Hydro-pneumatic spring test bench with side force simulation device

A technology of oil-gas spring and simulation device, which is applied in the direction of measuring device, mechanical component test, machine/structural component test, etc. The axis is not very good, the hinge is stuck, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

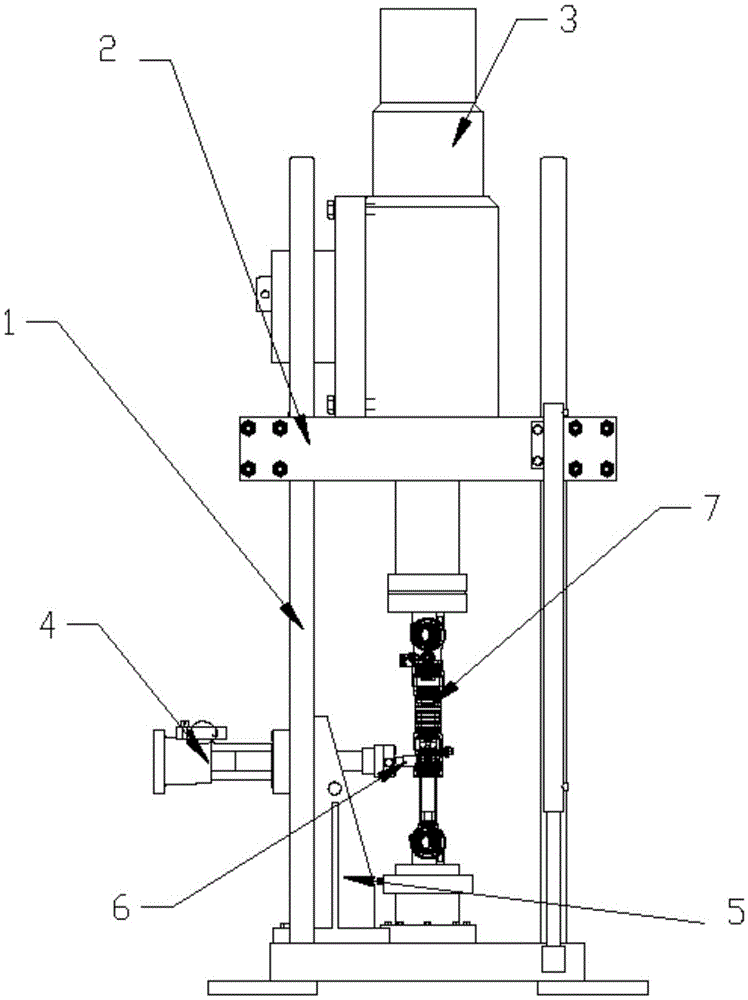

[0013] Such as figure 1 As shown, the oil-pneumatic spring test bench with lateral force simulation device in this embodiment includes: fixed frame 1 with vibration reduction, movable frame 2, axial load simulation hydraulic actuator 3, lateral force simulation Actuator 4, lateral force simulation actuator bracket 5, lateral force loading tooling 6, oil and gas spring 7, controller (not shown in the figure) and hydraulic system (not shown in the figure); The fixed frame 1 includes a bottom support table and four columns installed on the support table, and the bottom support table is placed on the workbench; the movable frame 2 is provided with through holes, and the through holes pass through the four columns respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com