Patents

Literature

57results about How to "Speed synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

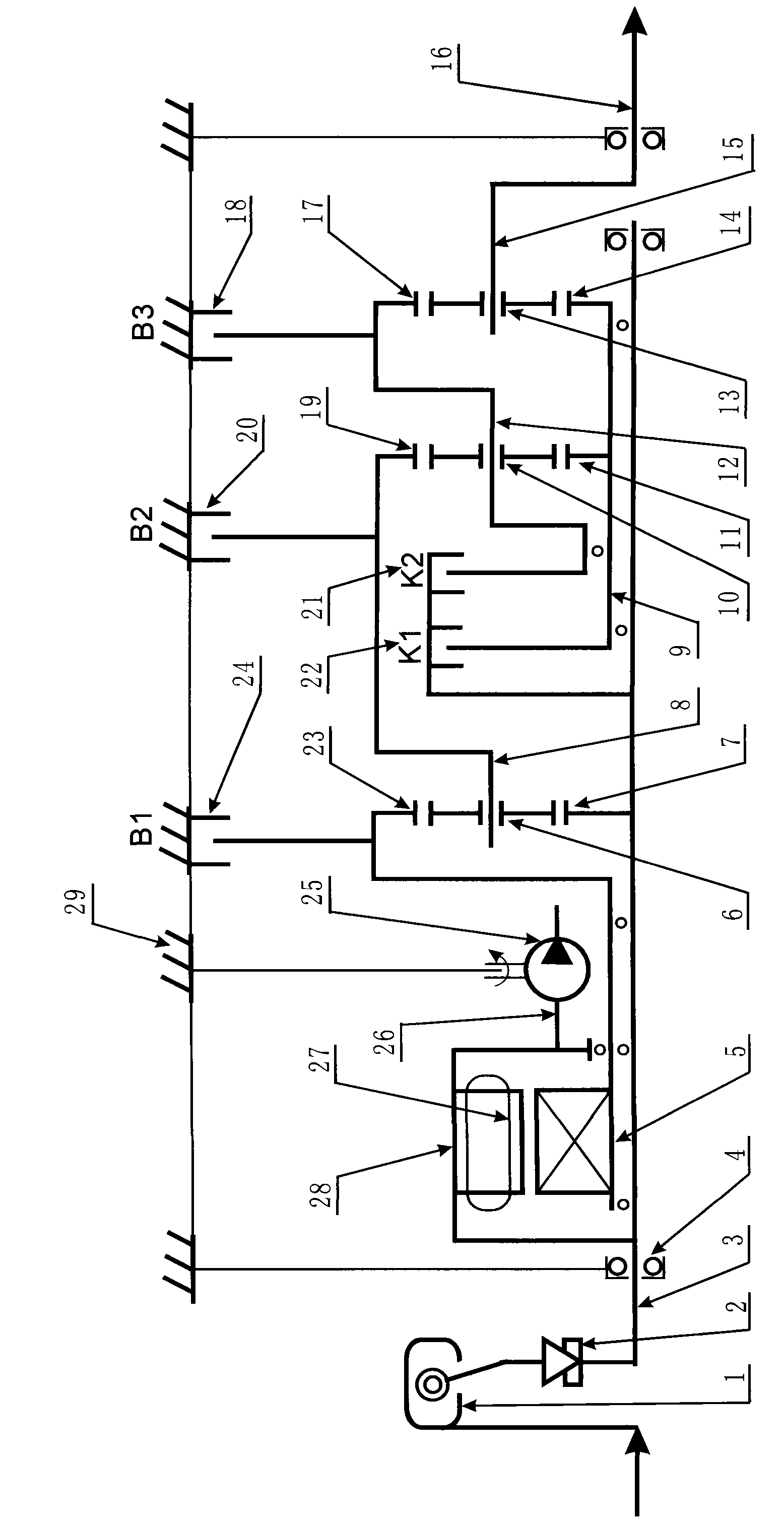

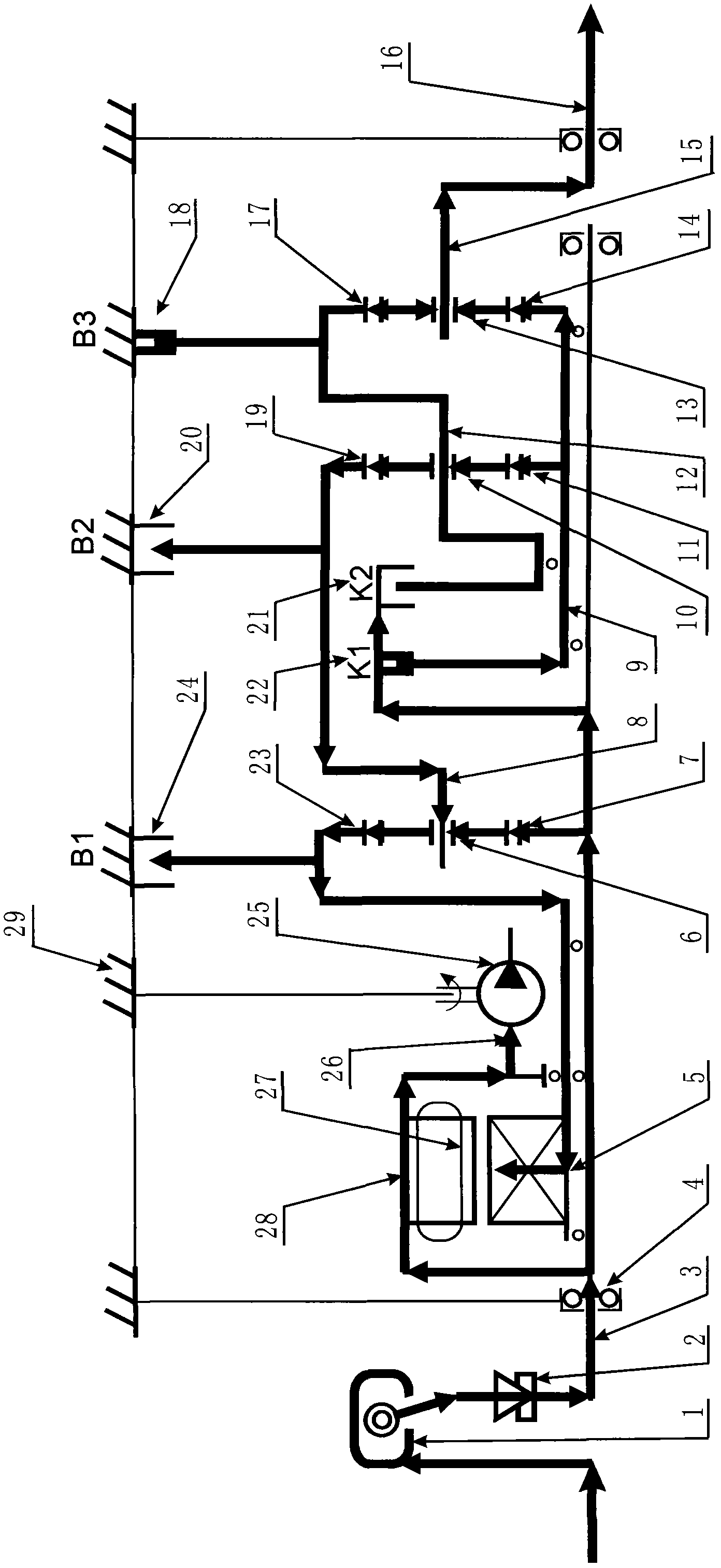

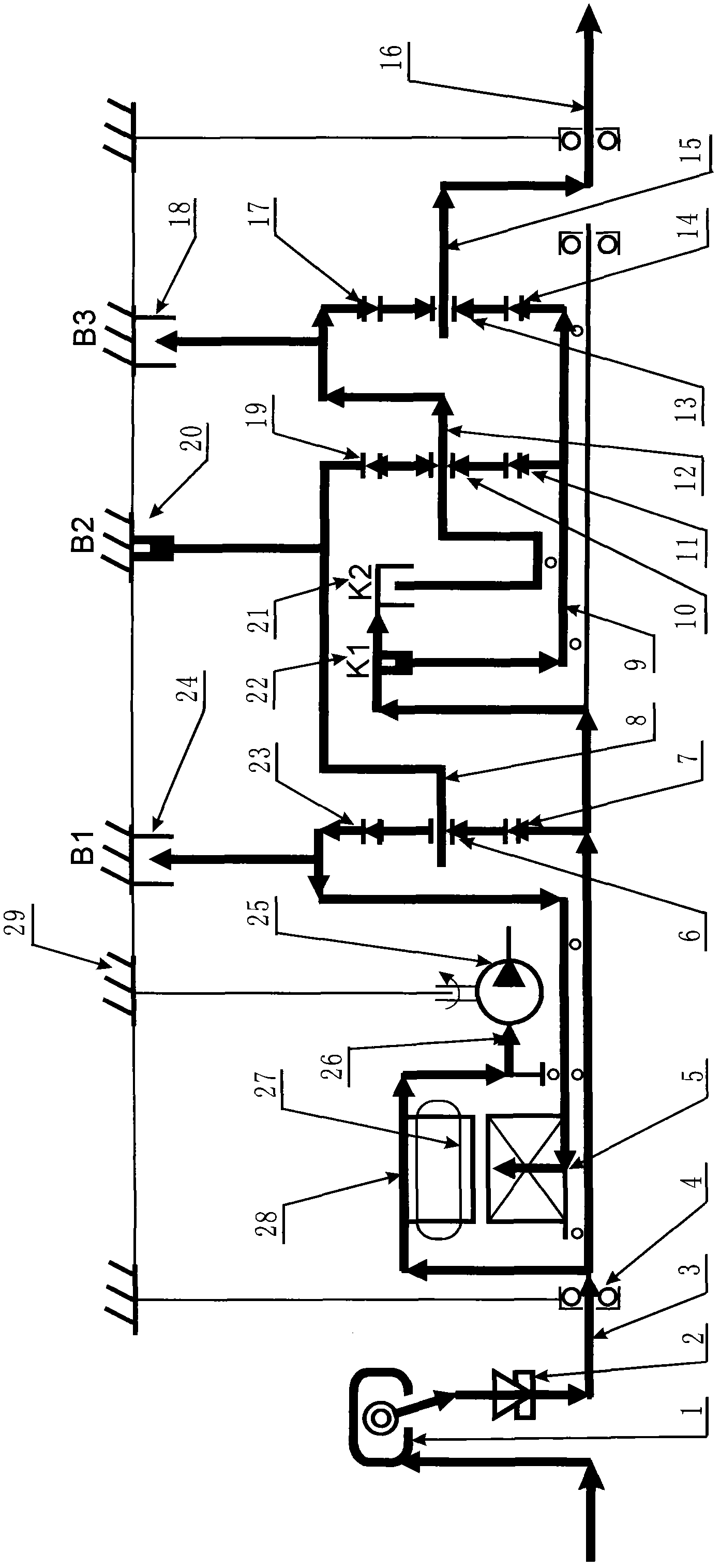

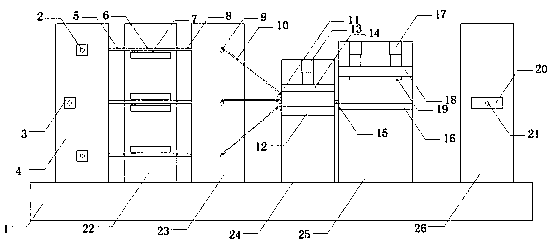

Electromechanical hybrid power mobile automatic transmission drive system

ActiveCN102069703ACompact structureReduce manufacturing costGas pressure propulsion mountingToothed gearingsElectricitySystems design

An electromechanical hybrid power mobile automatic transmission drive system is designed as an integral, which only comprises 29 main parts and can generate 6 forward gears and 1 reverse gear. Since a motor is arranged on an input shaft integrally, the whole motor has a synchronous speed with the input shaft. The motor has the functions of a generator and can drive a vehicle to travel by utilizing counterforce generated by the generator field, so as to generate electricity when an automobile travels, the automobile engine power is not additionally consumed due to the load of the generator when electricity is generated while the automobile travels, thereby reaching the energy-saving purpose. When a hybrid power driving pattern is used, a clutch and a brake are not required for gear changing during the vehicle is started or driven, thus realizing stepless speed changing and large torque transmission.

