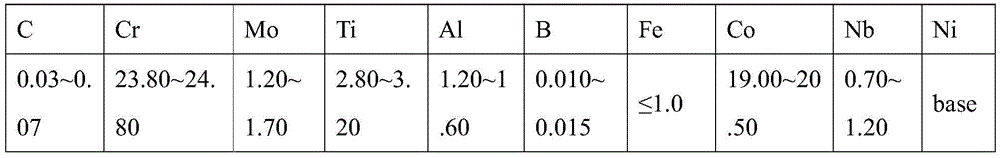

Heat treatment method for Nimonic101 nickel-based alloy

A heat treatment method and technology for nickel-based alloys, applied in the field of alloy heat treatment, can solve the problem that the room temperature tensile strength cannot meet the acceptance requirements, etc., and achieve the improvement of room temperature elongation and section shrinkage rate, and improve room temperature tensile strength and yield strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

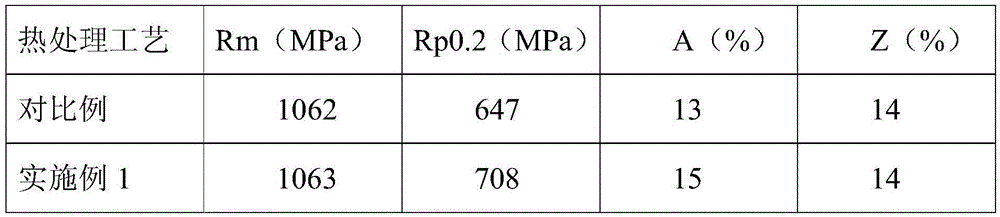

Embodiment 1

[0020] Example 1: The Nimonic101 nickel-based alloy is subjected to solution heat treatment. The solution heat treatment temperature is 1125°C. After heat penetration, it is kept for 4 hours. After the heat preservation is completed, it is taken out of the furnace and air-cooled to room temperature; Heat treatment, after heat penetration, heat preservation for 16 hours, after heat preservation, take out of the furnace and air cool to room temperature; after air cooling, Nimonic101 nickel-based alloy forgings are subjected to aging heat treatment at 850°C, after heat penetration, heat preservation for 16 hours, after heat preservation, come out of the furnace and air cool to room temperature, Nimonic101 nickel-based alloy was prepared.

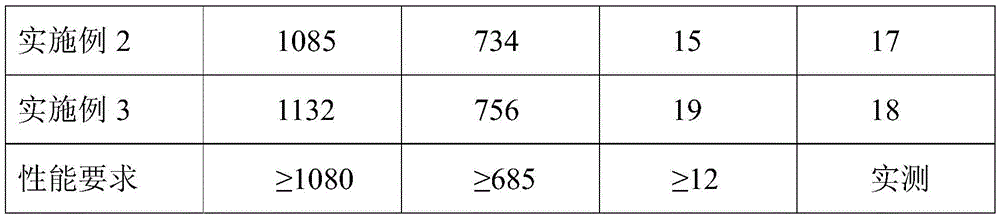

Embodiment 2

[0021] Example 2: The Nimonic101 nickel-based alloy forging is subjected to solution heat treatment, the solution heat treatment temperature is 1125 ° C, and it is kept warm for 4 hours after heat penetration. Intermediate heat treatment, after heat penetration, heat preservation for 16 hours, after heat preservation, take out the furnace and air cool to room temperature; after air cooling, Nimonic101 nickel-based alloy forgings are subjected to aging heat treatment at 850 ° C, after heat penetration, heat preservation for 16 hours, after heat preservation, take out the furnace and air cool to room temperature , made Nimonic101 nickel-based alloy.

Embodiment 3

[0022] Example 3: The Nimonic101 nickel-based alloy forging is subjected to solution heat treatment. The solution heat treatment temperature is 1125 ° C. After heat penetration, it is kept for 4 hours. After the heat preservation is completed, it is taken out of the furnace and air-cooled to room temperature. Intermediate heat treatment, after heat penetration, heat preservation for 16 hours, after heat preservation, take out the furnace and air cool to room temperature; after air cooling, Nimonic101 nickel-based alloy forgings are subjected to aging heat treatment at 850 ° C, after heat penetration, heat preservation for 16 hours, after heat preservation, take out the furnace and air cool to room temperature , made Nimonic101 nickel-based alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com