Combined thermal shielding structure for vertical pump for conveying high-temperature medium

A high-temperature medium and heat shielding technology, applied in the direction of non-variable pumps, non-volume pumps, special fluid pumps, etc., can solve the limited heat insulation effect of the vacuum chamber, the temperature rise of the sealing mechanism, and damage to the pump sealing structure, etc. problem, to achieve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

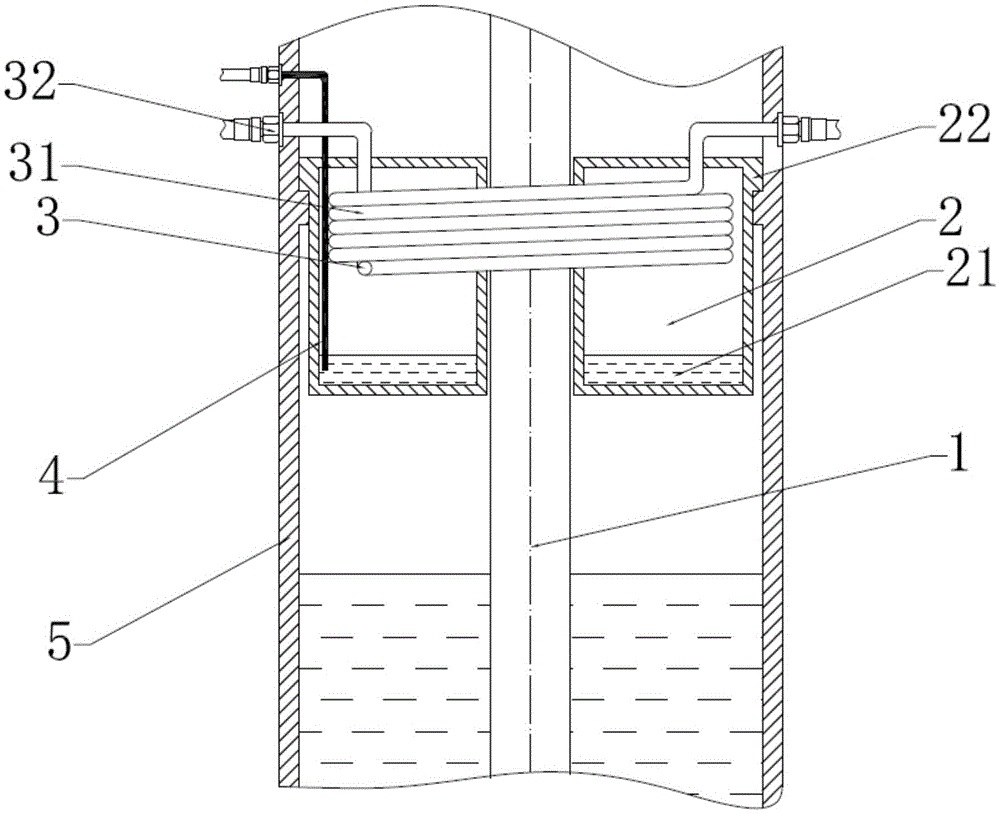

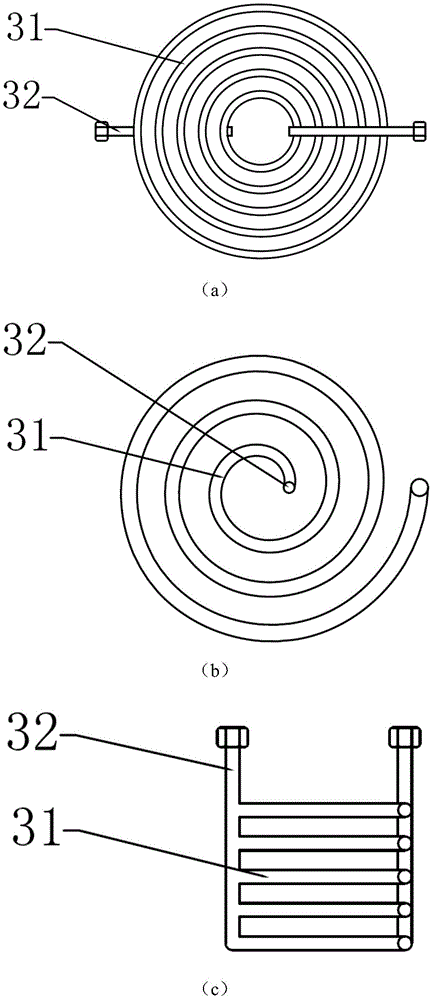

[0022] The main features of Embodiment 1 are: a combined heat shield structure for vertical pumps conveying high-temperature media, such as Figure 1-2 As shown, it includes a pump shaft 1 , a low-pressure heat pipe 2 , a forced circulation heat exchange device 3 , a liquid level gauge 4 and a pump casing 5 . The low-pressure heat pipe 2 includes a cooling medium 21 in the heat pipe wall and a heat pipe wall 22. The forced circulation heat exchange device 3 includes a heat exchange pipe 31 and a heat exchange pipe outlet 32. The heat shielding structure is installed in a vertical mechanical pump. It is a submerged pump for transporting high temperature liquid metal. The lower end of the heat shielding structure is a high-temperature liquid metal, and the upper end of the heat shielding structure is other components such as the shaft seal of the pump. The heat of the liquid metal at the lower end is transferred to the low-pressure heat pipe 2 of the heat-shielding structure. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com