Owner:GUANGZHOU HUADU WORLDWIDE AUTOMATIC TRANSMISSION

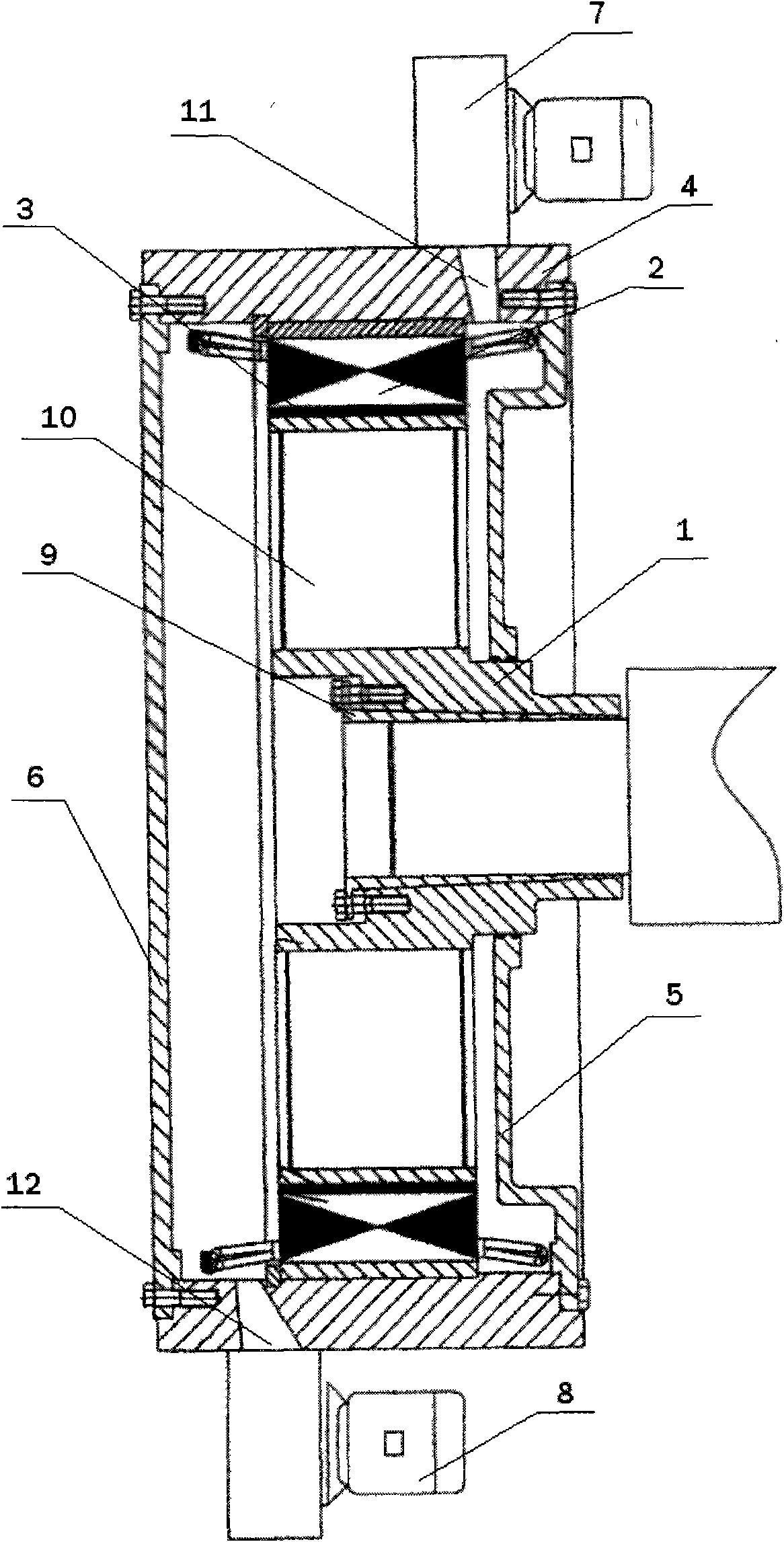

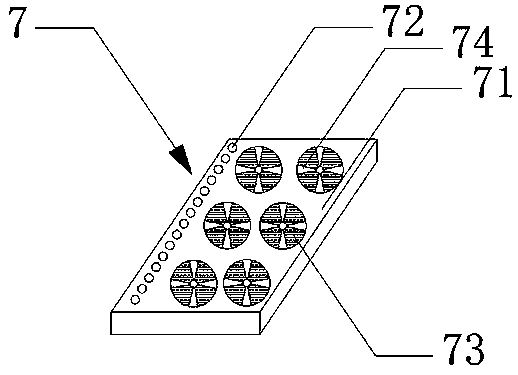

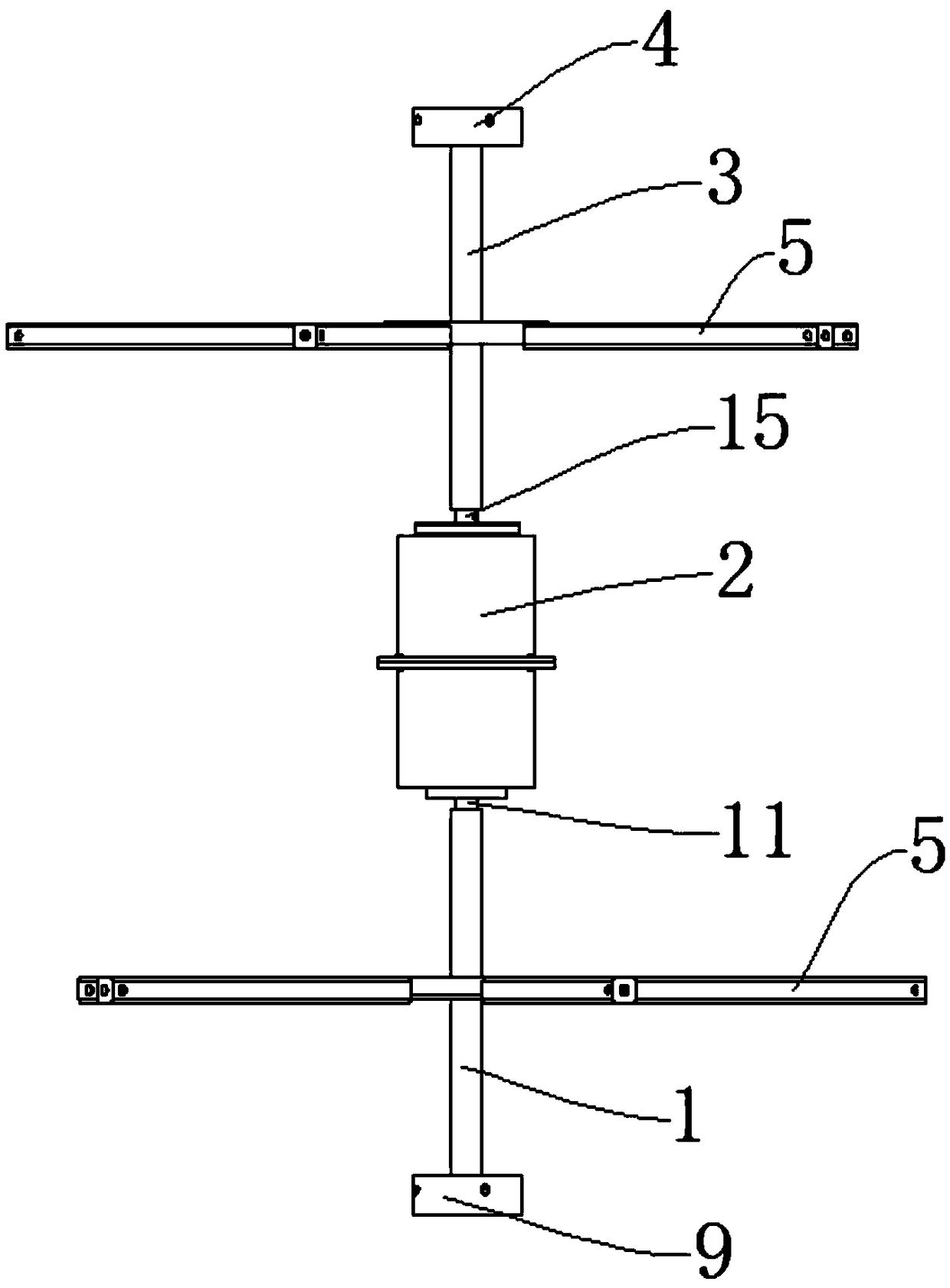

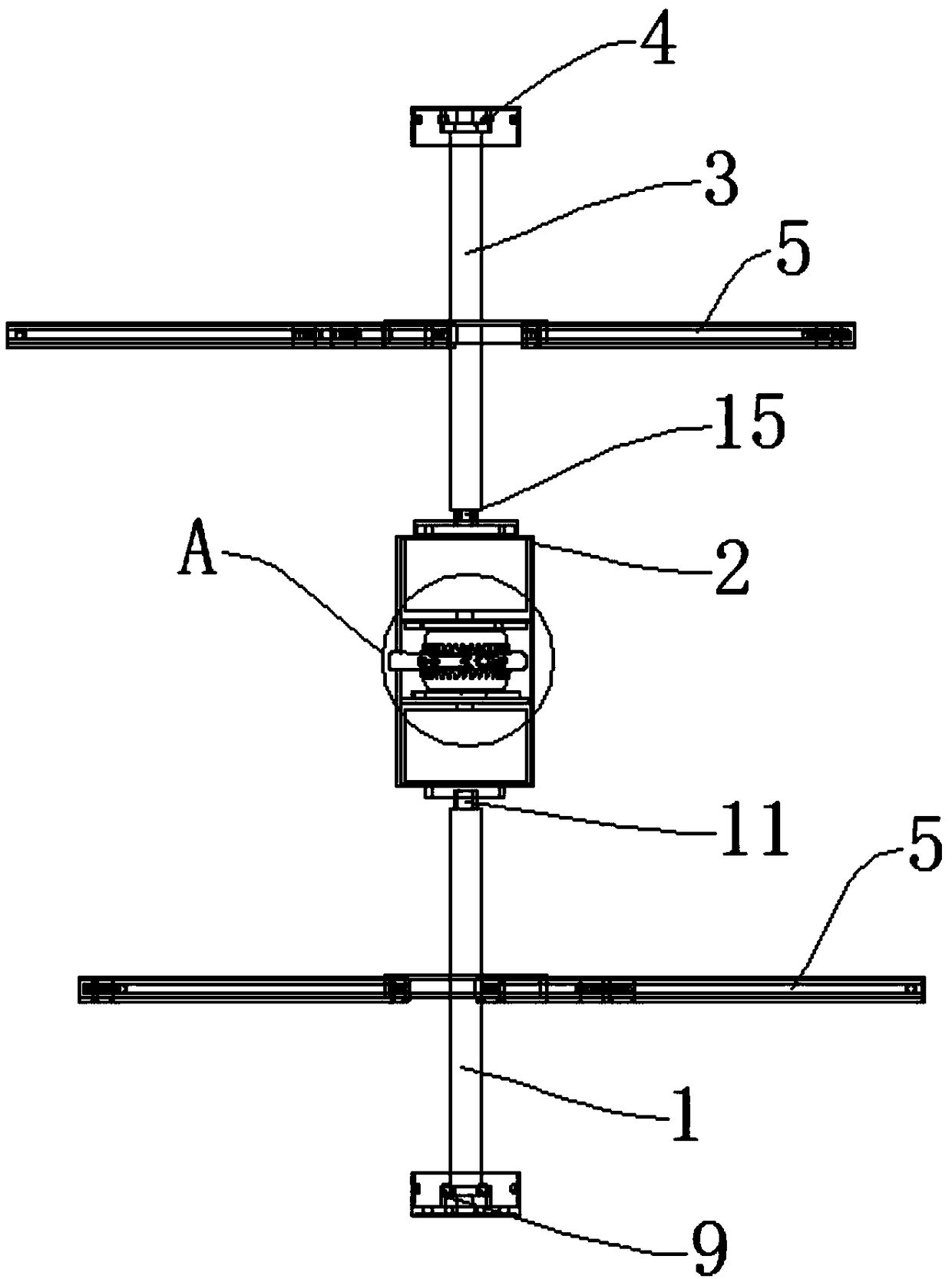

Non-axis motor

InactiveCN102055277ASimple structureExtended service lifeCooling/ventillation arrangementSupports/enclosures/casingsAir blowerOperating temperature

The invention relates to a motor, in particular to a non-axis motor which is combined with a slurry pump. The non-axis motor comprises a rotor, a stator, a permanent magnet and an enclosure, and is characterized in that the rotor is internally provided with an installation cavity and externally provided with a rotor auxiliary iron, permanent magnetic blocks, the stator and the enclosure in sequence; the permanent magnetic blocks are distributed on the outer end of the rotor auxiliary iron; two opposite positions on the enclosure are respectively provided with a through hole; and one through hole is communicated with an air blower, and the other through hole is communicated with an induced-draught fan. The non-axis motor has the advantages that the motor can be directly installed on a driven device, thus reducing manufacturing cost; the devices can realize synchronous revolving speed and balanced rotation; the structure layout is compact, thereby decreasing the occupied area; the circulating air radiation is adopted, thus ensuring reasonable control of operating temperature, and having good heat dissipation effect; and the motor operation is safe and stable, and saves electric energy.

Owner:DALIAN YULIN ELECTRIC MOTOR

Fiber stretching device

The invention discloses a fiber stretching device. The device comprises an oven, a heater arranged in the oven, a guide roll, a fiber stretching roll group and a drive unit which is arranged outside the oven and is used for driving the fiber stretching roll group, wherein, the oven is equipped with a fiber bundle inlet and a fiber outlet; the guide roll is arranged at the inner side of the fiber bundle inlet; the fiber stretching roll group is arranged at the inner side of the fiber outlet and comprises drive fiber stretching rolls and driven fiber stretching rolls; the surface of each drive fiber stretching roll is equipped with a circular arc projecting surface; and the driven fiber stretching rolls with smooth surfaces are in a cylindrical shape and are arranged below the drive fiber stretching rolls. By utilizing the fiber stretching device, a glass fiber bundle can be stretched into monofilament fiber with certain width so as to facilitate the impregnation of resin during melt impregnation process.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

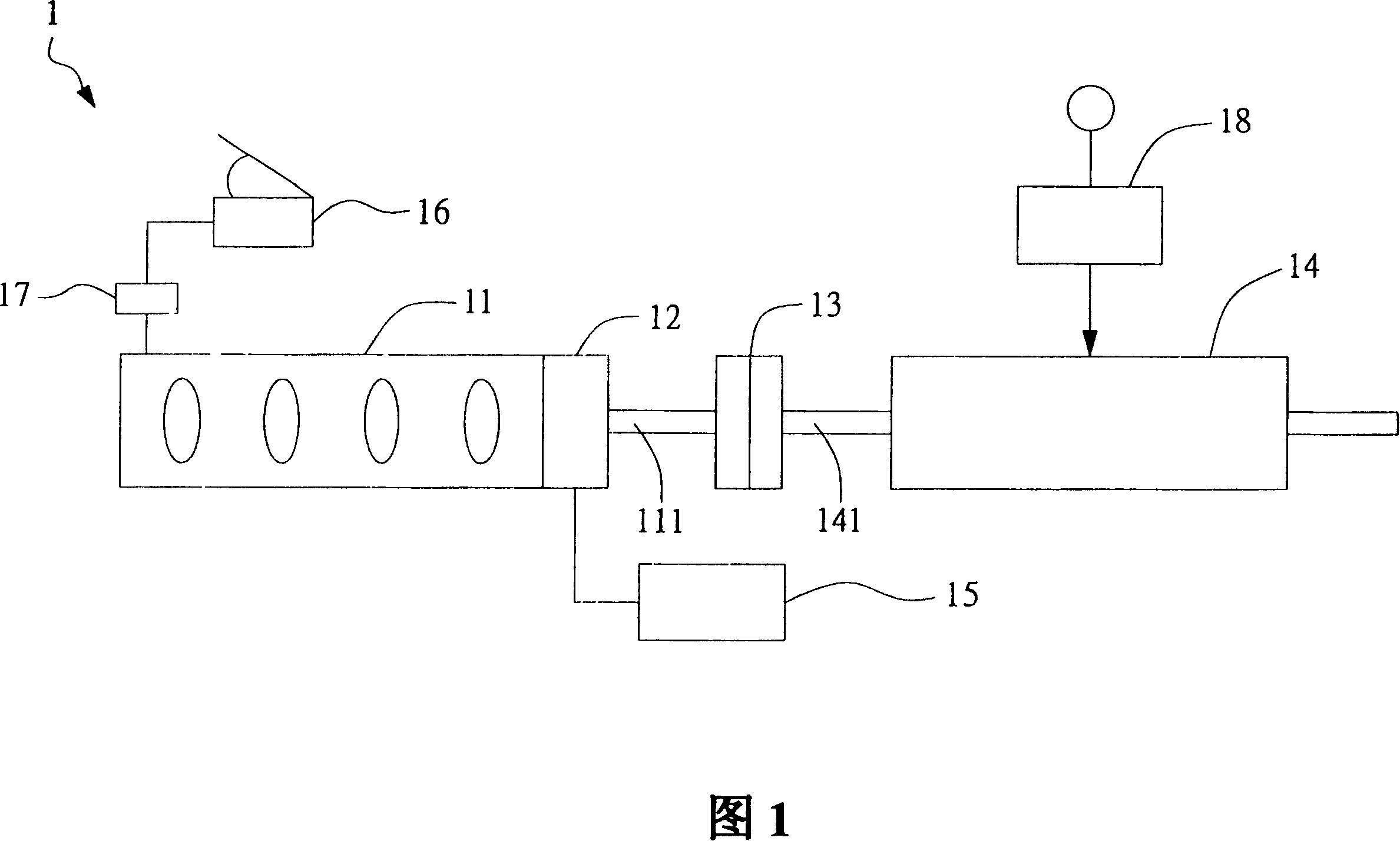

Engine intelligent idling control system and method

ActiveCN108944933ASolve the forward sliding of coasting brakeSpeed synchronizationDriver input parametersVariatorEngineering

