Synchronization system and method for changing a gear

A synchronizer and synchronizing ring technology, applied in clutches, components with teeth, mechanical drive clutches, etc., can solve problems such as increased force consumption, and achieve the effect of improving synchronizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

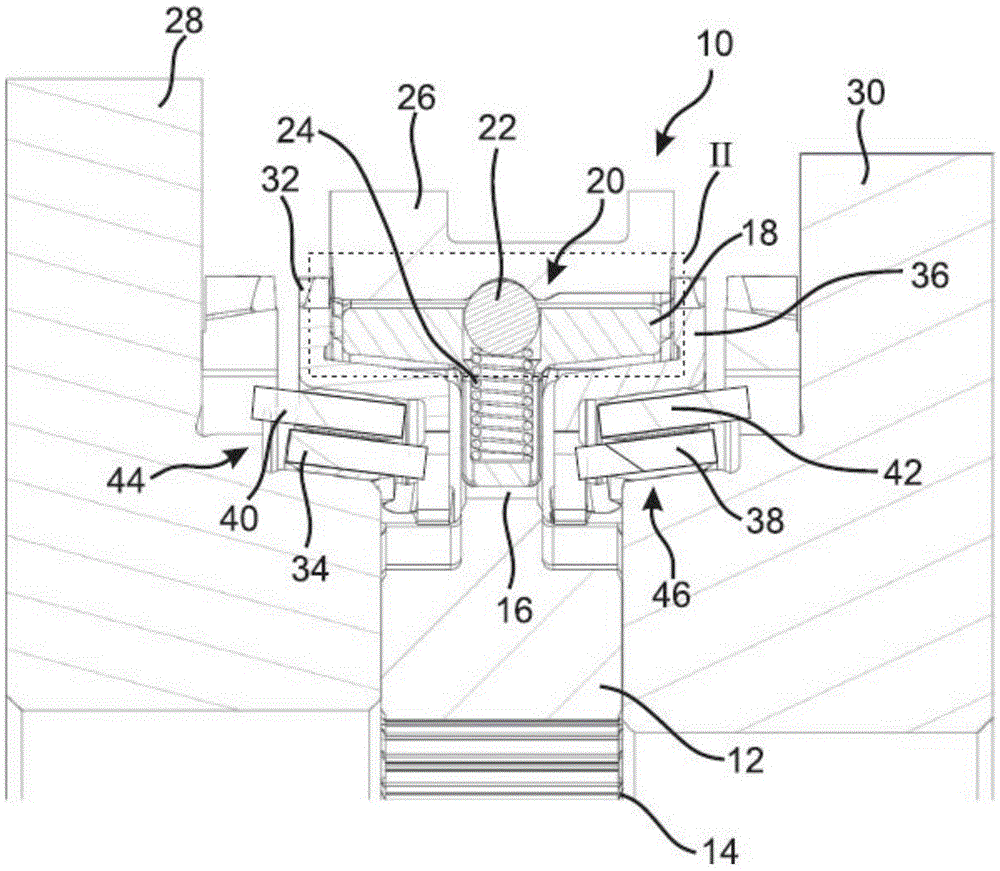

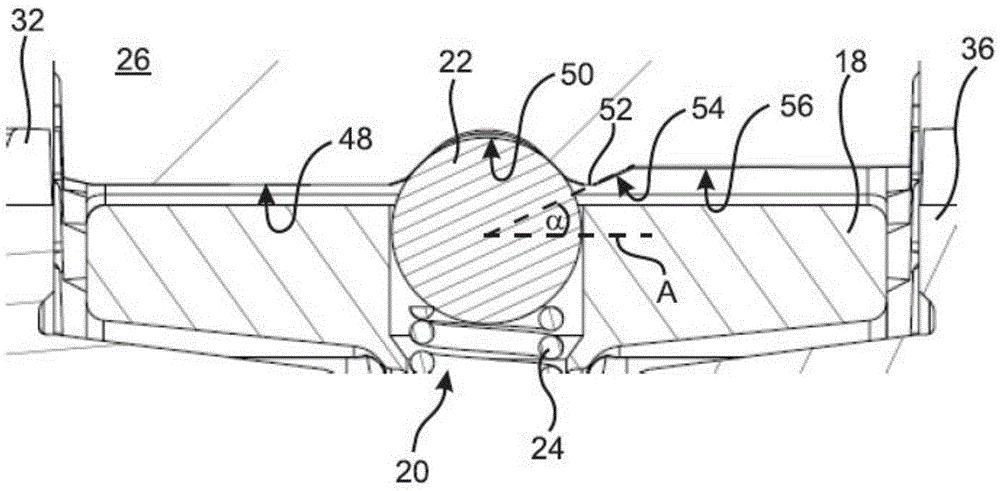

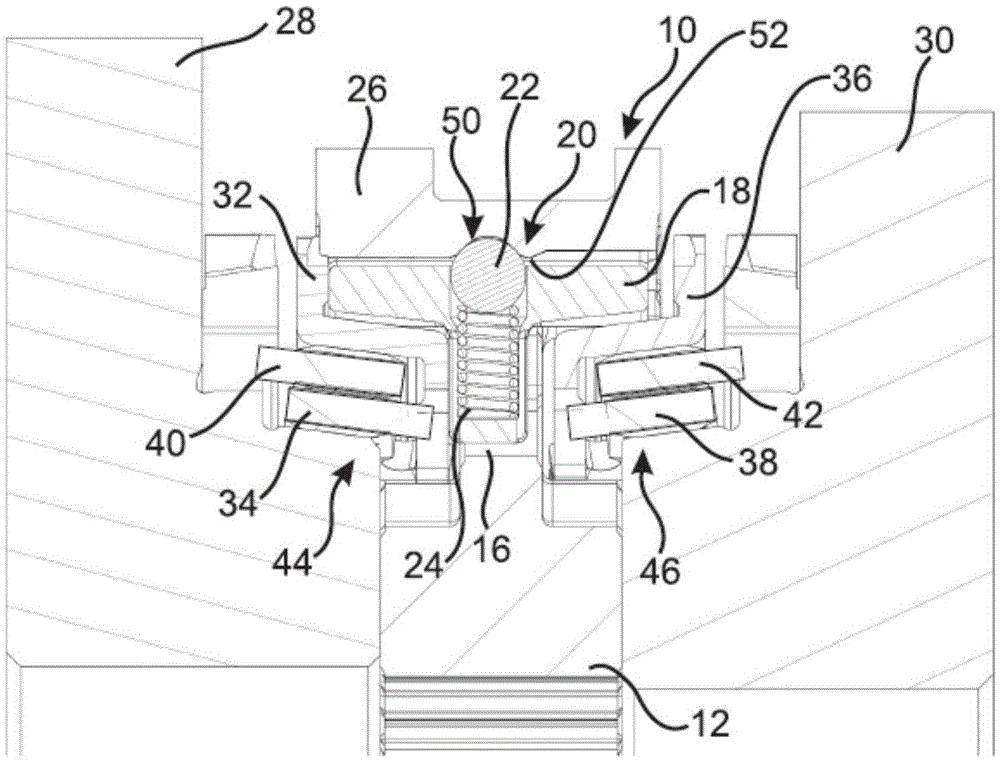

[0033] figure 1 A synchronizer 10 is shown which has a synchronizer body 12 which is arranged in a rotationally fixed manner via a toothing 14 on a drive shaft (not shown here). The drive shaft rotates about an axis that is at figure 1 The center is located horizontally within the toothing 14 .

[0034] The synchronizer body 12 has a hub portion 16 in which a pressure piece 18 is adjustably arranged. The pressure piece 18 is associated with an adjustment piece 20 which, in the embodiment shown, is formed by a ball 22 and a spring 24 . Here, the spring 24 is supported on the pressure piece 18 and presses the ball 22 in the direction of the sliding sleeve 26 , ie radially outward.

[0035] The sliding sleeve 26 is connected to the synchronizer body 12 in a rotationally fixed manner, and can slide axially in opposite directions, thereby coupling the synchronizer body 12 with the first transmission gear 28 or the second transmission gear 30, whereby the torque can be transferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com