A sliding device for removing the side formwork of the cast-in-place box girder of the bracket and its application method

A technology of sliding device and application method, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve problems such as increasing construction costs, damage to box girders or formwork, and affecting work efficiency, so as to save construction costs and improve project quality , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the accompanying drawings, the present invention will be further described, but not as a limitation of the present invention.

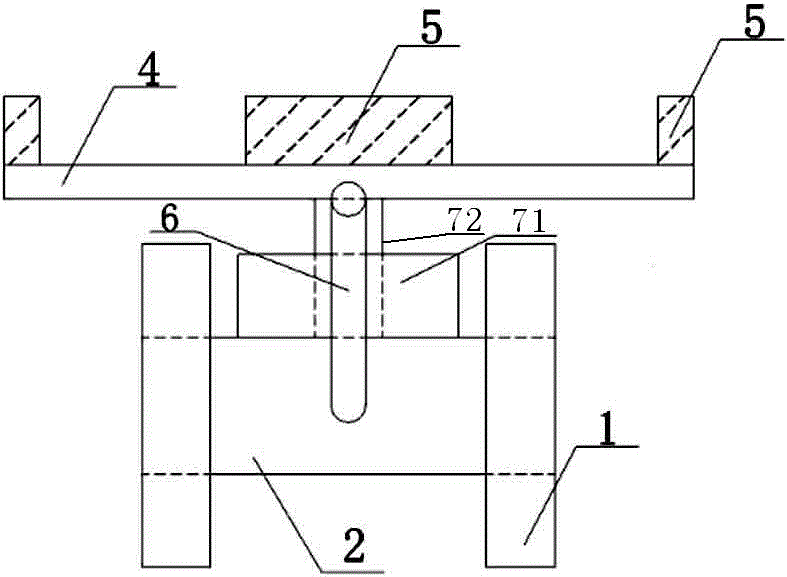

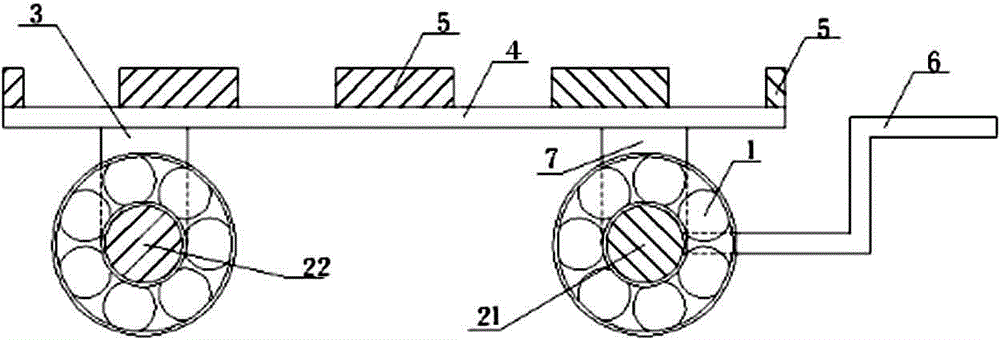

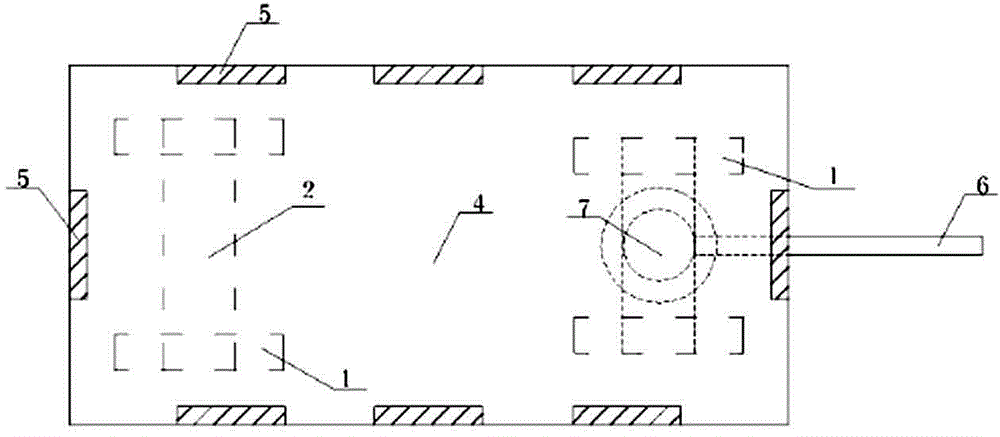

[0023] A sliding device for removing the side formwork of a cast-in-place box girder, including a slideway and a mobile trolley that cooperates with it; the mobile trolley includes a roller 1, a wheel shaft 2, a wheel frame 3, a load-bearing panel 4, a positioning baffle 5, a steering rod 6 and Steering shaft 7, wherein: the wheel shaft includes a front wheel shaft 21 and a rear wheel shaft 22, the two sides of the front wheel shaft 21 and the rear wheel shaft 22 respectively pass through the roller 1 and form a rolling fit; the middle part of the front wheel shaft 21 fixes the vertical steering shaft 7 upwards, 7. The steering shaft includes a fixed sleeve 71 directly fixed on the top of the front wheel shaft 21 and a rotating column 72 that is sleeved in the fixed sleeve 71 and rotates with it; the front wheel shaft 21 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com