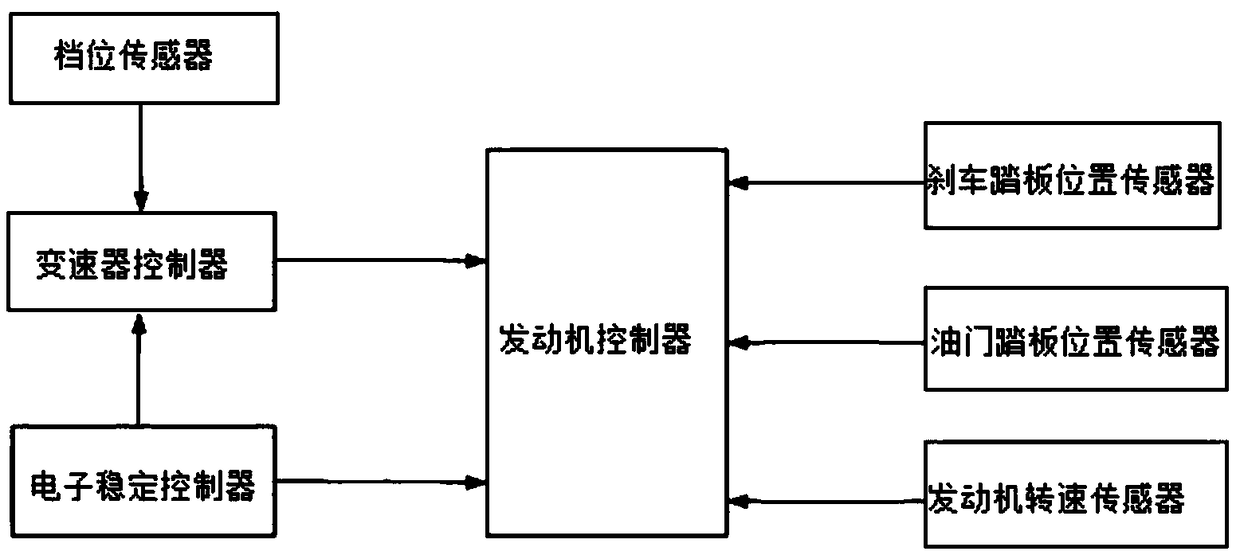

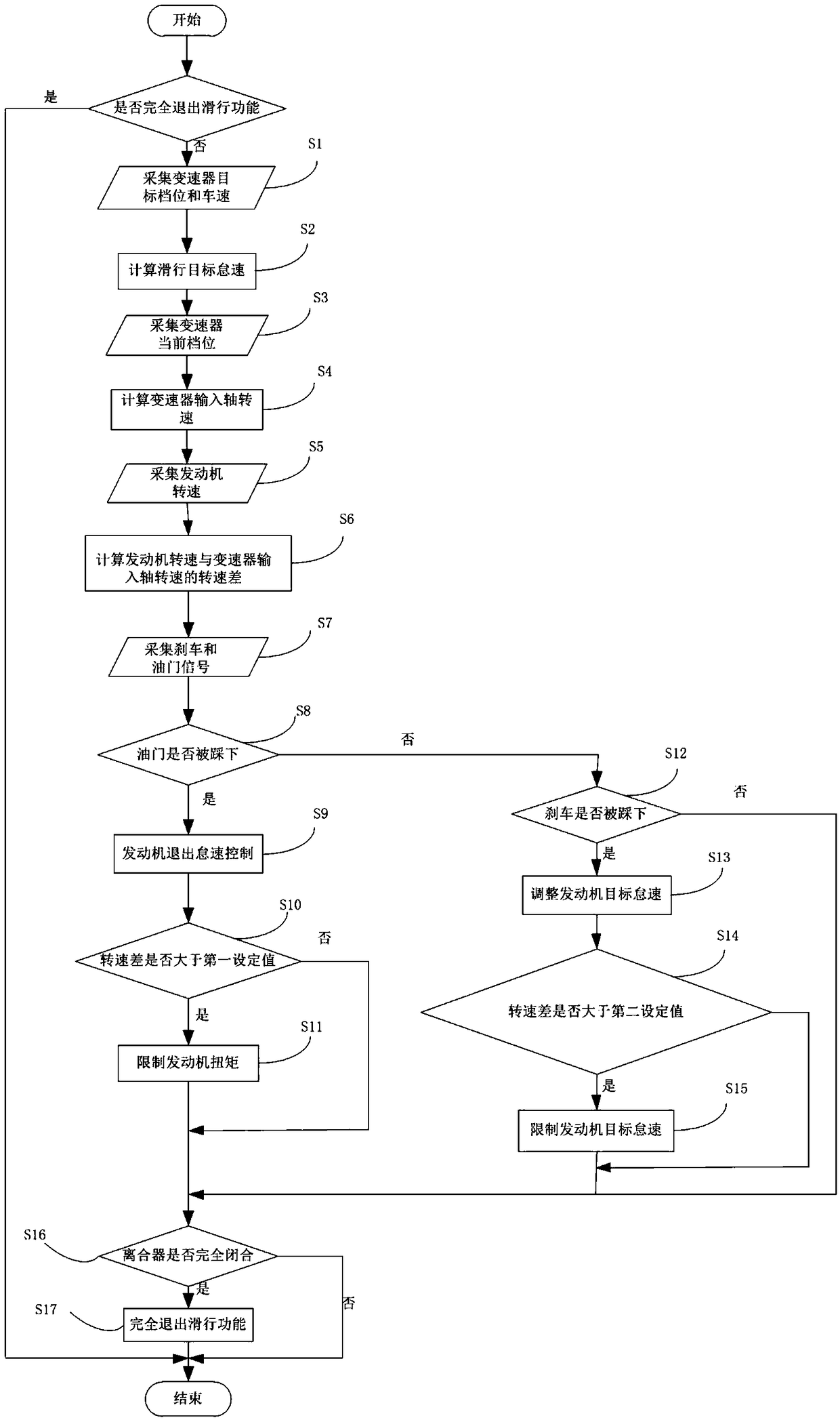

The invention provides an engine intelligent idling control system and method. The system comprises an engine rotation speed sensor, an accelerator pedal position sensor, a brake pedal position sensor, a gear sensor, a wheel speed sensor, an electronic stabilization controller, a transmission controller and an engine controller. The engine rotation speed sensor is used for acquiring the current rotation speed of an engine. The electronic stabilization controller is used for calculating the real-time vehicle speed according to the wheel speed. The transmission controller is used for calculatingthe current rotation speed of a transmission according to the current gear and the real-time vehicle speed. The engine controller is used for judging the rotation speed difference between the currentrotation speed of the engine and the current rotation speed of the transmission when a vehicle is in a sliding mode and controlling the actual output rotation speed of the engine according to the rotation speed difference. It can be guaranteed that under a sliding working condition, the rotation speeds of input shafts of the engine and the transmission are synchronous.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

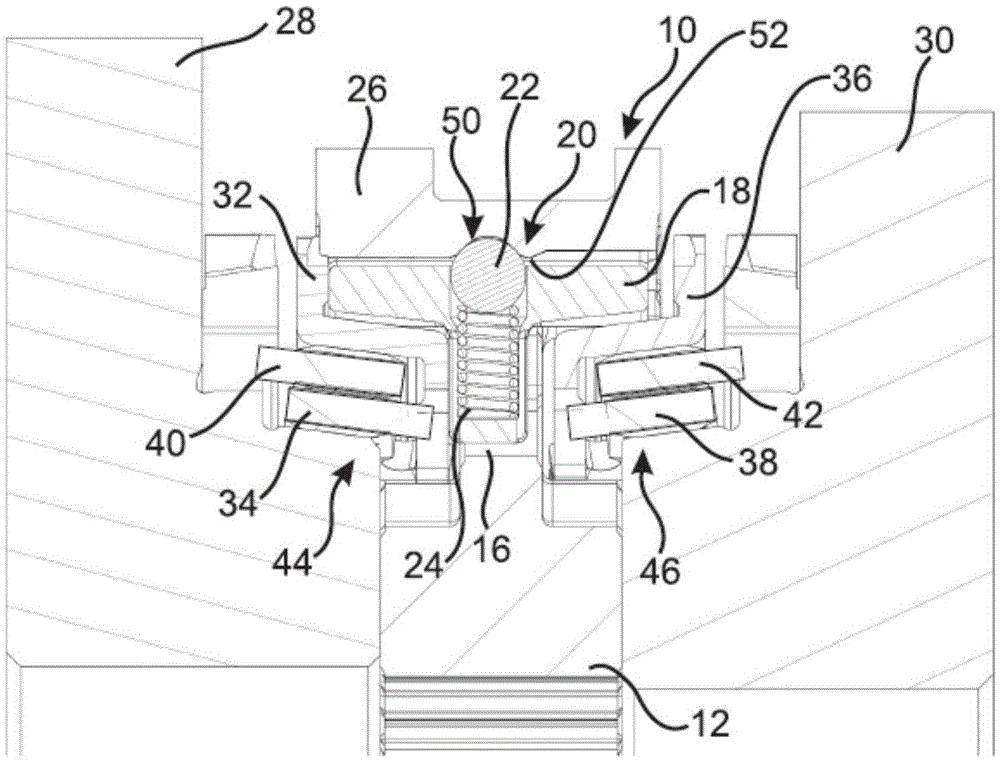

Synchronization system and method for changing a gear

ActiveCN105556151AFriction does not appearImprove synchronicityMechanical actuated clutchesGearing controlGear wheelSynchronization system

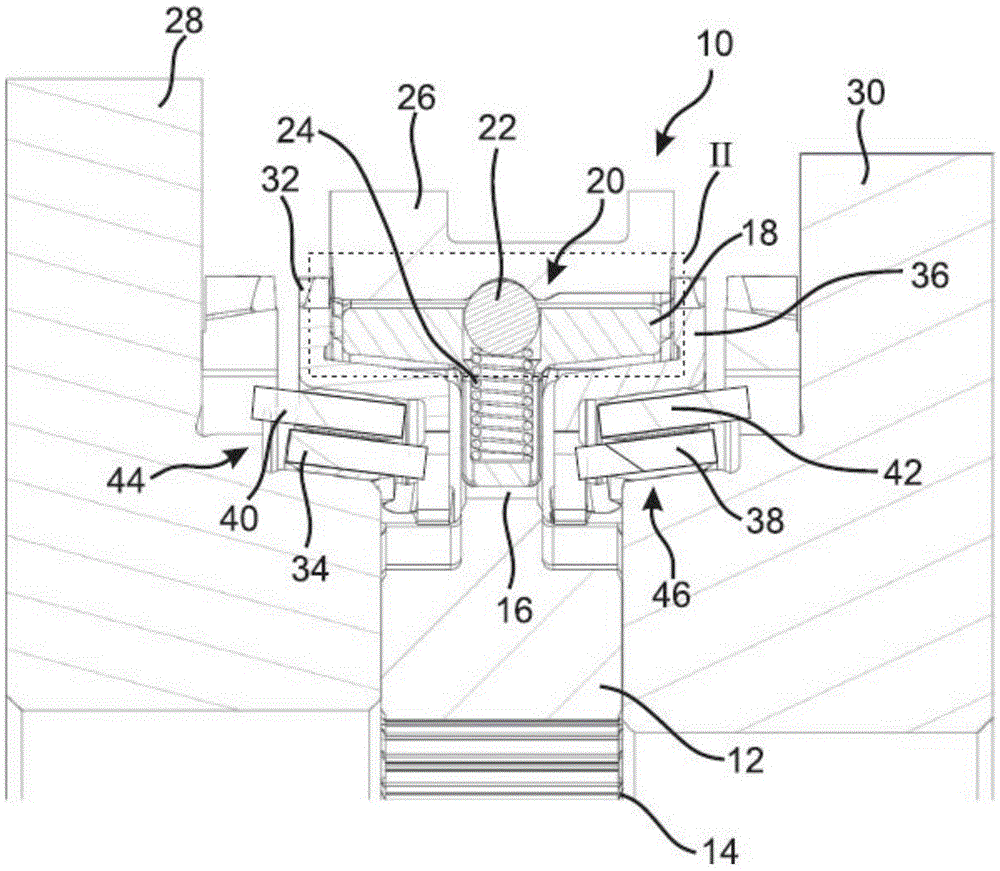

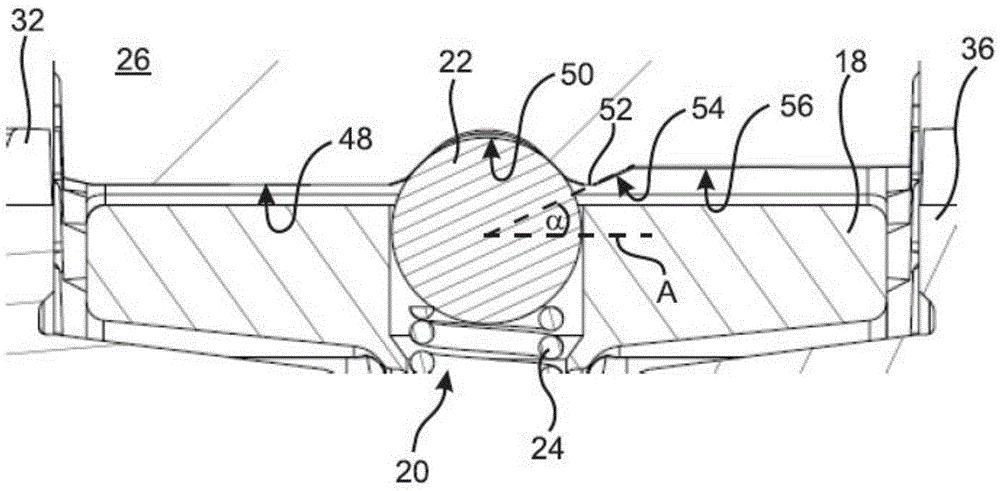

The invention provides a synchronization system and method for changing a gear. The invention relates to a synchronization system (10) for a change-speed gearbox comprising a synchronizing body (12) which is assigned to a gearbox shaft, and comprising a first and a second synchronizing ring (32, 34, 36, 38), which are assigned to a first and a second gear wheel (28, 30) respectively. Furthermore, the synchronizing ring (10) has a sliding sleeve (26) and at least one pressure piece (18), which is displaceably arranged on the synchronizing body (12) and is able to exert an axial compressive force on the corresponding synchronizing ring (32, 34, 36, 38). Moreover, the synchronizing ring (10) has a resilient actuating element (20), which acts between the sliding sleeve (26) and the pressure piece (18), a latching recess (50) for the neutral position and a ventilation contour (54) being provided on the sliding sleeve (26). The ventilation contour (54) can interact with the actuating element (20) in such a way that, when the sliding sleeve (26) is moved in order to engage with one of the gear wheels (28, 13), the pressure piece (18) is loaded away from the corresponding synchronizing ring (32, 34, 36, 38). The ventilation contour (54) has an axial length which is no more than twice the idle stroke of the sliding sleeve (26) between the neutral position and the position in which the corresponding synchronizing ring (32, 34, 36, 38) presses against a frictional surface assigned thereto.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

