heat treatment of cast aluminum alloy automobile steering knuckle, and can solve the problems of no solid solution temperature, solid solution time and optimal combination of aging temperature and solid solution time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

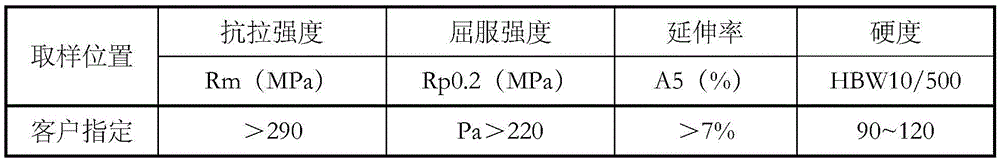

Embodiment 1

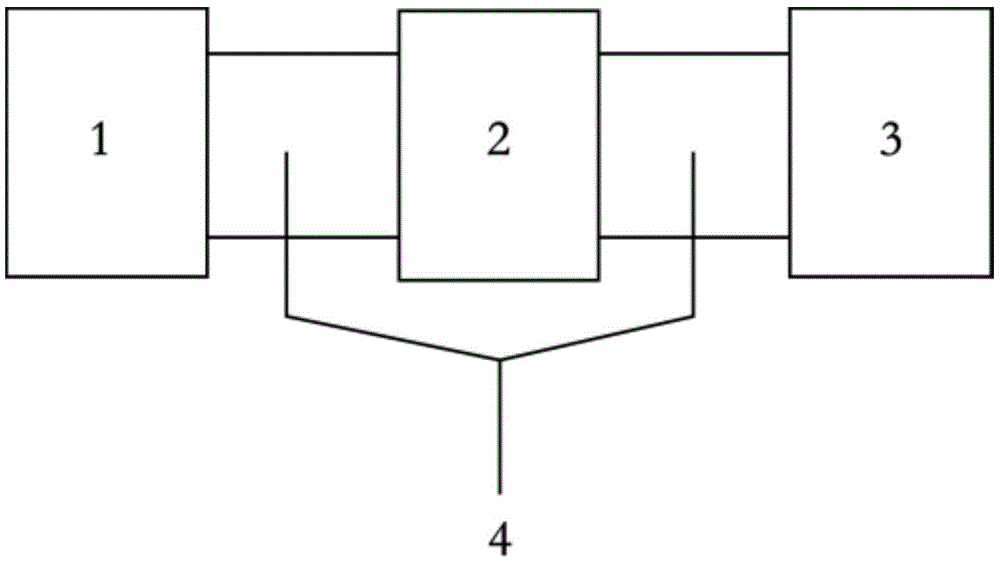

[0027] The device used for heat treatment of aluminum alloy automobile steering knuckle castings includes: solid melting furnace (1), quenching water tank (2), aging furnace (3) and transmission device (4) of aluminum alloy automobile steering knuckle, characterized in that: The solid melting furnace (1), quenching water tank (2) and aging furnace (3) are sequentially connected by the transmission device (4) of the aluminum alloy automobile steering knuckle; the transmission device (4) of the aluminum alloy automobile steering knuckle is set to In the solid melting furnace, the aluminum alloy steering knuckle casting reaches 537-547°C and is kept in the solid melting furnace for 330 minutes; after entering the quenching water tank, it stays in the middle for 180 seconds; and in the aging furnace, the temperature of the aluminum alloy steering knuckle reaches 153-163°C Afterwards, heat preservation in an aging furnace for 240 minutes. The transmission device (4) of the aluminum...

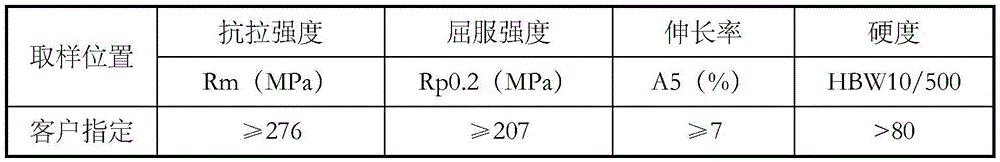

Embodiment 2

[0034] The device used for heat treatment of aluminum alloy automobile steering knuckle castings includes: solid melting furnace (1), quenching water tank (2), aging furnace (3) and transmission device (4) of aluminum alloy automobile steering knuckle, characterized in that: The solid melting furnace (1), quenching water tank (2) and aging furnace (3) are sequentially connected by the transmission device (4) of the aluminum alloy automobile steering knuckle; the transmission device (4) of the aluminum alloy automobile steering knuckle is set to In the solid melting furnace, the aluminum alloy steering knuckle casting reaches 537-547°C and is kept in the solid melting furnace for 330 minutes; after entering the quenching tank, it stays for 180 seconds; and in the aging furnace, the temperature of the aluminum alloy steering knuckle reaches 153-163°C Afterwards, heat preservation in an aging furnace for 240 minutes. The transmission device (4) of the aluminum alloy automobile st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com