A kind of hole-forming pile-forming equipment and construction method

A piling and equipment technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as difficulty in ensuring smooth implementation and construction quality, shrinkage and collapse holes, and difficulty in forming holes and piling. Improve pile quality and construction efficiency, improve comprehensive economic and social benefits, and avoid hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

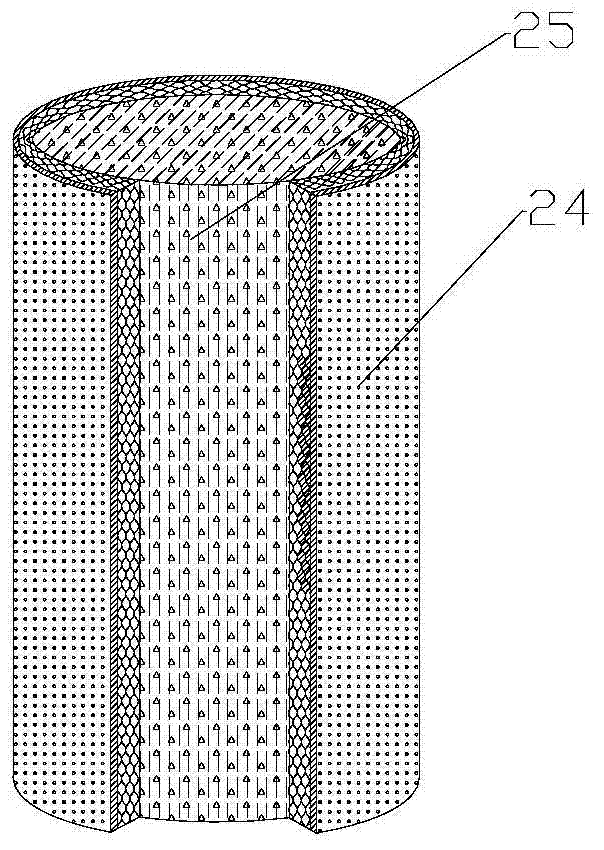

[0028] This embodiment is mainly designed for the construction of a composite net tube granular material pile, the structure of the net tube granular material is as follows image 3 As shown, it is composed of an outer mesh cylinder 24 and an inner pile body 25 densely filled with granular materials, which can not only add surrounding enclosure measures to the traditional granular pile body, but also weaken or eliminate the stress dissipation of the traditional pile body effect, which significantly improves the stress state and capacity of the pile body. At the same time, because the outer mesh cylinder 24 has a smooth drainage channel, the pile body can also have a strong and durable drainage capacity, which significantly improves the consolidation speed of the soft soil. The degree of consolidation and the ability to continue to mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com