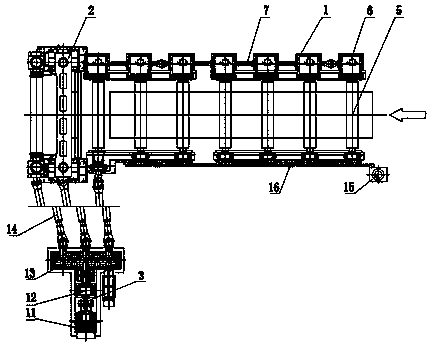

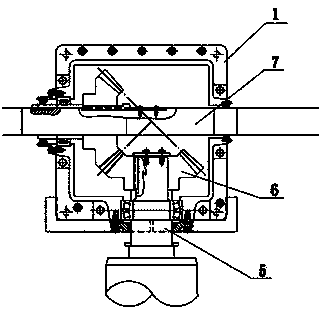

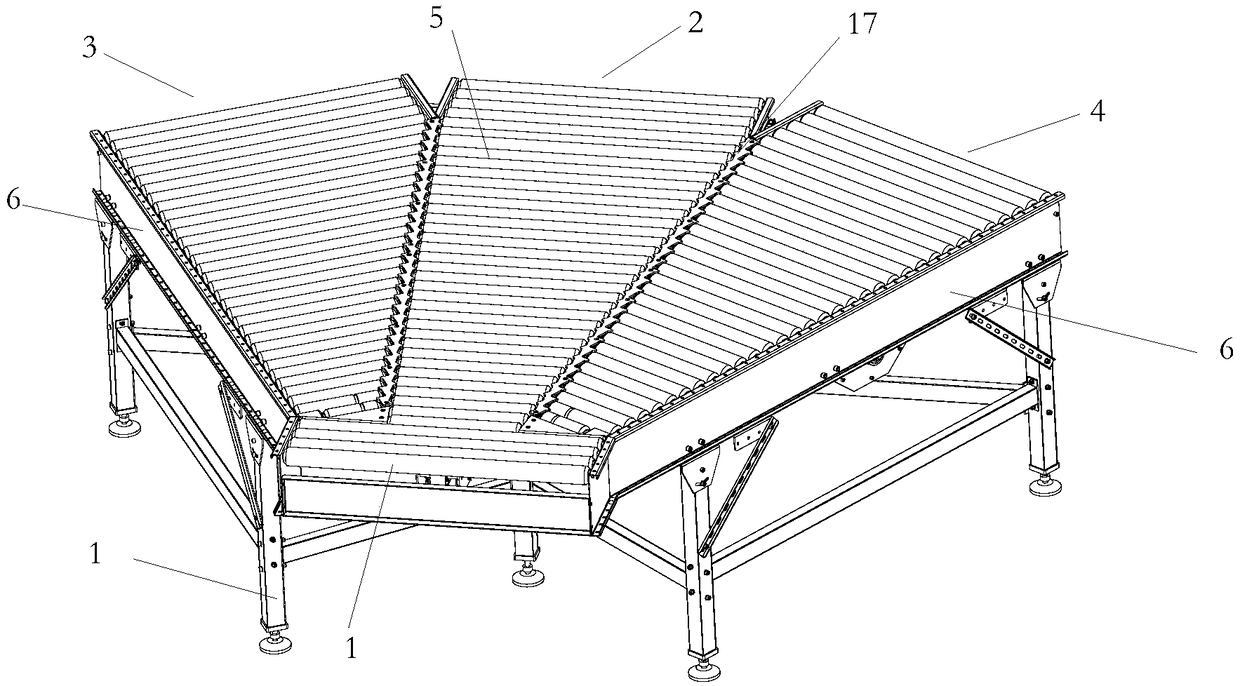

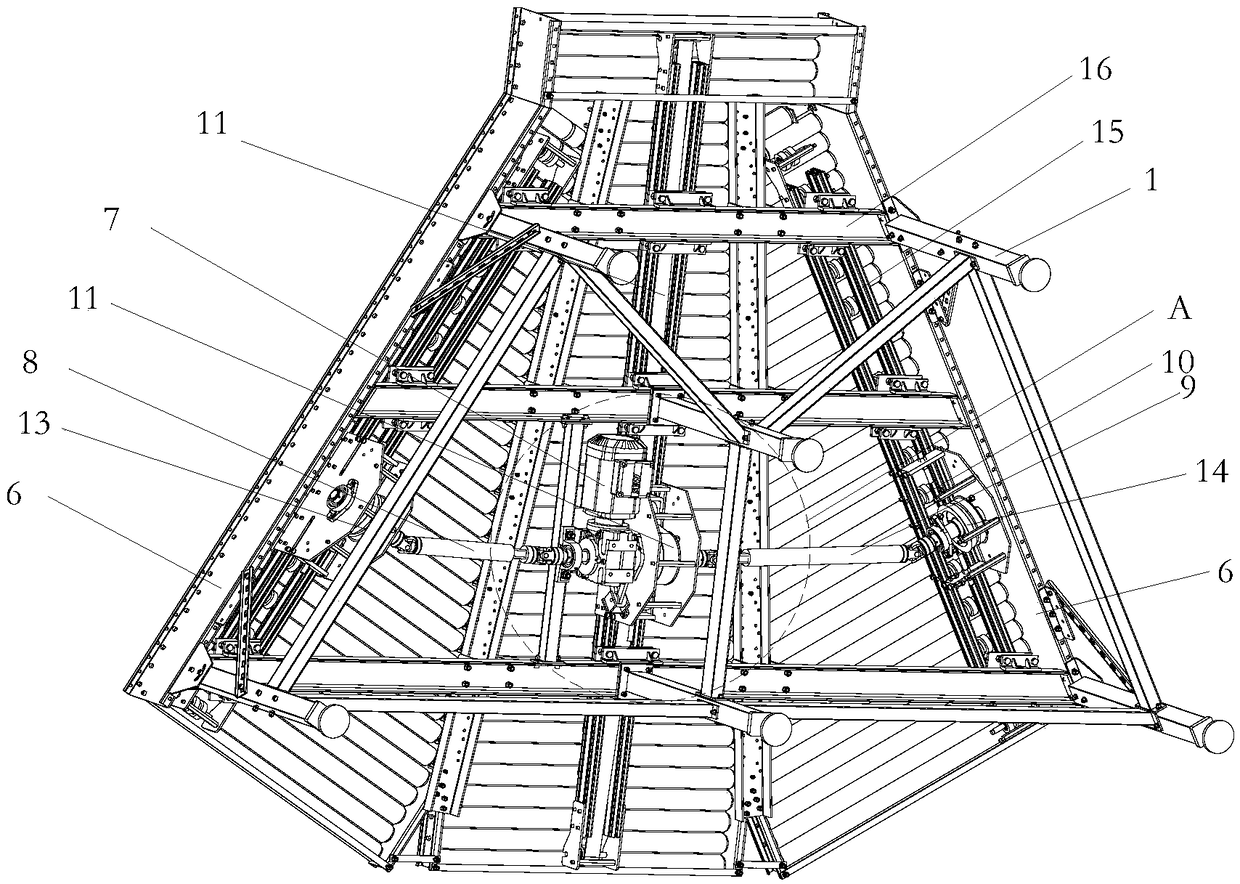

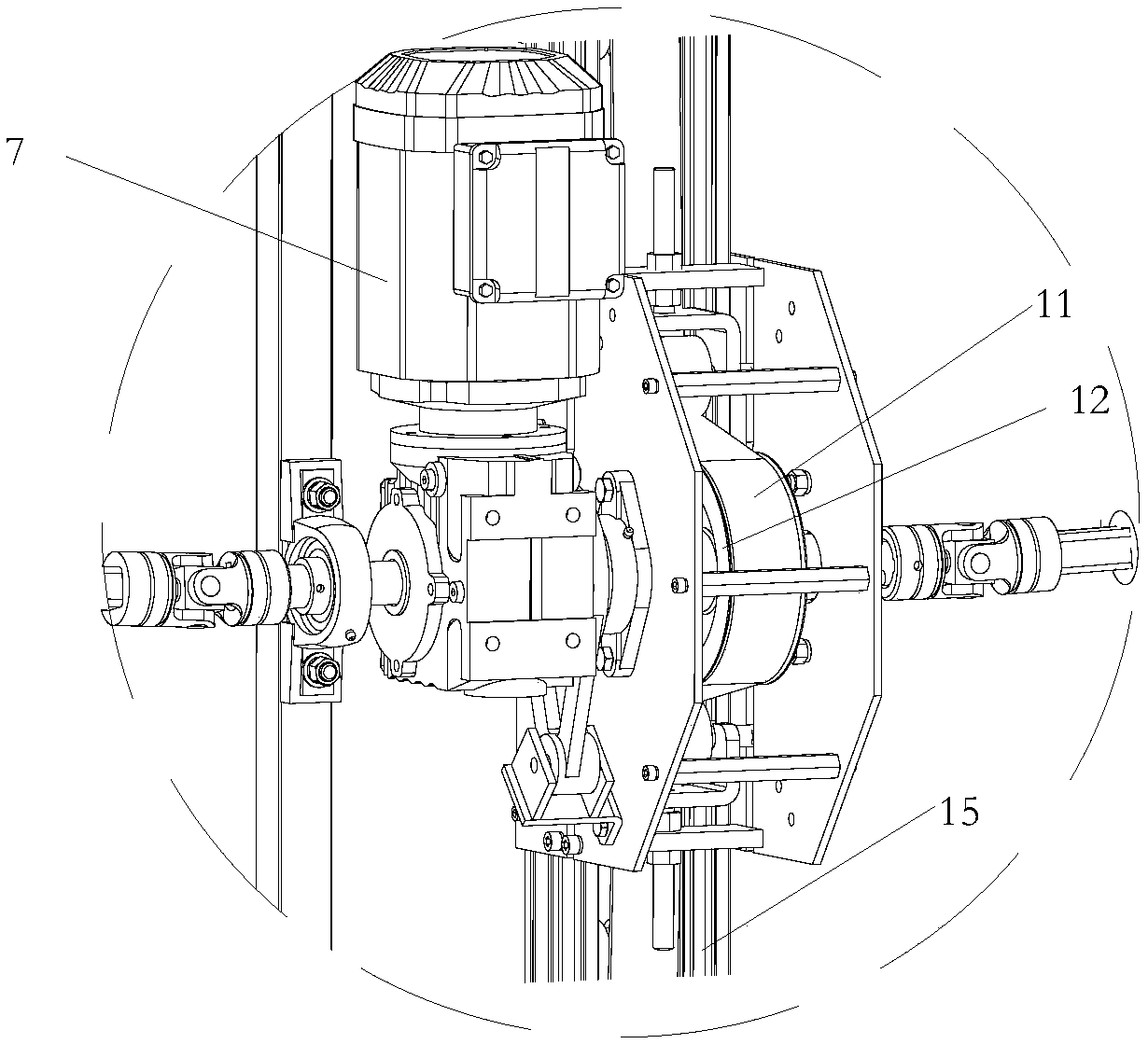

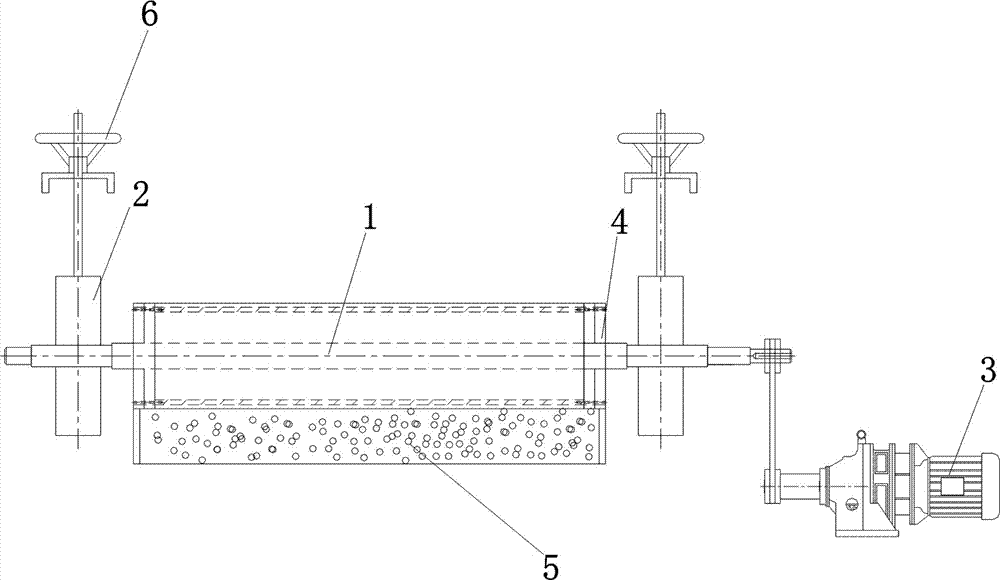

Constant-speed synchronous conveying device for slabs

ActiveCN104190889AAvoid the phenomenon that the transmission cannot be strictly in accordance with the design speedConsistent flame cleaning depthSlab casterGear wheel

The invention relates to a constant-speed synchronous conveying device for slabs. The constant-speed synchronous conveying device for the slabs comprises a concentrated roller bed and a transmission device. The concentrated roller bed comprises a bottom frame, a plurality of roller assemblies and a synchronizing shaft located on the same side of all the roller assemblies. Each roller assembly comprises a roller, a bearing seat and a bearing. The constant-speed synchronous conveying device for the slabs further comprises bevel gear pairs, wherein the number of the bevel gear pair is equal to that of the roller assemblies. Each bevel gear pair comprises a first bevel gear and a second bevel gear. The synchronous shaft is in key joint with all the first bevel gears. Each roller is in key joint with the corresponding bevel gear. The speed ratio of each bevel gear pair is 1:1. One roller assembly is a driving roller assembly. The transmission device is connected with the driving roller assembly. By the adoption of the constant-speed synchronous conveying device for the slabs, the special use requirements of a clearing system in a slab caster are met, the rotation speeds of all the rollers are identical through the concentrated roller bed and the transmission device, the speeds of the slabs to pass through a scarfing machine are identical, so that the scarfing depths of the slabs are identical, and the quality of the slabs can be improved.

Owner:WISDRI ENG & RES INC LTD

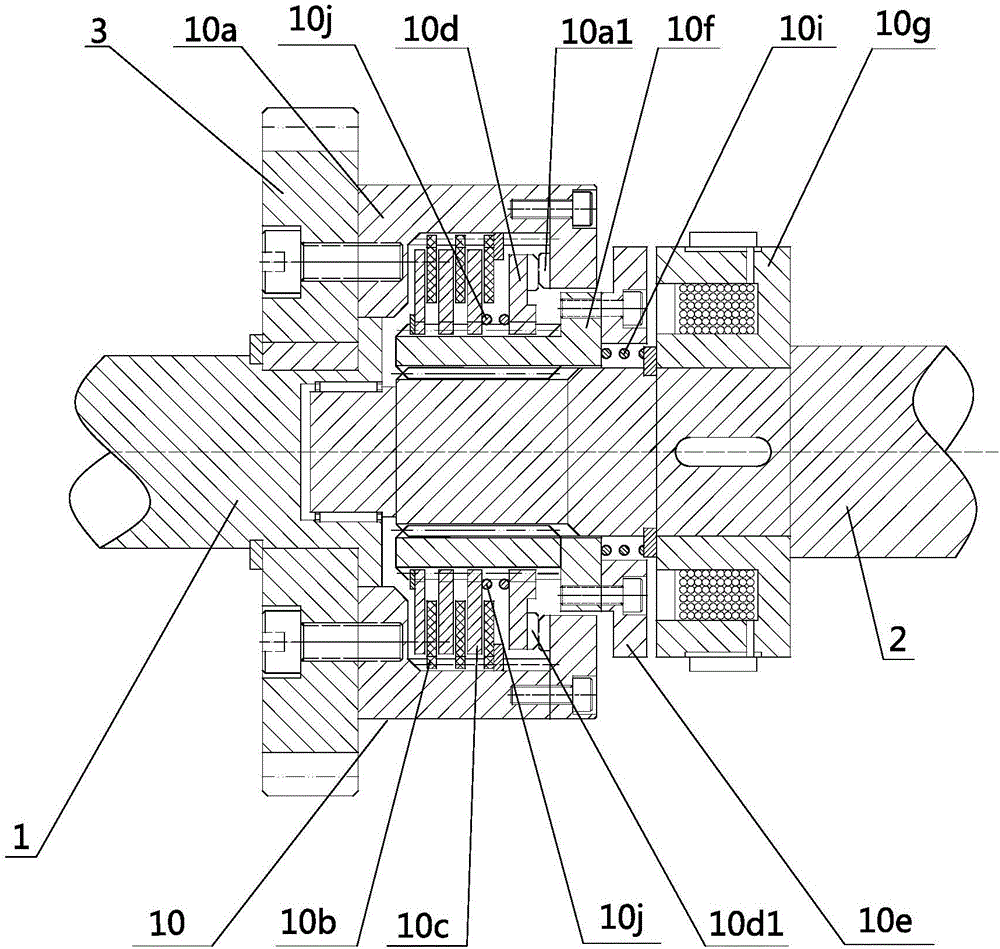

Electromagnetic clutch with wire-driven friction and meshing transmission joint device

ActiveCN106594106ASimple structureReduce volumeMechanical actuated clutchesMagnetically actuated clutchesElectromagnetic clutchCoupling

The invention discloses an electromagnetic clutch with a wire-driven friction and meshing transmission joint device. When a solenoid coil is not electrified, under the action of a return spring, an internal splined hub with lateral teeth and a spline coupling with lateral teeth are not in meshing transmission, and the clutch is in a disengaged state; and when the solenoid coil is electrified, under the action of an electromagnetic force, a spline housing overcomes the elastic force of the return spring and moves toward an electromagnet, and the internal splined hub with lateral teeth and the spline coupling with lateral teeth are in meshing transmission, so that synchronous transmission of the internal splined hub with lateral teeth and the spline housing is realized, and the clutch is engaged.

