A dust scraping device for batch hot-dip galvanizing

A hot-dip galvanizing, batch technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem of hindering the movement of the scraper, the size of the workpiece to be plated, the complexity of the shape, the inclusion of zinc particles, etc. problem, to achieve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

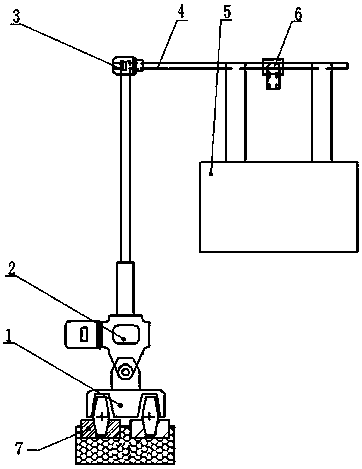

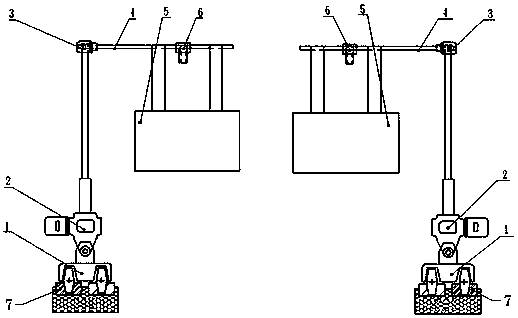

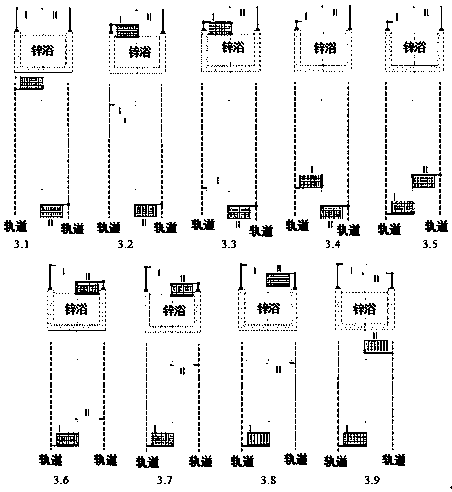

[0028]The dust scraping device for batch hot-dip galvanizing described in this embodiment includes an electric trolley 1, an electric push rod 2, a reduction motor 3, a rotating shaft 4, a scraper 5 and an infrared detector 6, and the lower end of the electric push rod 2 is fixed on the electric trolley 1, the deceleration motor 3 is fixed on the upper end of the electric push rod 2; the output shaft of the deceleration motor 3 is connected with the rotating shaft 4, and the scraper 5 and the infrared detector 6 are installed under the rotating shaft 4; the probe 61 of the infrared detector 6 and the scraper The board face 51 of plate 5 is on a plane; The board face width of scraper 5 is 5 centimeters larger than half of the zinc pot width. The distance from the probe of the infrared detector 6 to the surface of the zinc bath is 2 mm smaller than the distance from the probe of the infrared detector 6 to the lowermost edge of the scraper 5 during the ashing operation. When the ...

Embodiment 2

[0031] The dust scraping device for batch hot-dip galvanizing described in this embodiment includes an electric trolley 1, an electric push rod 2, a reduction motor 3, a rotating shaft 4, a scraper 5 and an infrared detector 6, and the lower end of the electric push rod 2 is fixed on the electric trolley 1, the deceleration motor 3 is fixed on the upper end of the electric push rod 2; the output shaft of the deceleration motor 3 is connected with the rotating shaft 4, and the scraper 5 and the infrared detector 6 are installed under the rotating shaft 4; the probe 61 of the infrared detector 6 and the scraper The plate surface 51 of the plate 5 is on a plane; the plate surface width of the scraper 5 is 10 centimeters larger than half of the zinc pot width. The distance from the probe of the infrared detector 6 to the surface of the zinc bath is 1 mm smaller than the distance from the probe of the infrared detector 6 to the bottom edge of the scraper 5 during the dusting operati...

Embodiment 3

[0034] The dust scraping device for batch hot-dip galvanizing described in this embodiment includes an electric trolley 1, an electric push rod 2, a reduction motor 3, a rotating shaft 4, a scraper 5 and an infrared detector 6, and the lower end of the electric push rod 2 is fixed on the electric trolley 1, the deceleration motor 3 is fixed on the upper end of the electric push rod 2; the output shaft of the deceleration motor 3 is connected with the rotating shaft 4, and the scraper 5 and the infrared detector 6 are installed under the rotating shaft 4; the probe 61 of the infrared detector 6 and the scraper The board face 51 of plate 5 is on a plane; The board face width of scraper 5 is 8 centimeters larger than half of the zinc pot width. The distance from the probe of the infrared detector 6 to the surface of the zinc bath is 1.5 mm smaller than the distance from the probe of the infrared detector 6 to the lowermost edge of the scraper 5 during the dusting operation; when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com