Heat exchanger realizing pipe communication of heating pipes

A heating pipe and heat exchanger technology, applied in the field of HVAC, can solve the problems of small heat exchange area, low heat exchange efficiency and high cost of the heat exchanger, and achieve advanced technology, large heat exchange area and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

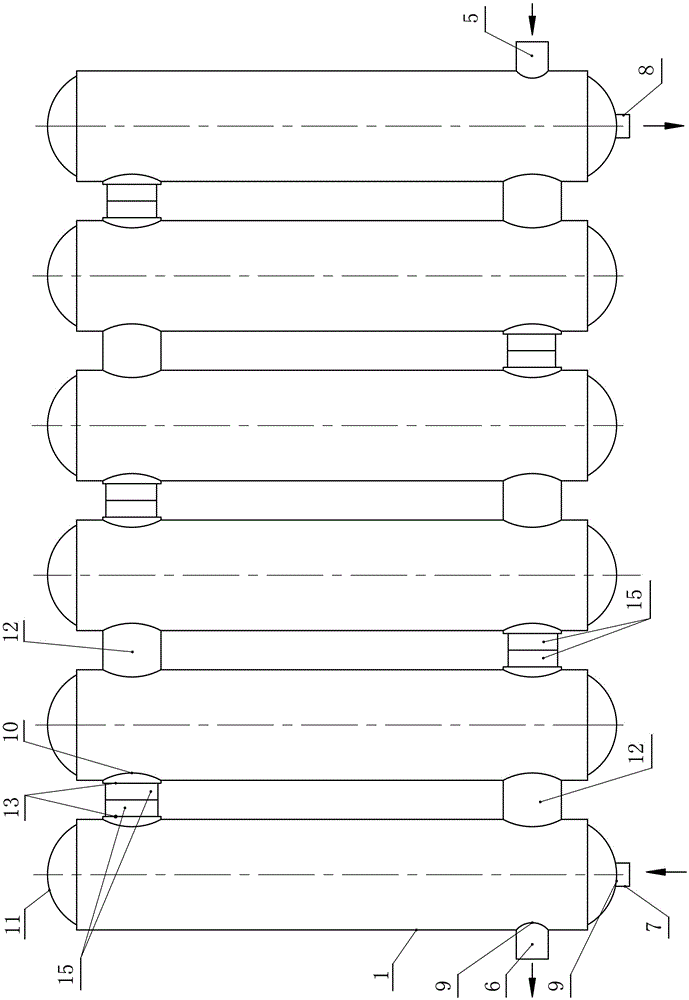

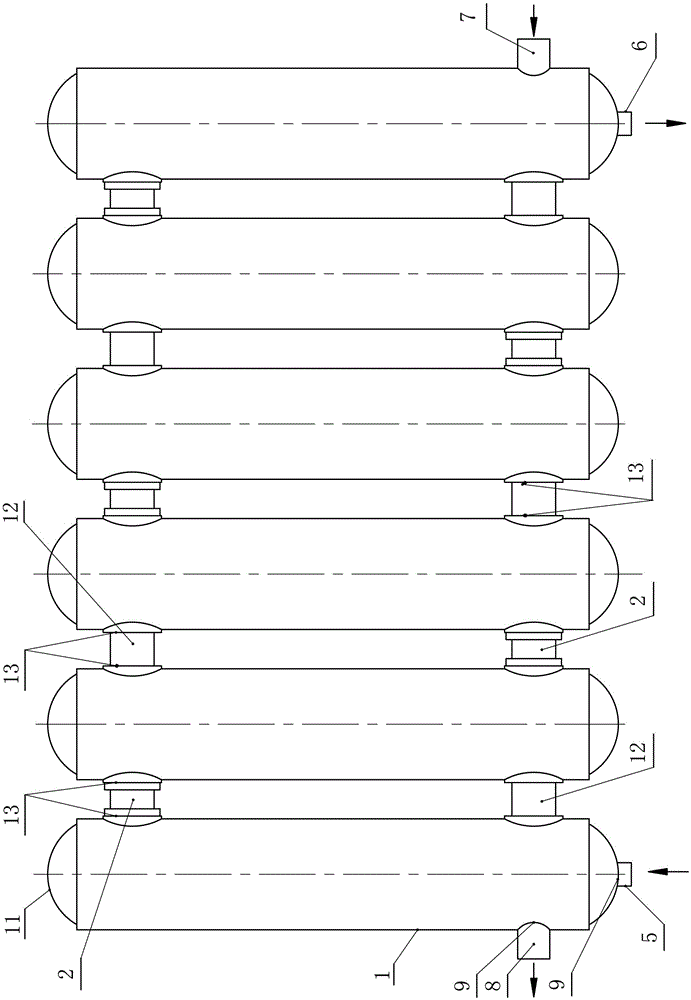

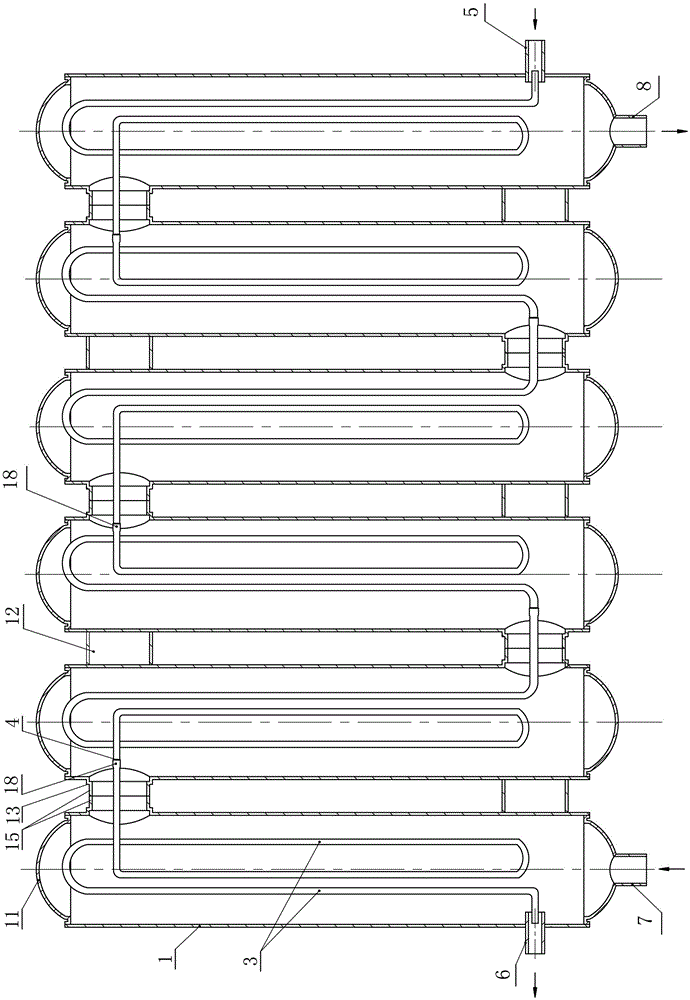

[0028] 1. The heating pipe of the present invention connects the heat exchanger such as Figure 1-18As shown, it includes: multiple heating pipes 1, end blocking plates 11, heating straight pipes 2, wall pipes 15, support members 12, cold water heat exchange pipes 3, notch connecting plates 22, pipe joint parts assembled and welded It is a heat exchanger in the shape of a radiator; some parts of the heat exchanger are provided with pipe joint welding ports 9 to facilitate the installation and welding of pipe joints; or some parts of the heat exchanger are not provided with pipe joint welding ports 9; Pipe joint Ⅳ8, cold water inlet pipe joint Ⅰ5, cold water outlet pipe joint Ⅱ6 and pipe joint welding port 9 on the heat exchanger parts are welded and connected to form a shell-side hot fluid channel or a tube-side cold fluid channel; it is charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com