Owner:SHANDONG UNIV OF TECH

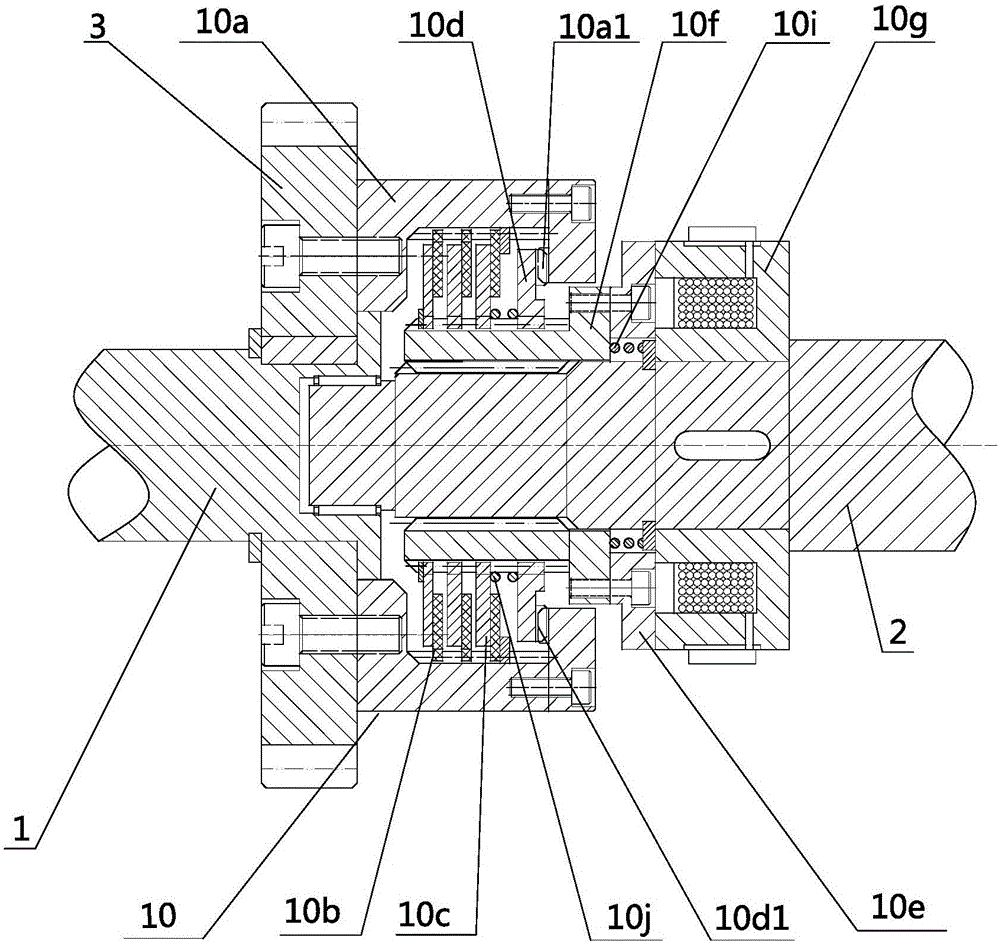

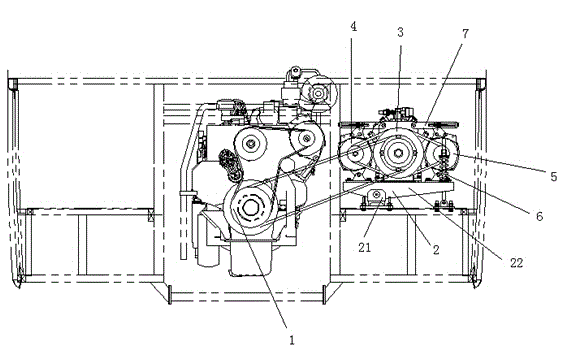

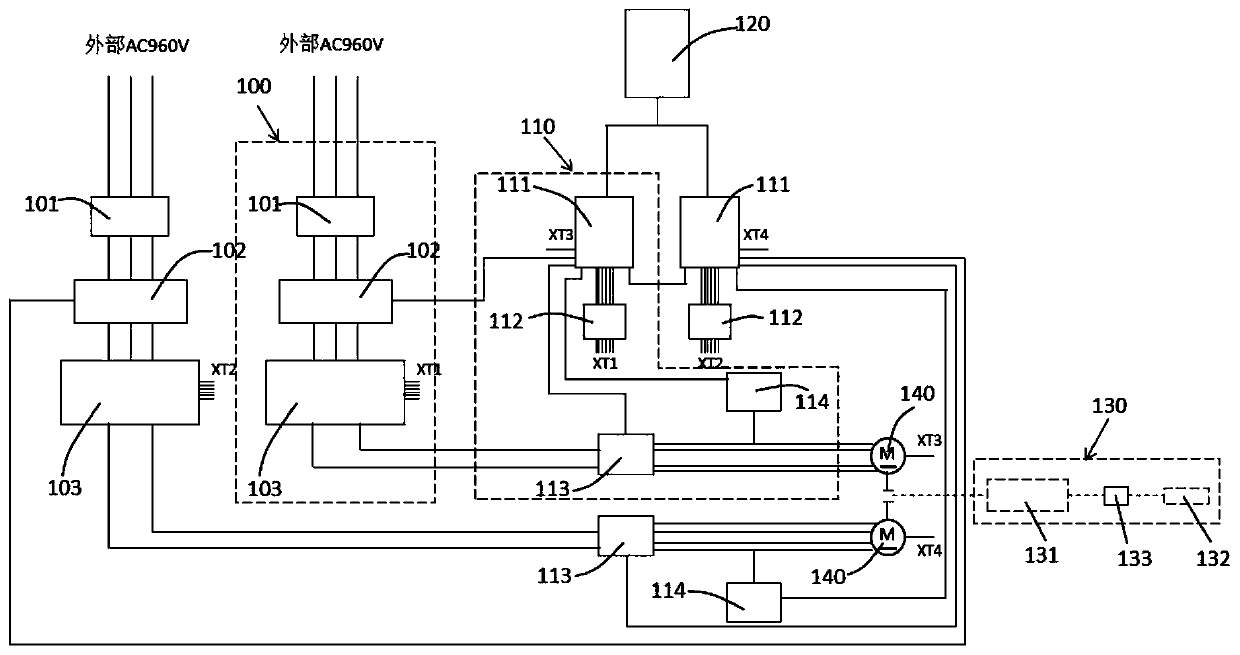

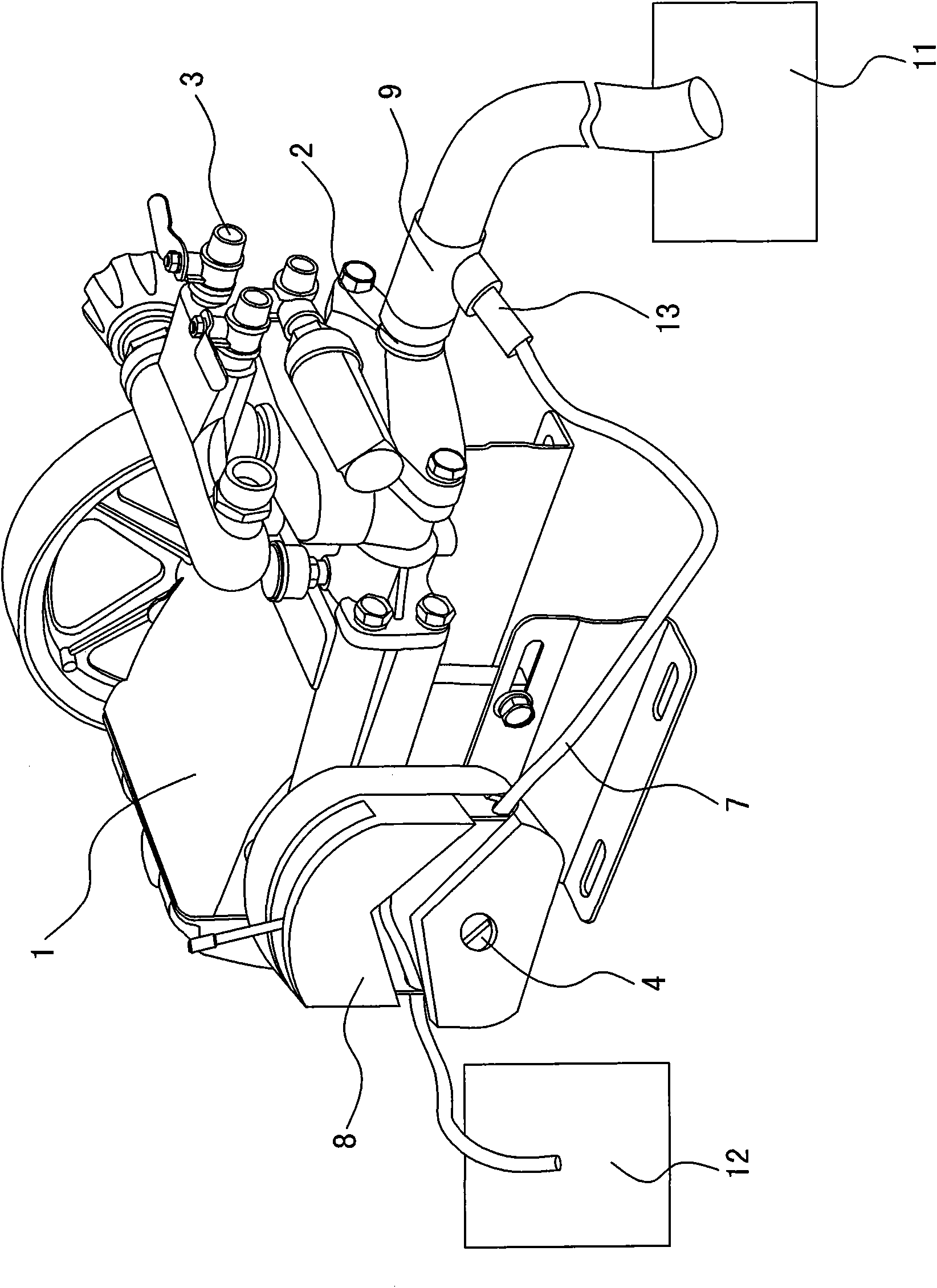

Complete coach power supply device

ActiveCN104626994AEasy to adjustGuaranteed speedGearingElectric powerGenerating capacityElectric generator

The invention discloses a complete coach power supply device which comprises an engine, a mounting support, a compressor, a first generator with a storage battery and a second generator with a storage battery. The mounting support comprises a base and a supporting frame, the base is fixed onto a coach framework, the supporting frame is rotatably connected with the base, the compressor and the first generator with the storage battery are mounted on the supporting frame, the compressor is in transmission connection with the engine through a belt, the second generator with the storage battery is mounted on the supporting frame, the first generator with the storage battery and the second generator with the storage battery are arranged on two sides of the compressor respectively, the first generator with the storage battery is in transmission connection with the second generator with the storage battery through a belt, and a vertical adjusting device for adjusting tension of the belt is mounted on the supporting frame. The complete coach power supply device is simple in structure, simple and convenient to mount, low in failure rate and cost and high in power generating capacity, and mounting spaces of the other parts of an engine bin are not occupied when the generators are mounted.

Owner:ANHUI ANKAI AUTOMOBILE

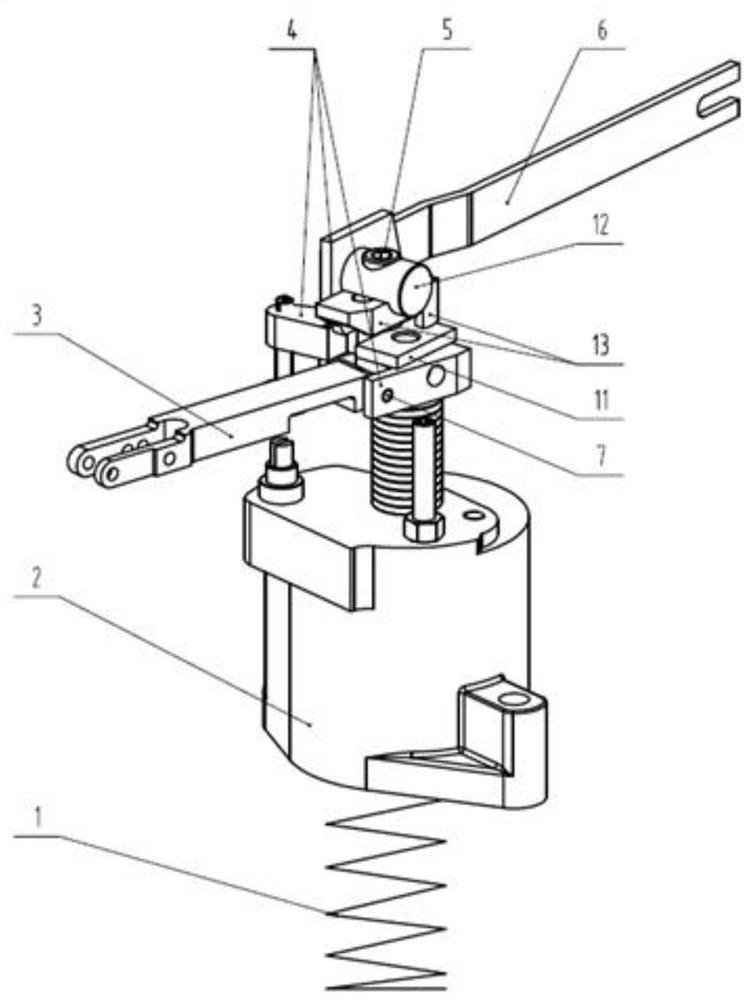

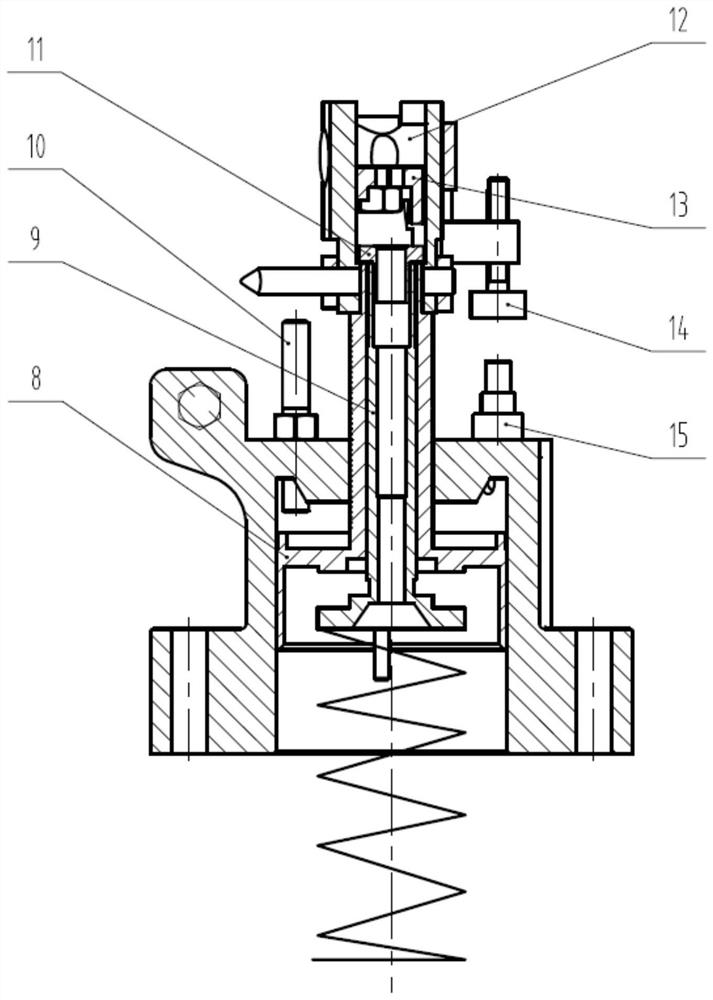

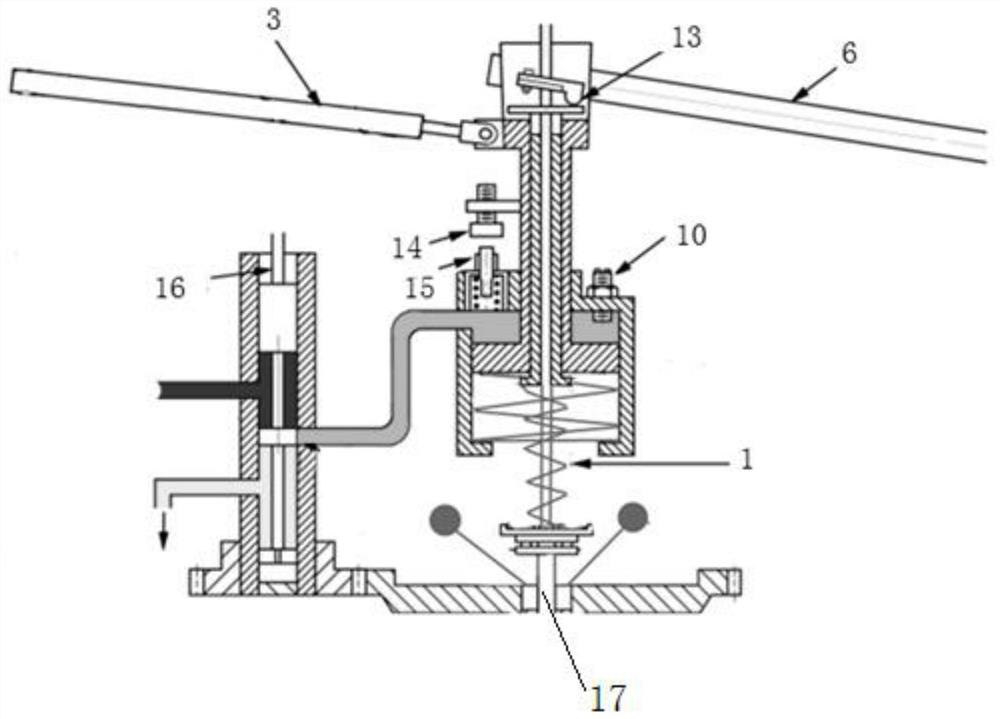

Speed regulation control device

ActiveCN113756964AGuaranteed uptimeStable speed controlFuel-injection pumpsMachines/enginesSpool valveDieseling

The invention discloses a speed regulation control device which comprises a speed regulation piston cylinder, a speed regulation piston, a speed regulation piston rod, a lever, a feedback cam, a one-way valve, a feedback seat, a feedback connecting rod and a speed regulation spring. Control oil pressure is received in the speed regulation piston cylinder to push the speed regulation piston and the speed regulation piston rod to move, the movement direction is determined by comparing the control oil pressure with spring force below the speed regulation piston cylinder, and therefore the control oil pressure is compared with the speed regulation spring to control a sliding valve to move to control the rotating speed. The feedback connecting rod is connected with the feedback cam through a first cylindrical pin, and a diesel engine can be more stable in the operation process by adjusting the feedback cam. Displacement signals can be converted into oil pressure, and then the rotating speed of the diesel engine is controlled through the oil pressure.

