A non-destructive testing device for rail based on magnetic flux leakage and induced current

A technology of induced current and non-destructive testing, applied in the direction of material magnetic variables, etc., can solve the problems of inability to detect internal defects, slow detection speed, etc., and achieve the effect of high-speed non-destructive testing and high flaw detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

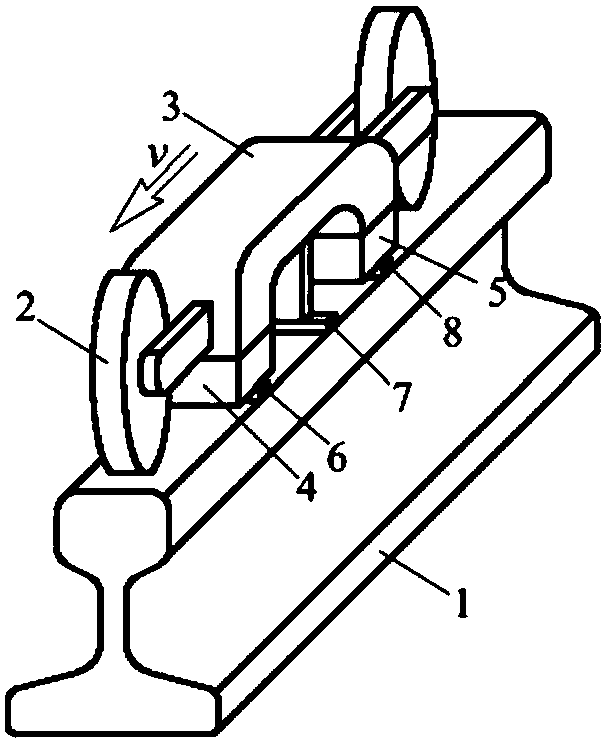

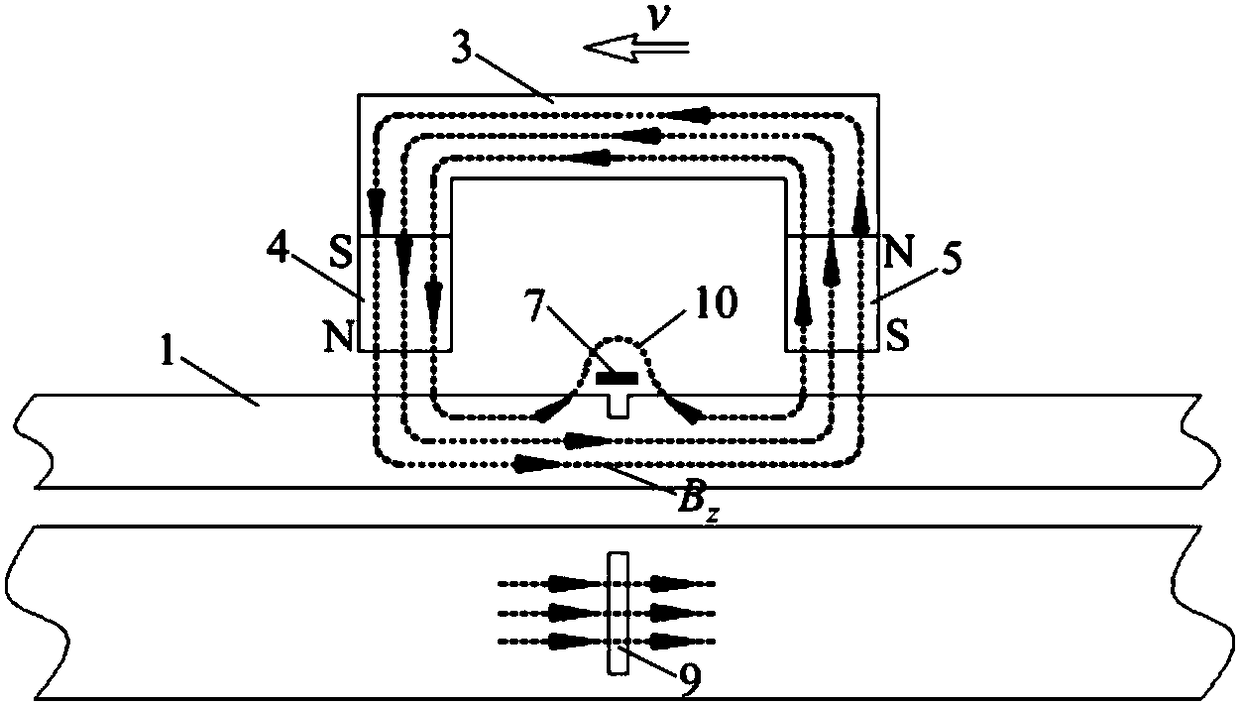

[0029] The rail non-destructive testing device based on magnetic flux leakage and induced current in this embodiment is a component of a special rail testing vehicle, such as figure 1 Shown. The structure of the rail nondestructive testing device includes the arc structure guide magnet 3, the permanent magnets 4 and 5 arranged at both ends of the arc structure guide magnet, the magnetic sensors 6, 7, and 8 arranged on the lower end surface of the permanent magnet and the central part of the arc structure guide magnet. , And the signal conditioning circuit 15, the acquisition card 16, and the computer 17. The permanent magnets arranged at both ends of the arc structure guide magnet, wherein the N end of the permanent magnet 5 is upward and the S end is downward, and the N end