Non-destructive method for evaluating aging and operation state of cables

An operating state, non-destructive technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve the problems of affecting insulation resistance measurement, restricting popularization and application, and cumbersome data processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

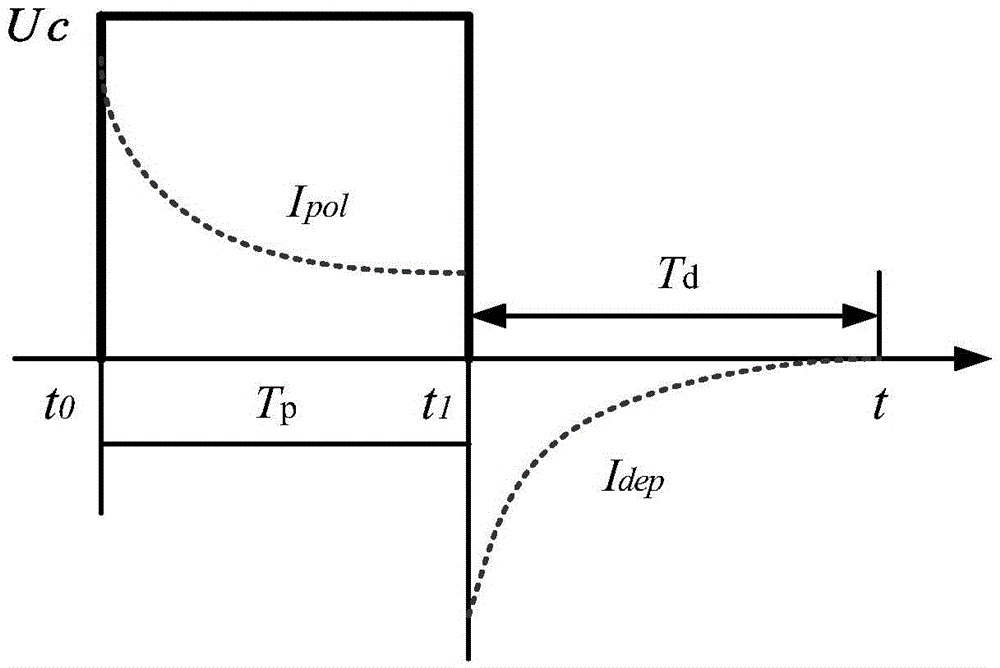

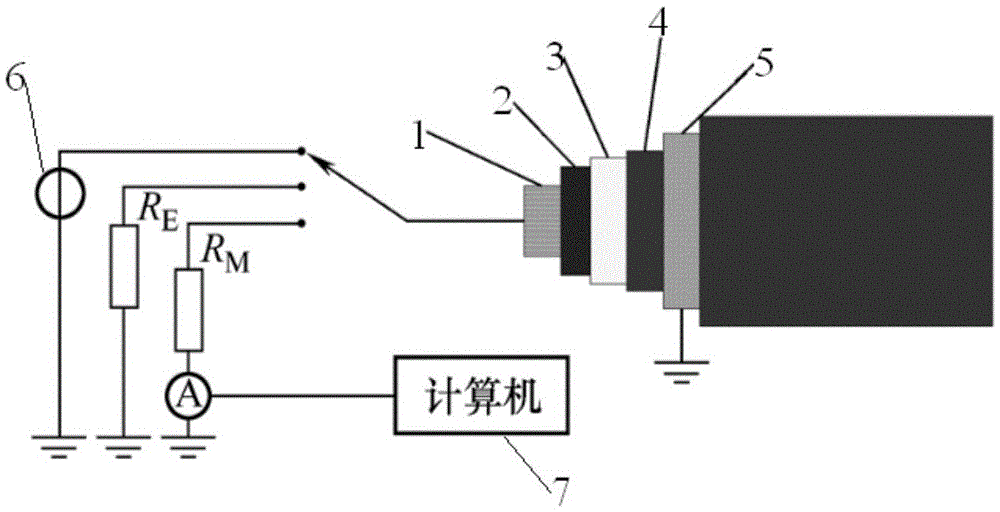

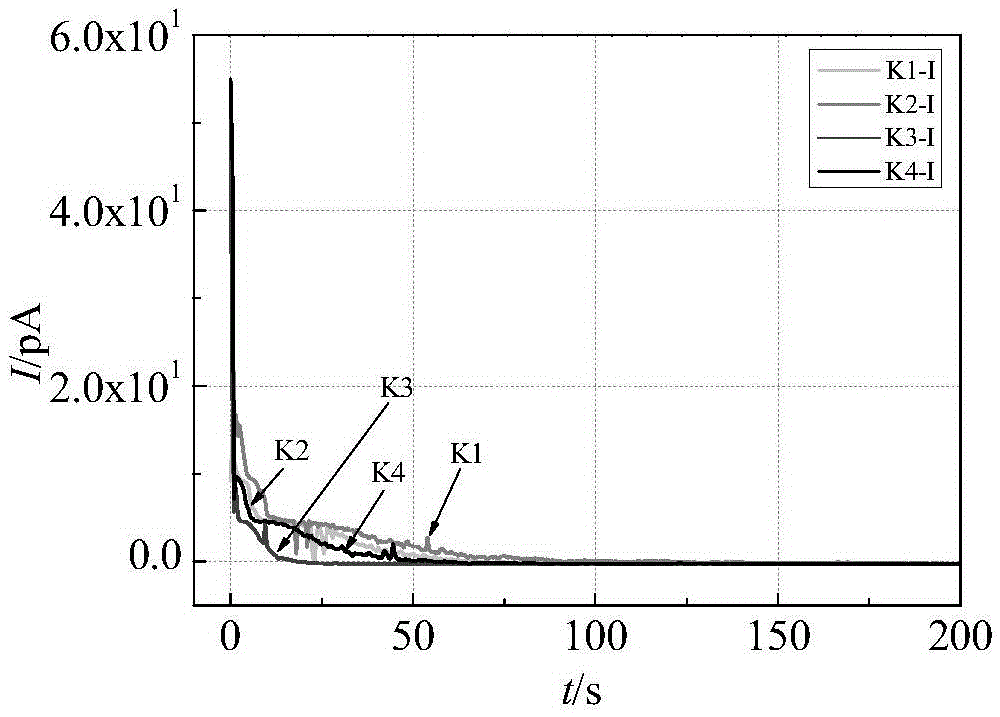

[0030] The present invention analyzes the relaxation current characteristics of the depolarization process of the 10kV new anti-water tree XLPE cables (hereinafter collectively referred to as K-type cables) and 10kV XLPE cables (hereinafter collectively referred to as P-type cables) after polarization, and adopts three methods: The order exponential function is used to perform numerical fitting analysis on the isothermal relaxation current curve, extract the relevant information inside the insulation such as trap distribution characteristics and polarization time constant, and calculate the polarization contribution and aging factor A of different relaxation processes. Based on the aging factor A, the cable to determine the remaining life of the device.

[0031] The following parameters were selected to characterize the running cable state, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com