Owner:CHONGQING HONGJIANG MACHINERY

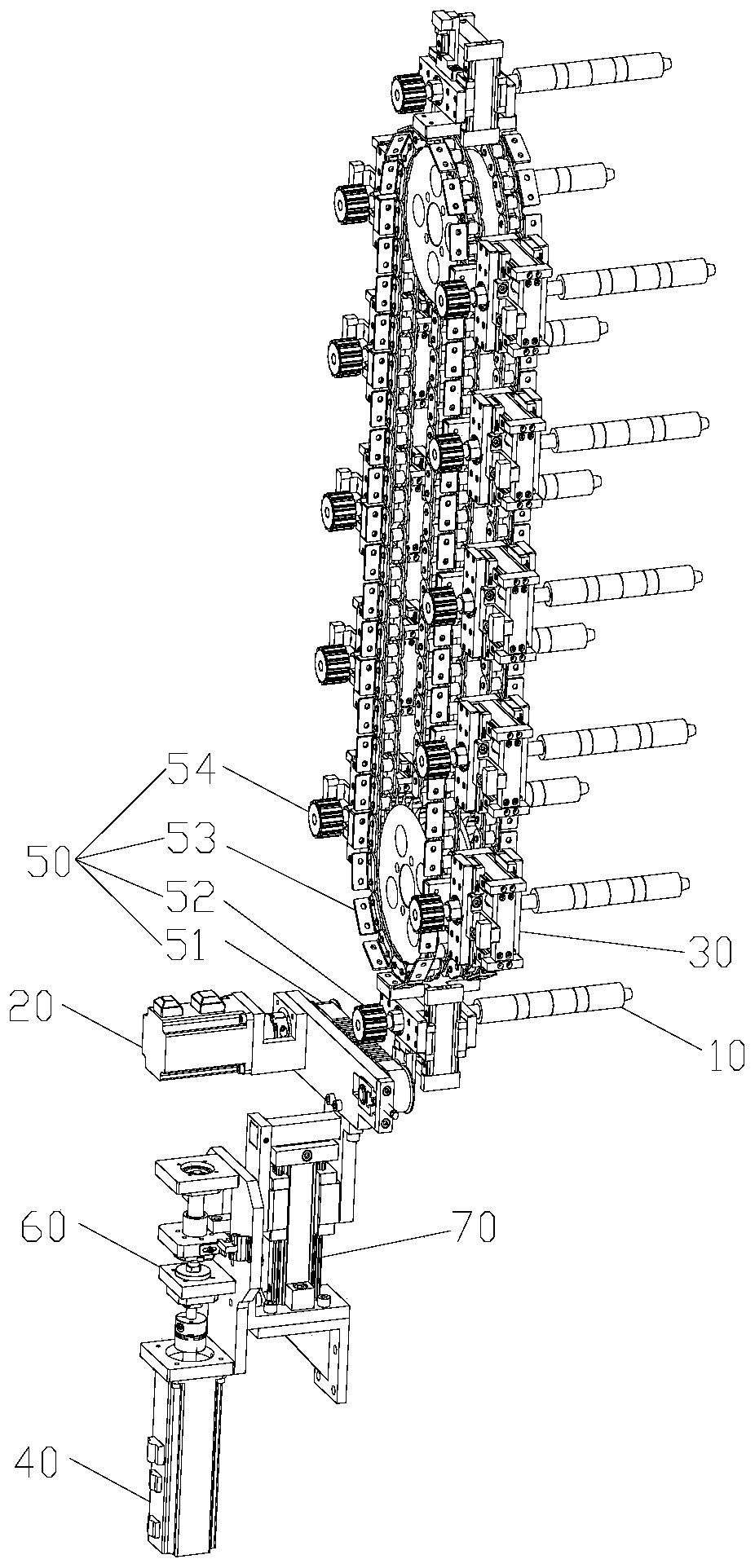

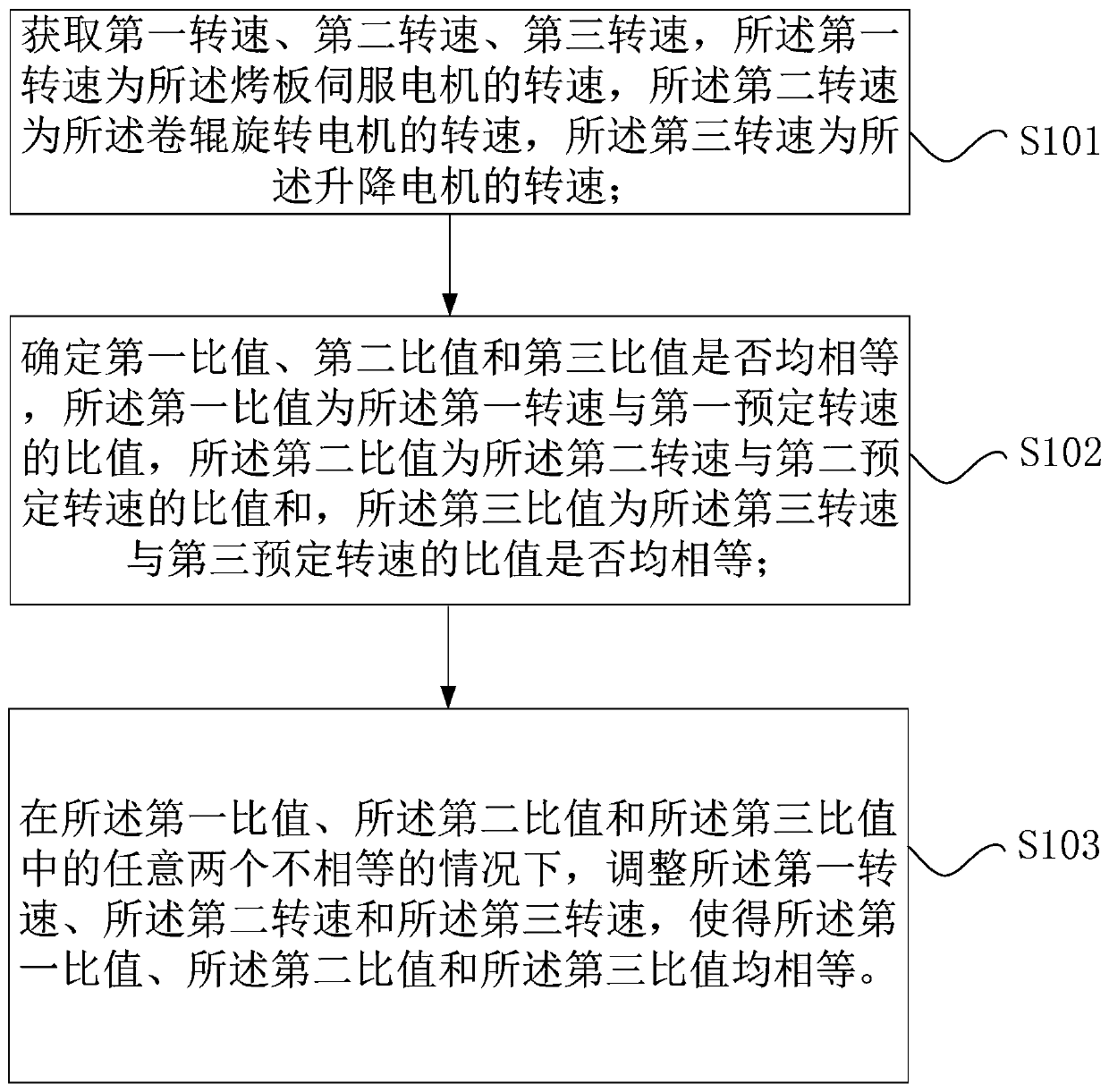

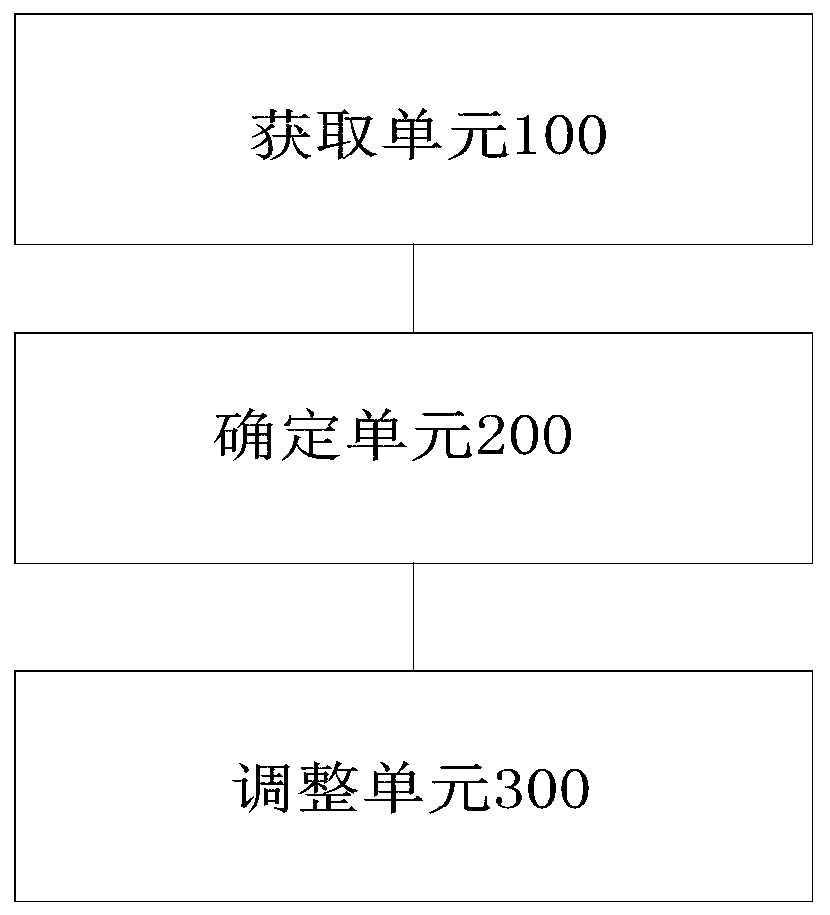

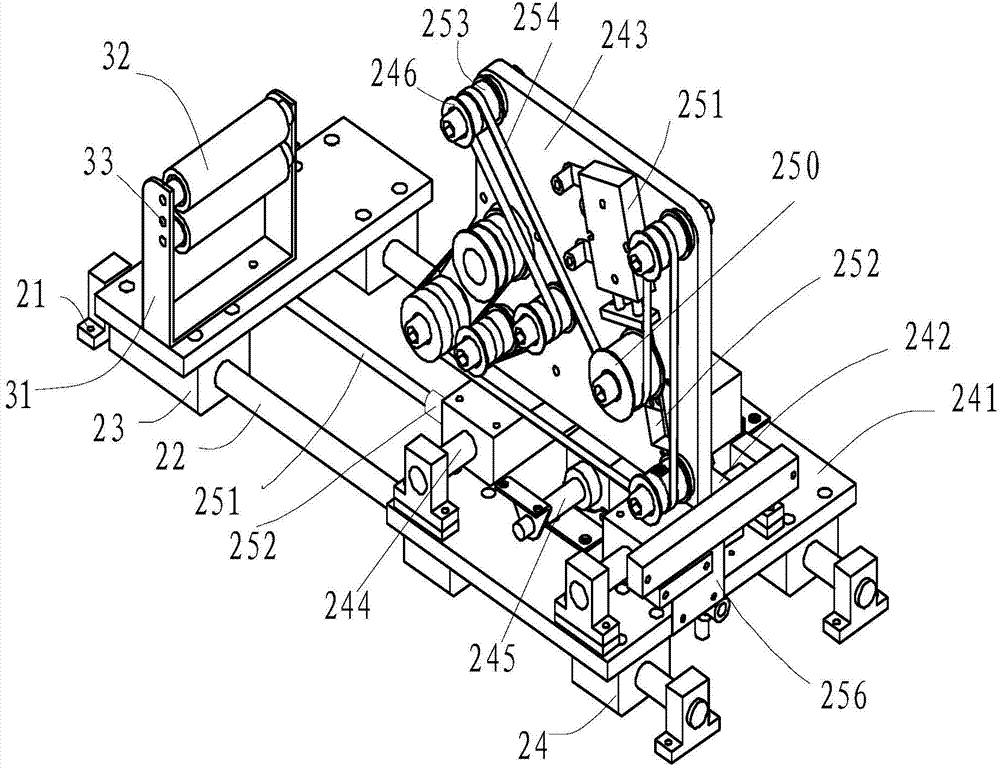

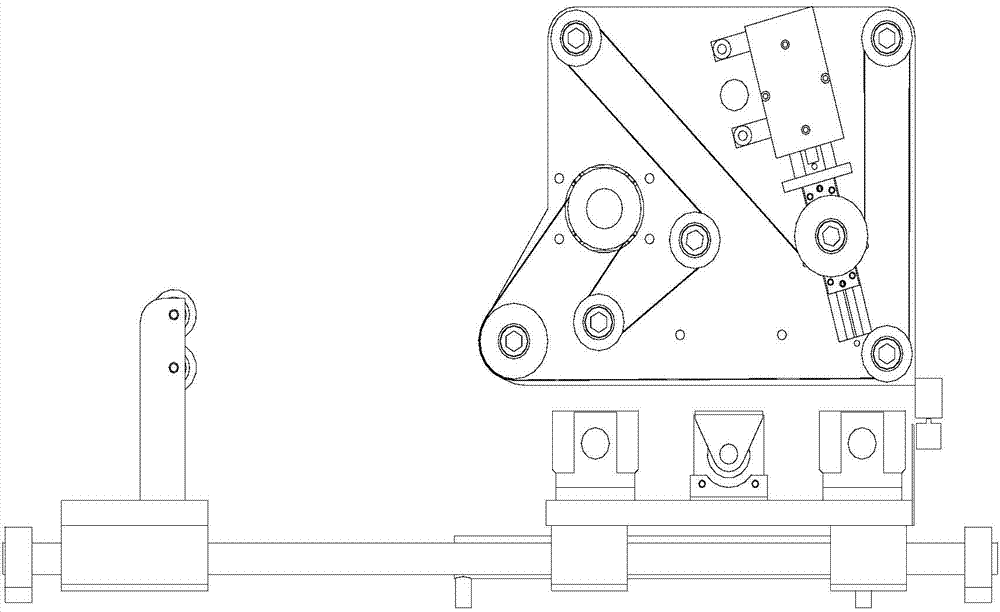

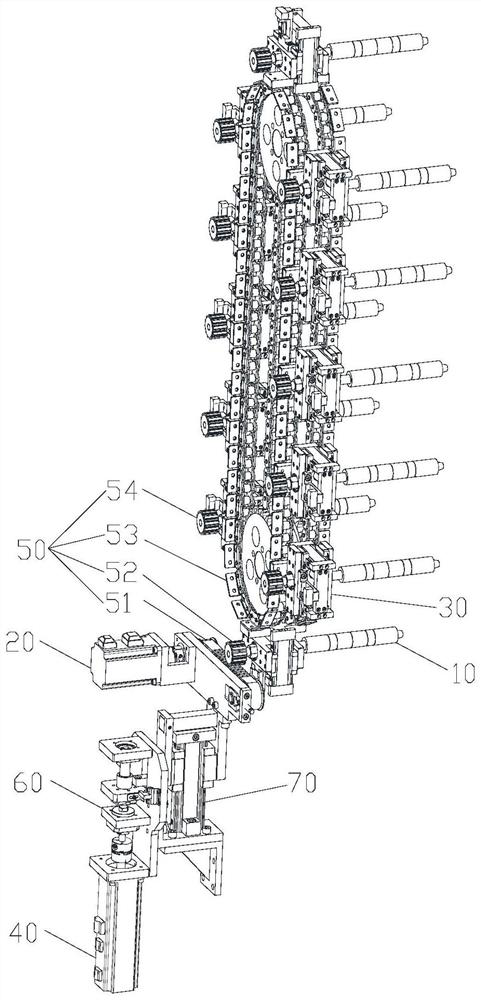

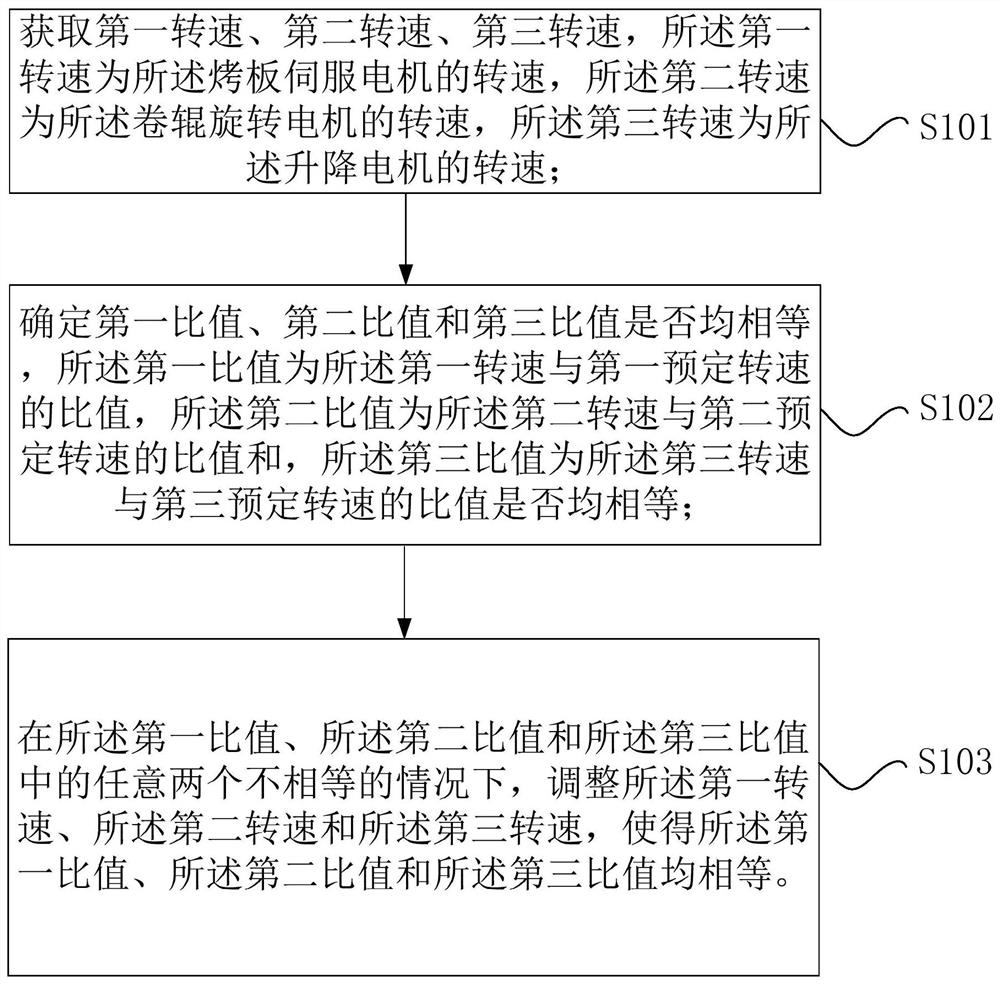

Control method and control device of egg roll making machine, storage medium and processor

