Light emitting module of electronic equipment and manufacturing method thereof

A technology of electronic equipment and light-emitting modules, which is applied in the direction of illuminated signs, display devices, instruments, etc., and can solve problems such as unfavorable development of electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

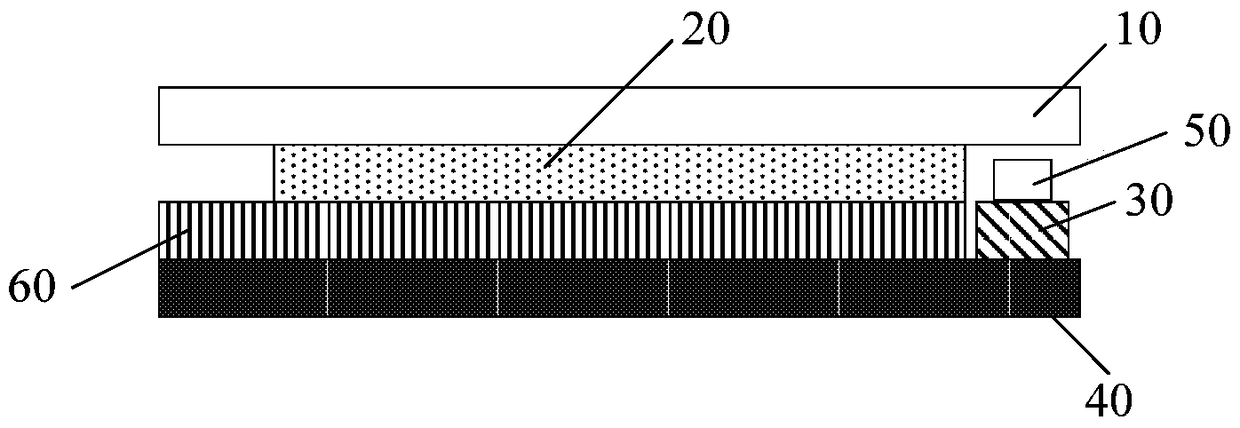

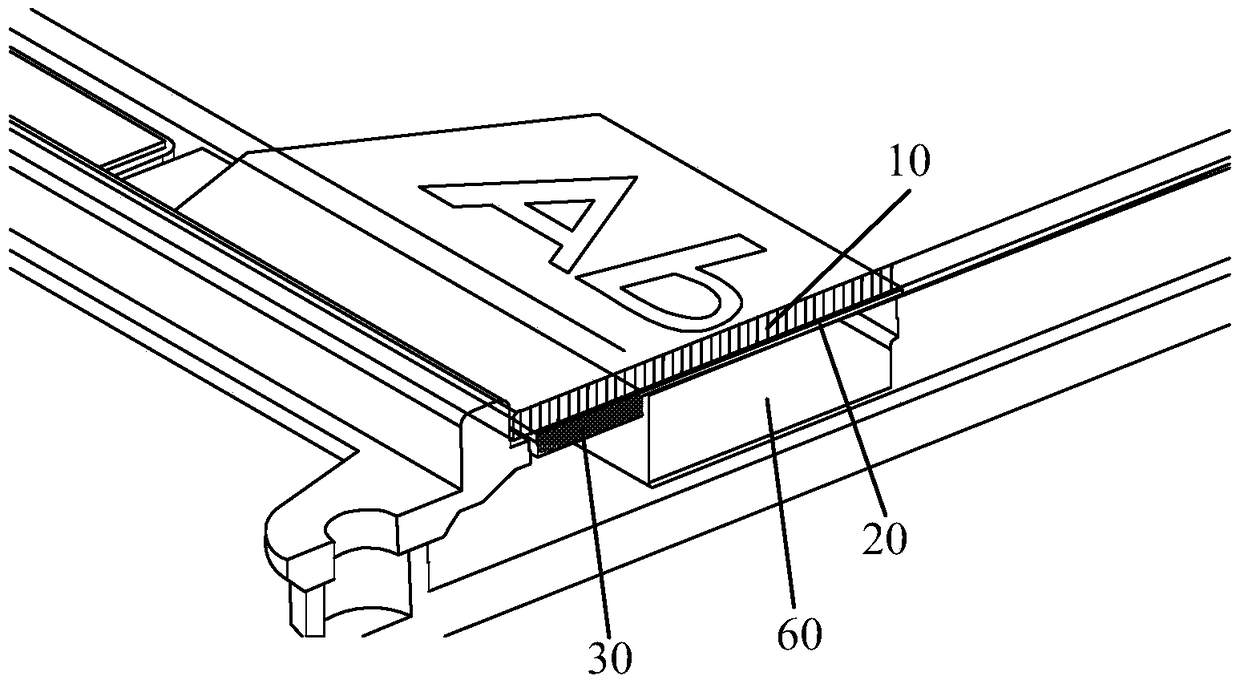

[0024] Embodiment 1 of the present invention provides a light-emitting device for electronic equipment, the light-emitting device includes a light-emitting module, such as figure 1 As shown, the light-emitting module includes: a light guide layer 20 and a PCB 30, the light guide layer 20 and the PCB 30 are arranged in a staggered position, and the PCB 30 is located in a side-by-side layer of the panel control board 60, and the guide The optical layer 20 is located above the panel control board 60 .

[0025] In order to thin the light-emitting module, the light guide layer 20 of the embodiment of the present invention can choose to use Mylar sheet, and the Mylar sheet refers to PET (polyethylene terephthalate) polyester film as the light guide layer. 20 Mylar sheet, its thickness can be 0.3mm (millimeter). Of course, the thickness of the Mylar sheet used as the light guide layer 20 is not limited to 0.3mm, and its thickness can be adjusted and selected according to actual prod...

Embodiment 2

[0033] Embodiment 2 of the present invention provides an electronic device, including the light-emitting device described in Embodiment 1 of the present invention, the light-emitting device includes a light-emitting module, the number of the light-emitting module is at least one, and the light-emitting module is set On at least one shell panel of the electronic device, or embedded in at least one shell panel of the electronic device.

Embodiment 3

[0035] Embodiment 3 of the present invention also provides a method for manufacturing a light-emitting module of an electronic device, including:

[0036] A PCB is arranged on a side-by-side layer located in the lateral direction of the panel control board, a light guide layer is arranged above the panel control board, and the light guide layer and the PCB are arranged in a dislocation manner.

[0037]Wherein, in order to thin the light-emitting module, the light guide layer of the embodiment of the present invention can choose to use Mylar sheet, and the Mylar sheet refers to PET (polyethylene terephthalate) polyester film, used as a light guide layer. The thickness of the layered Mylar sheet can be 0.3mm (millimeter). Of course, the thickness of the Mylar sheet used as the light guide layer is not limited to 0.3mm, and its thickness can be adjusted and selected according to actual product needs. For example, a Mylar sheet with a thickness of 0.3mm-0.5mm can be used as the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com