Pixel arrangement structure and manufacturing method thereof and display

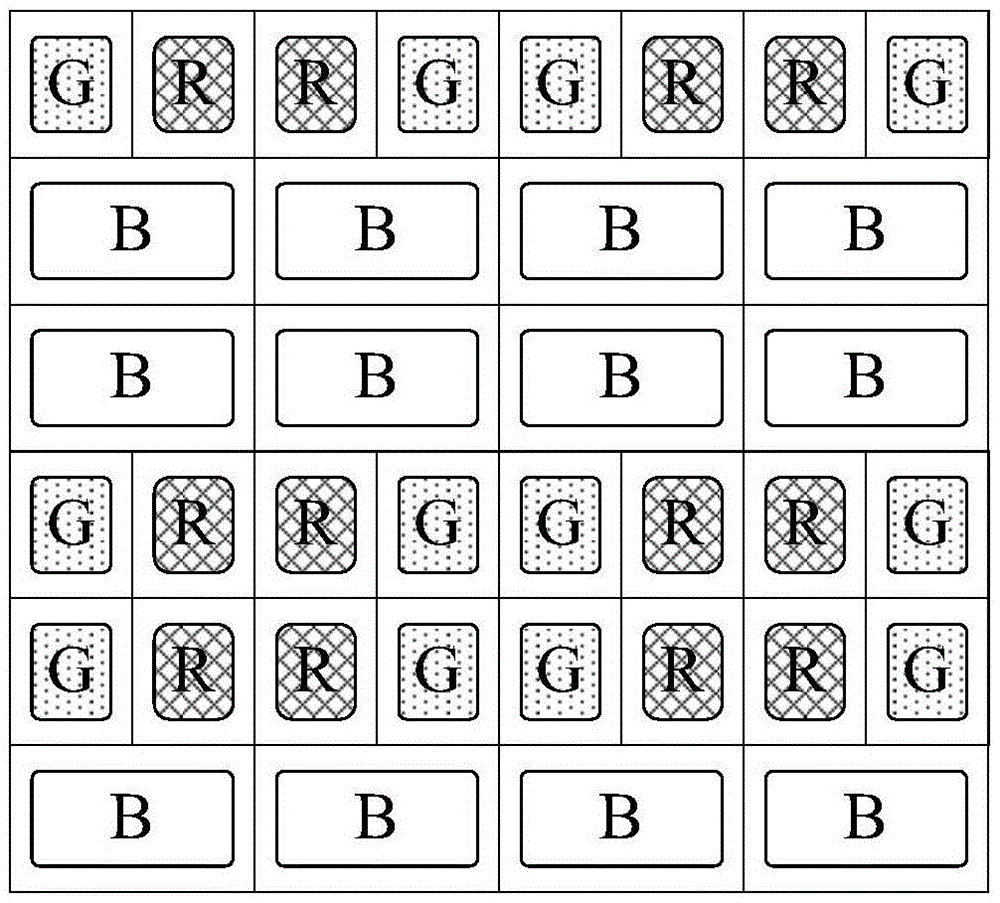

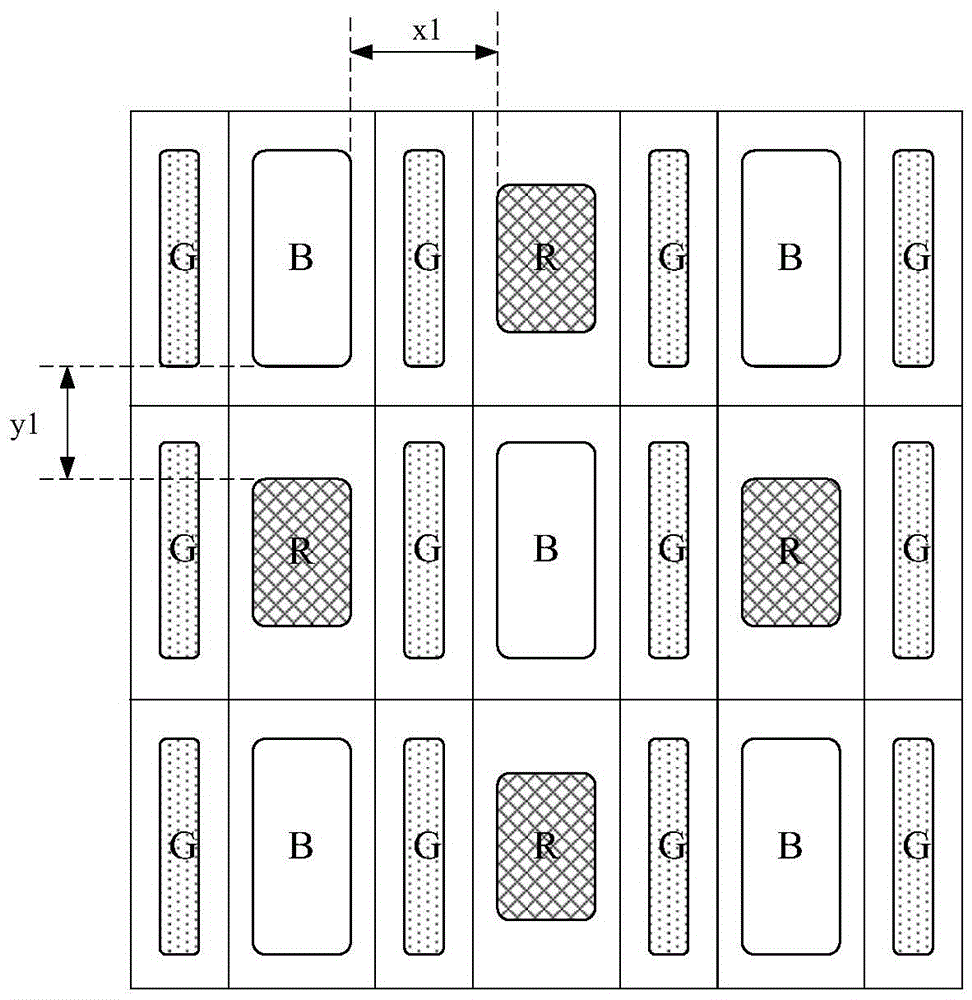

A pixel arrangement and manufacturing method technology, applied in the field of OLED display, can solve the problems of limiting the improvement of resolution and the ineffective use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Further description will be given below in conjunction with the accompanying drawings and embodiments.

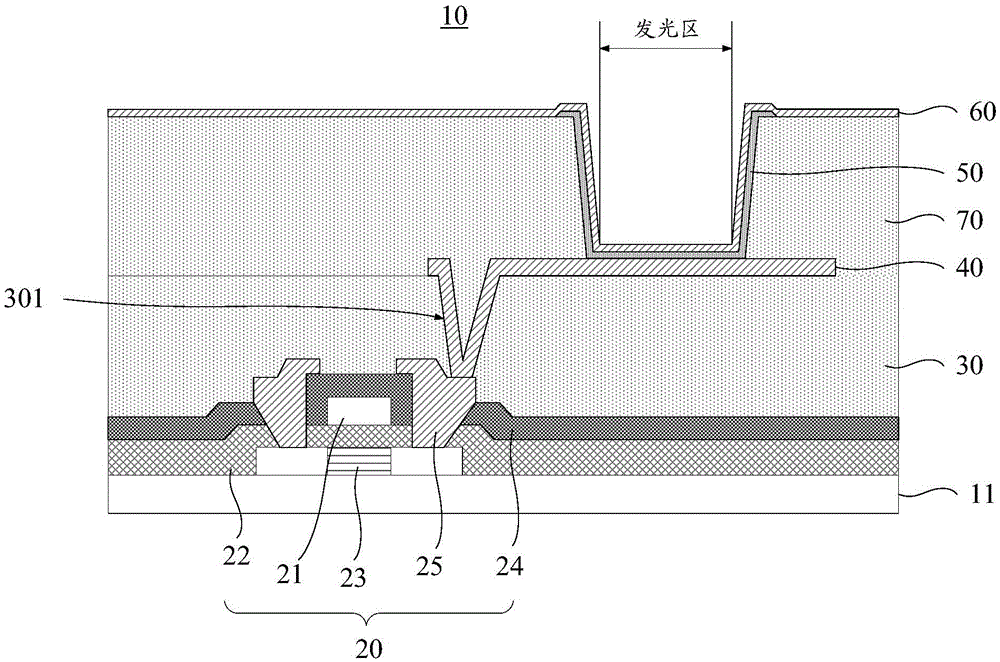

[0057] combine first Figure 3-5 Briefly explain the display principle of the self-luminous display.

[0058] image 3 A longitudinal sectional view of the organic light emitting display 10 is shown. The organic light emitting display 10 includes a substrate 11 , a driving layer 20 , a first insulating layer 30 , a first electrode 40 , a light emitting layer 50 , a second electrode 60 and a second insulating layer 70 . The driving layer 20 includes a gate electrode 21 , a gate insulating layer 22 , a semiconductor layer 23 , an interlayer insulating layer 24 and a wiring pattern 25 . The organic light emitting display 10 is a top emission display device, that is, light is emitted from the second electrode 60 . The first electrode 40 is electrically connected to the lead pattern 25 through a through hole provided on the first insulating layer 30 . An opening is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com