ActiveCN111488021AImprove pass rateImprove stabilityMultiple dynamo-motor startersMultiple dynamo-electric motors speed regulationServoMechanical engineering

The invention provides a control method and device of an egg roll making machine, a storage medium and a processor. The control method comprises the steps: obtaining a first rotating speed, a second rotating speed and a third rotating speed, wherein the first rotating speed is the rotating speed of a baking plate servo motor, the second rotating speed is the rotating speed of a winding roller rotating motor, and the third rotating speed is the rotating speed of a lifting motor; determining whether a first ratio, a second ratio and a third ratio are equal or not, wherein the first ratio is theratio of the first rotating speed to the first preset rotating speed, the second ratio is the ratio of the second rotating speed to the second preset rotating speed, and the third ratio is the ratio of the third rotating speed to the third preset rotating speed; and under the condition that any two of the first ratio, the second ratio and the third ratio are not equal, adjusting the first rotatingspeed, the second rotating speed and the third rotating speed to make the first ratio, the second ratio and the third ratio equal, so that the rotating speed of the baking plate servo motor, the rotating speed of the winding roller rotating motor and the rotating speed of the lifting motor are kept synchronous in the winding process, and the percent of pass of egg rolls is increased.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

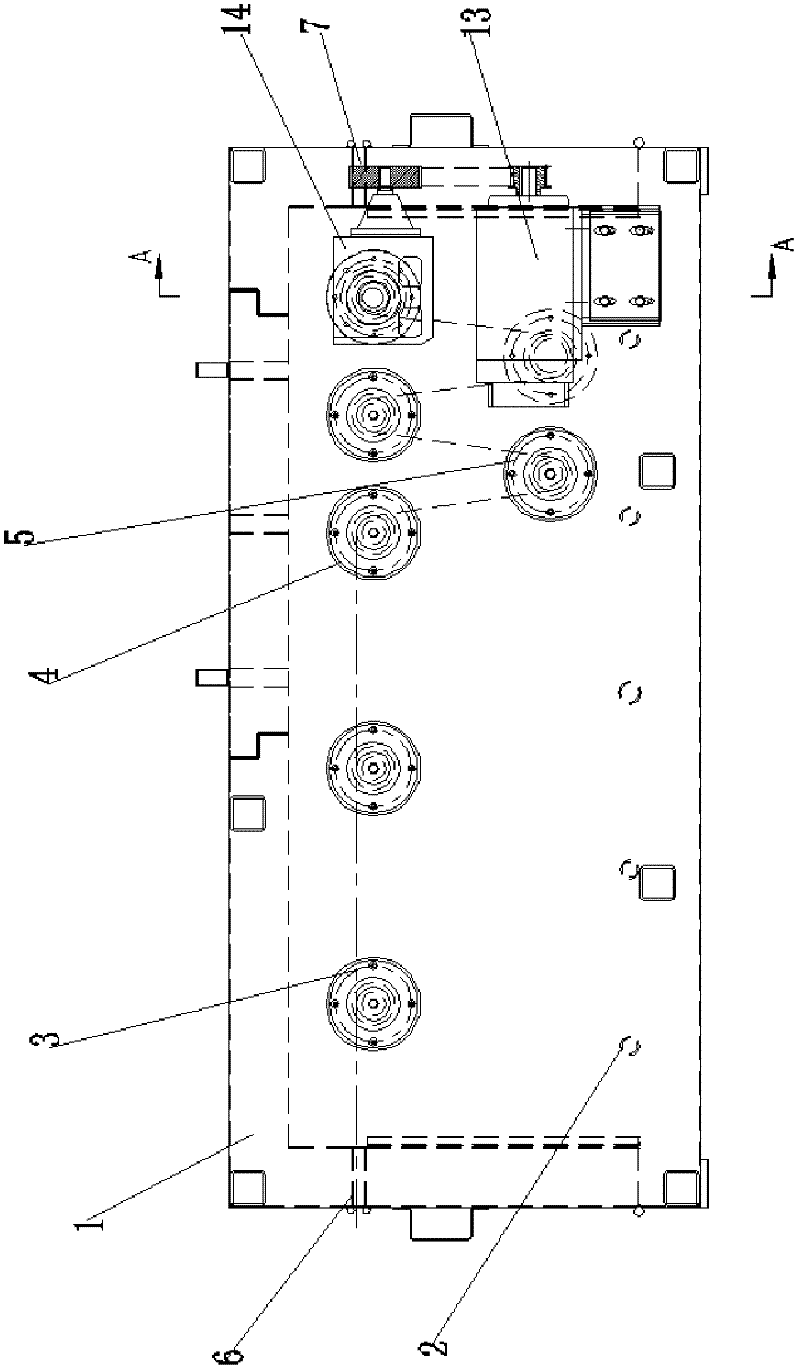

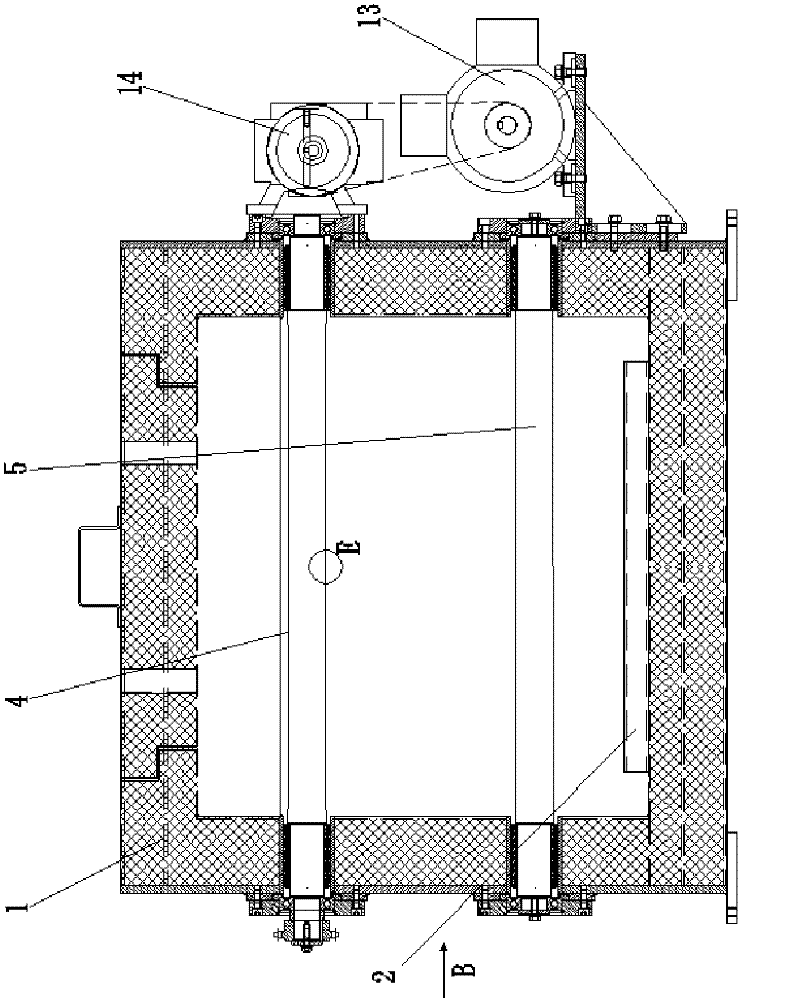

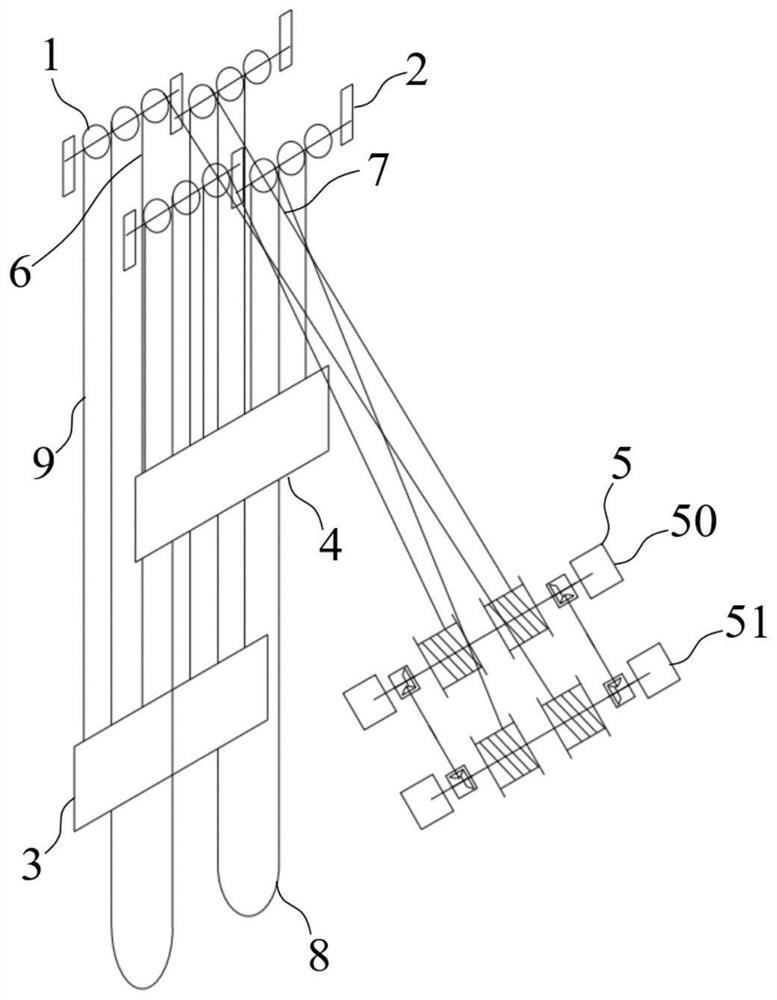

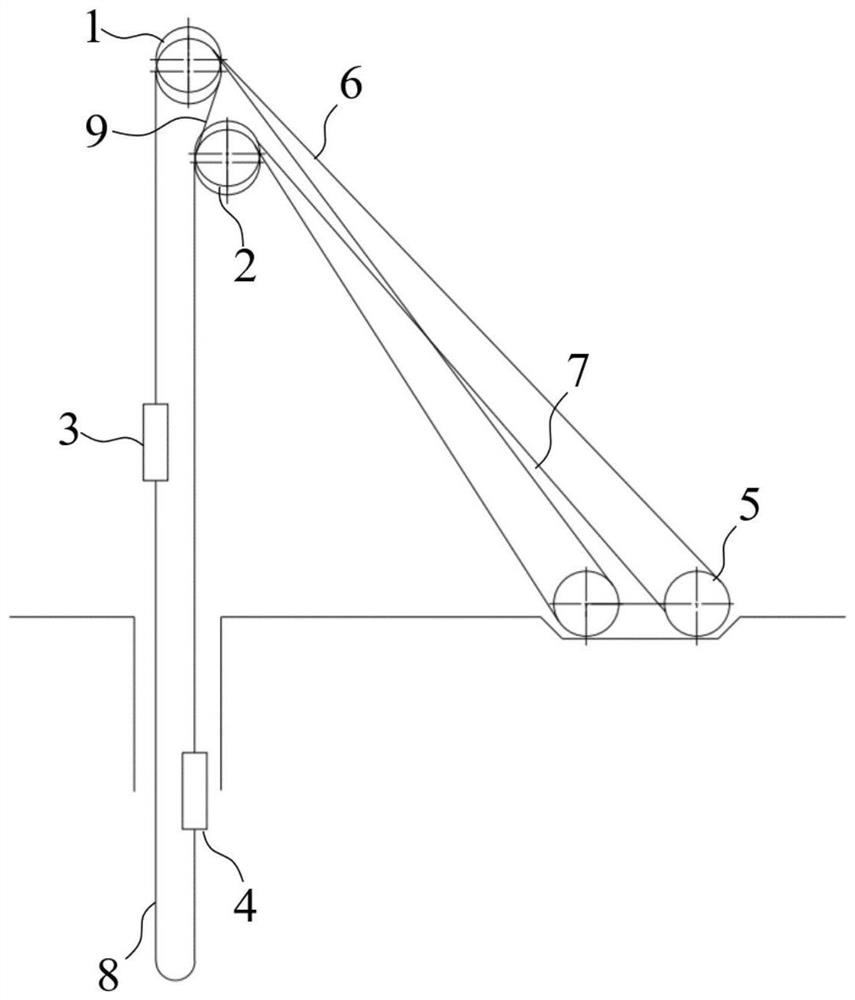

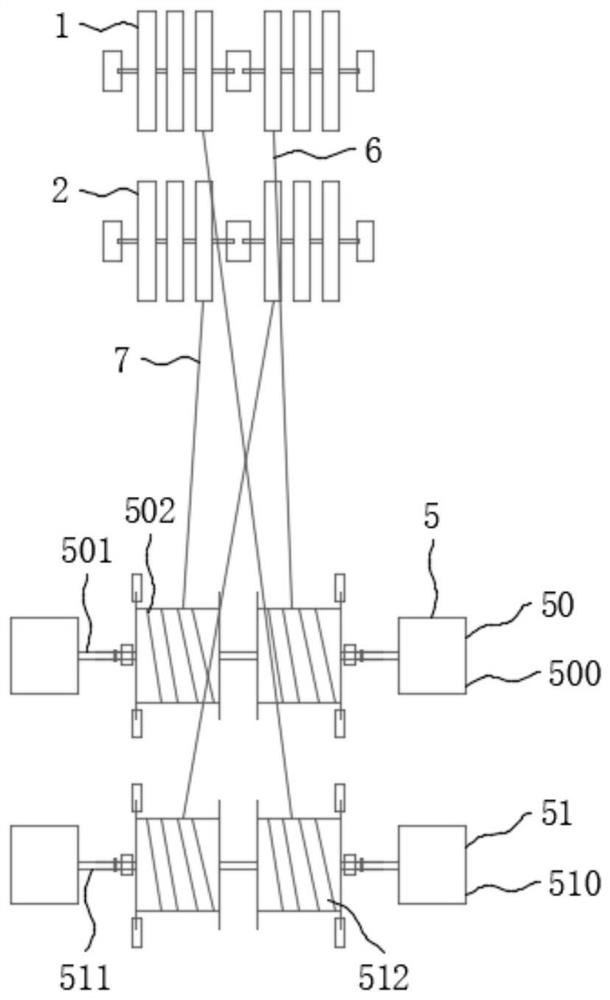

Multi-rope lifting system for ultra-deep vertical shaft and guiding method of multi-rope lifting system

ActiveCN112357724AReduce traction loadExtend effective lifeElevatorsMine liftsStructural engineeringMechanical engineering

The invention discloses a multi-rope lifting system for an ultra-deep vertical shaft and a guiding method of the multi-rope lifting system, and belongs to the technical field of mine lifting. The multi-rope lifting system comprises an upper guiding wheel system, a lower guiding wheel system, a front lifting container, a rear lifting container, a driving unit, a front lifting rope, a rear lifting rope, a tail rope and a plurality of balance head ropes, wherein the front lifting rope is lapped on the upper guiding wheel system, one end of the front lifting rope is connected with the top of the front lifting container, and the other end of the front lifting rope is connected with the driving unit; the rear lifting rope is lapped on the lower guiding wheel system, one end of the rear lifting rope is connected with the top of the rear lifting container, and the other end of the rear lifting rope is connected with the driving unit; one end of the tail rope is connected with the bottom of thefront lifting container, and the other end of the tail rope is connected with the bottom of the rear lifting container; and the balance head ropes are lapped on the upper guiding wheel system, one end of each balance head rope is connected with the top of the front lifting container, and the other end of each balance head rope is connected with the top of the rear lifting container. According tothe multi-rope lifting system, the balance head ropes are arranged, so that the traction load borne by the driving unit is greatly reduced, the effective service life of the driving unit is greatly prolonged, and the multi-rope lifting system for the ultra-deep vertical shaft can carry out lifting operation with larger load.

