Damping ditch with pressure relief device and shockproof plates and construction method for damping ditch

A pressure relief device and anti-vibration plate technology, which is applied in protection devices, infrastructure engineering, construction, etc., can solve the problems of no internal support system, inconspicuous effect of shock-absorbing trenches, difficult vibration reduction and isolation, etc., to achieve enhanced shock absorption and shock-isolation effect, improve shock-absorbing and shock-isolation effect, improve shock-absorbing and shock-isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

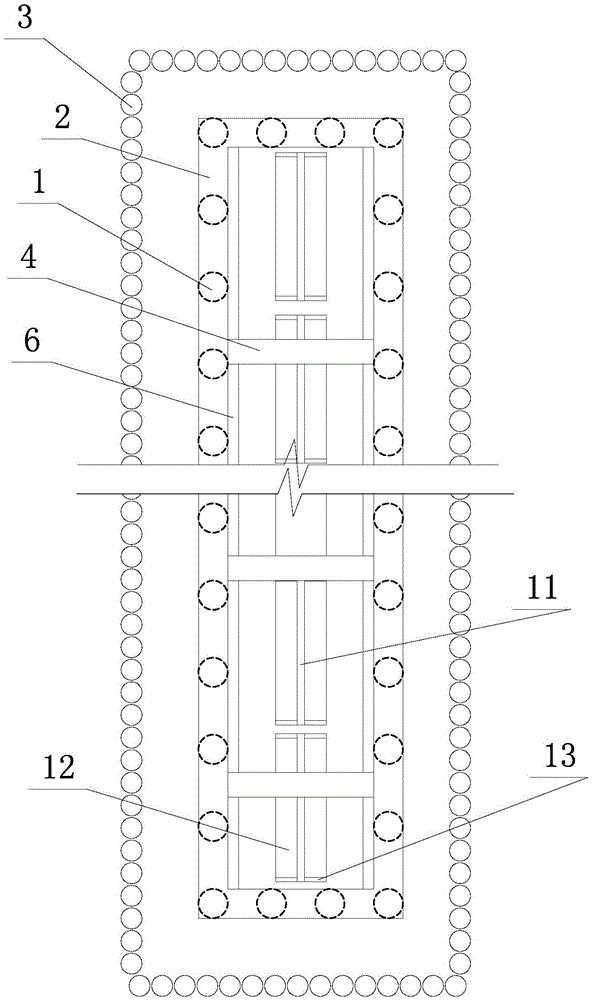

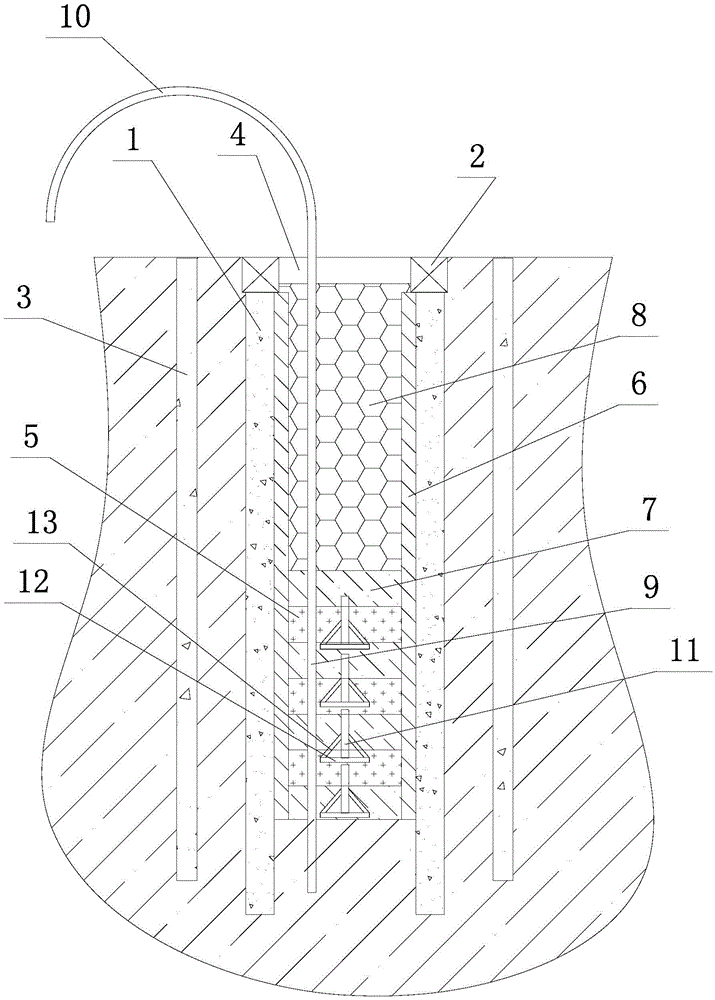

[0027] Such as figure 1 , figure 2 As shown, the shock-absorbing ditch with pressure relief device and shockproof plate of the present invention includes a circle of support piles 1 and a circle of pressure beams 2 that are poured on the top of each support pile 1 to connect each support pile 1 into a whole . The support pile 1 generally adopts the bored cast-in-place pile. The ring support piles 1 include two rows of support piles 1 extending along the length direction of the shock absorbing ditch and two rows of support piles 1 extending along the width direction of the shock absorbing ditch; the above four rows of support piles 1 are connected end to end in a circle, Constitutes the profile of the damping ditch.

[0028] The outer side of the ring support pile 1 is provided with a circle of cement-soil mixing pile 3 to form a water-stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com