of the permanent magnet 4 is downward and the S end is upward. Two permanent magnets are formed with the steel rail to be tested and the arc structure guide magnet The magnetization circuit is closed to for...

Embodiment 2

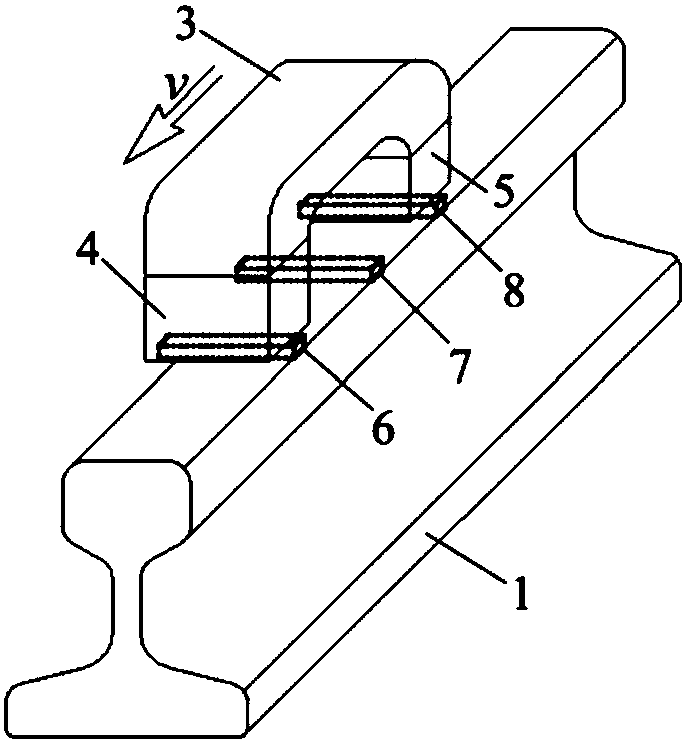

[0034] The structure and detection principle of the rail nondestructive testing device based on magnetic flux leakage and induced current of this embodiment is the same as that of Embodiment 1, except that the arc-shaped structure guide magnet 3 is provided with permanent magnets at both ends of the arc-shaped structure guide magnet. 4, 5, the main body of the detection device composed of the magnetic sensors 6, 7, and 8 arranged on the lower end surface of the permanent magnet and arranged in the middle of the guide magnet of the arcuate structure, is directly arranged in the train carriage (or the box body of other vehicles traveling on rails) Below, make it form a closed magnetization loop with the rail below, such as figure 2 Shown. As another part of the signal processing of the detection device, the signal conditioning circuit 15, the acquisition card 16 and the computer 17 connected in sequence are arranged in the train carriage, and the signal conditioning circuit 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com