Owner:CHINA UNIV OF MINING & TECH

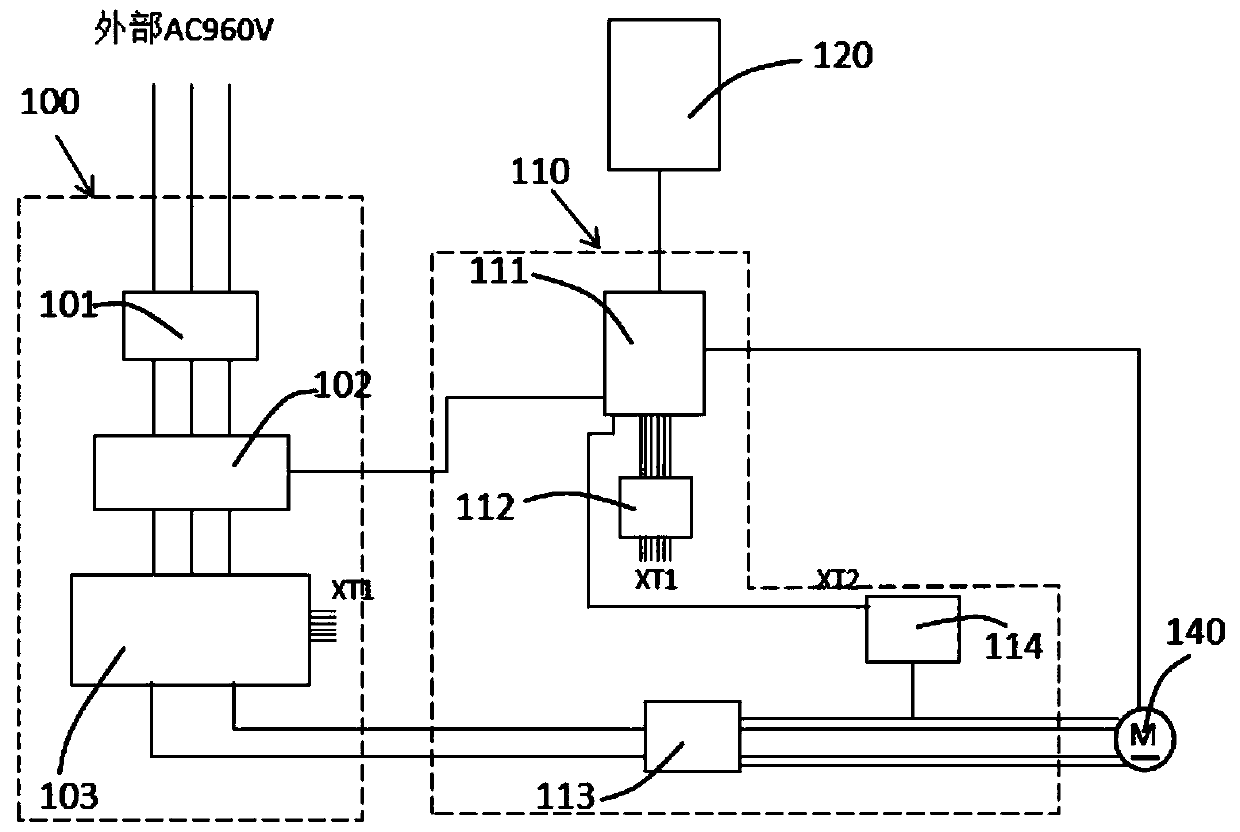

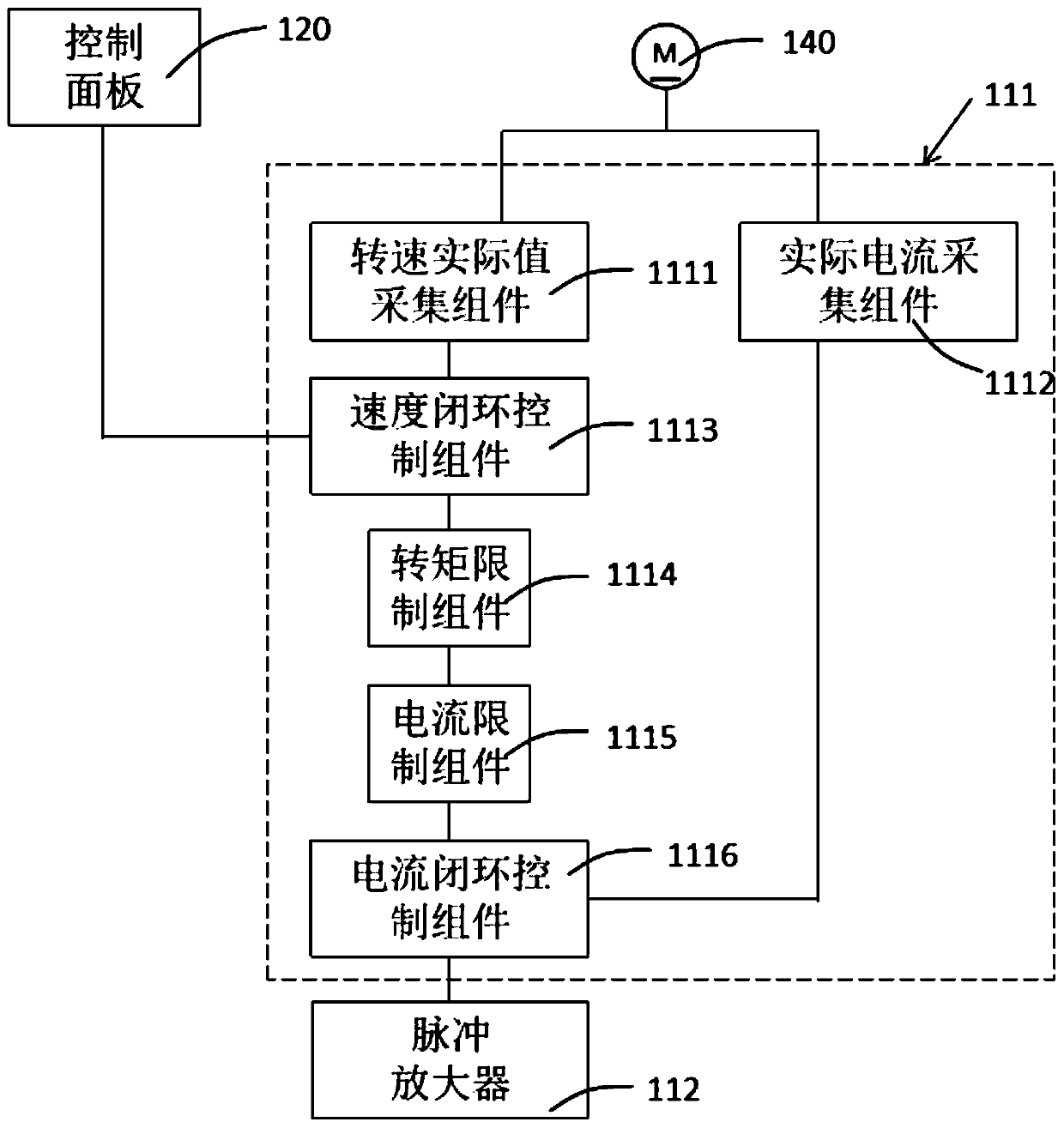

DC motor speed-regulation device and method

InactiveCN109787519ALow costMeet driving needsField or armature current controlMultiple dynamo-electric motors speed regulationLoop controlCurrent limiting

The invention discloses a DC motor speed-regulation device for a drilling platform. The device comprises a rectifier module including a thyristor; a control module including a DC speed regulator and apulse amplifier, wherein one end of the pulse amplifier is connected with the DC speed regulator, and the other end is connected to the thyristor; the DC speed regulator comprises a rotating speed actual value collecting module, a speed closed loop control module, a torque limiting component, a current limiting component and a current closed loop control component connected in order; and an actual collection component connected with the current closed loop control component, wherein the DC speed regulator is connected with the DC motor. The invention further discloses a DC motor speed-regulation method. The DC motor is controlled by adopting a way of combining the DC speed regulator and the pulse amplifier;, the rotating speed of the DC motor is monitored in real time, and a torque sensoris increased between the drilling motor and a drilling rig to collect the torque data in real time, thereby reaching the aims of outputting different torques of different geological conditions, reducing the loss of a transmission system, lowering a well drilling cost, and saving energy.

Owner:湖南鼎创装备有限公司

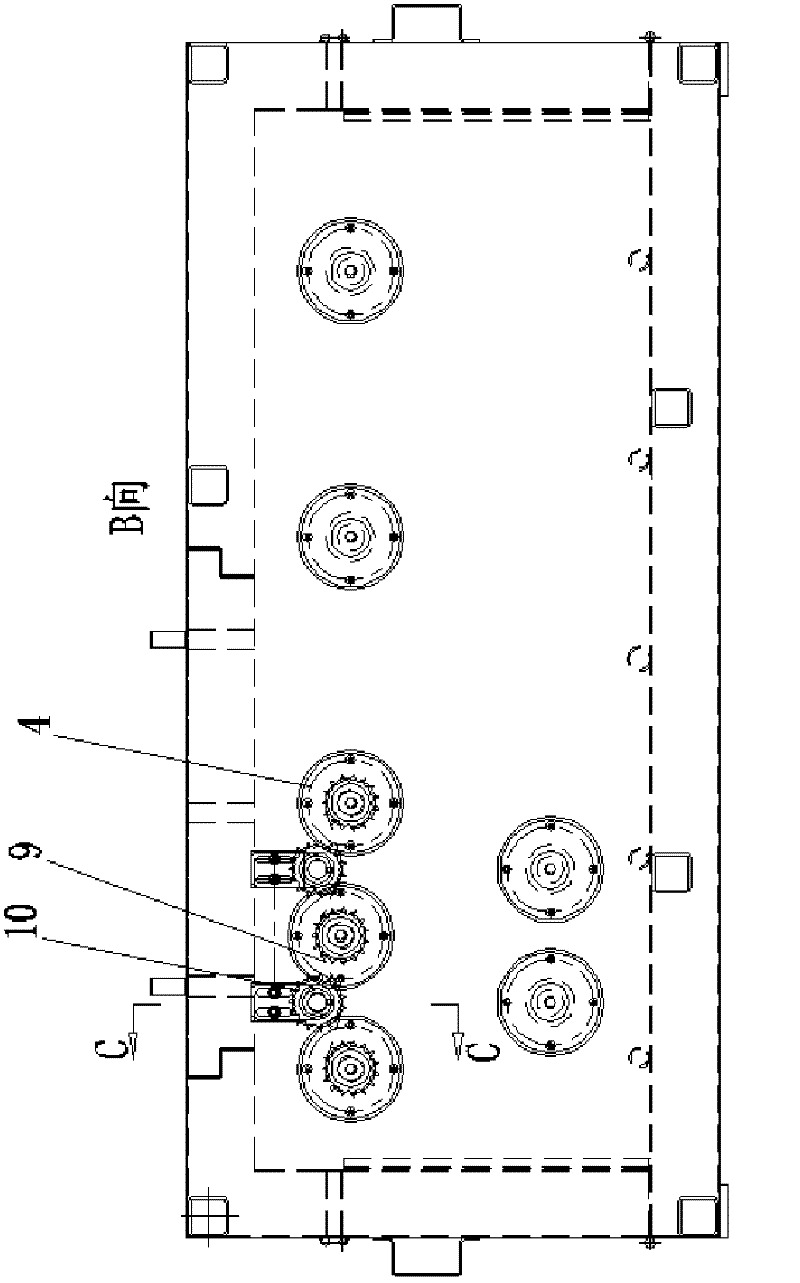

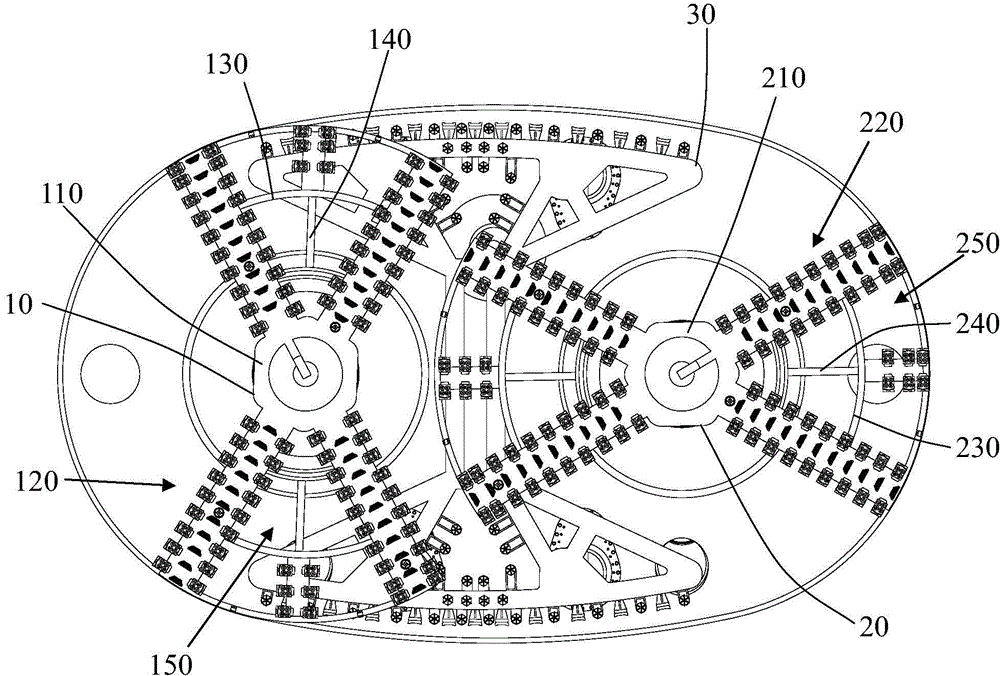

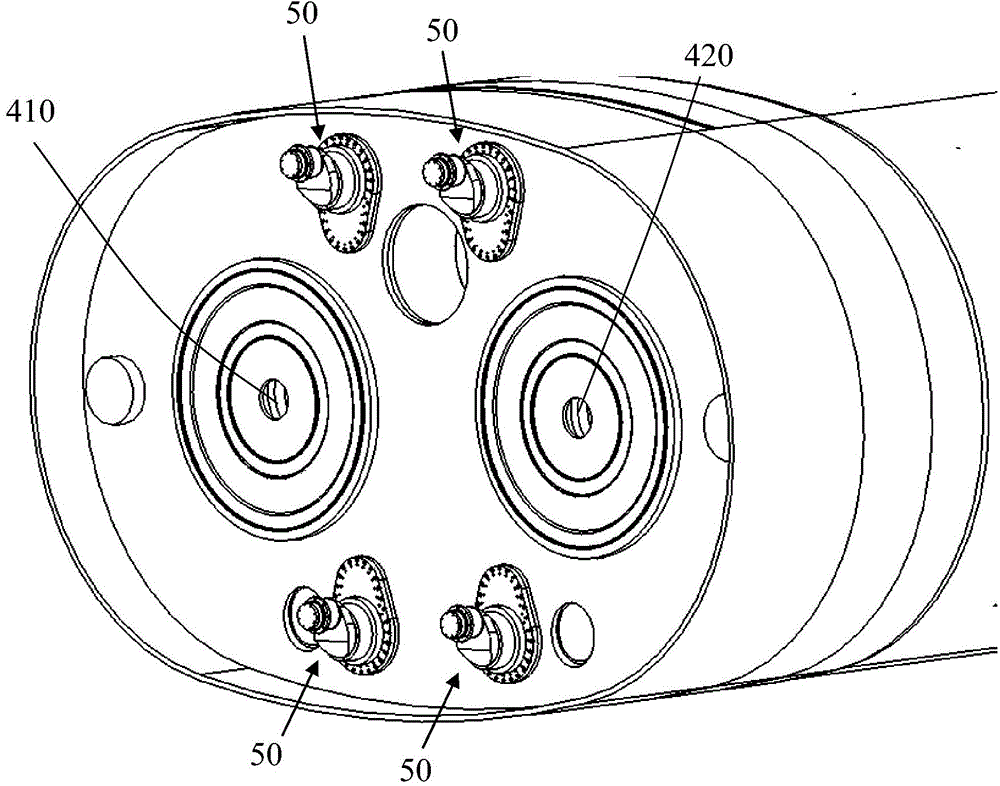

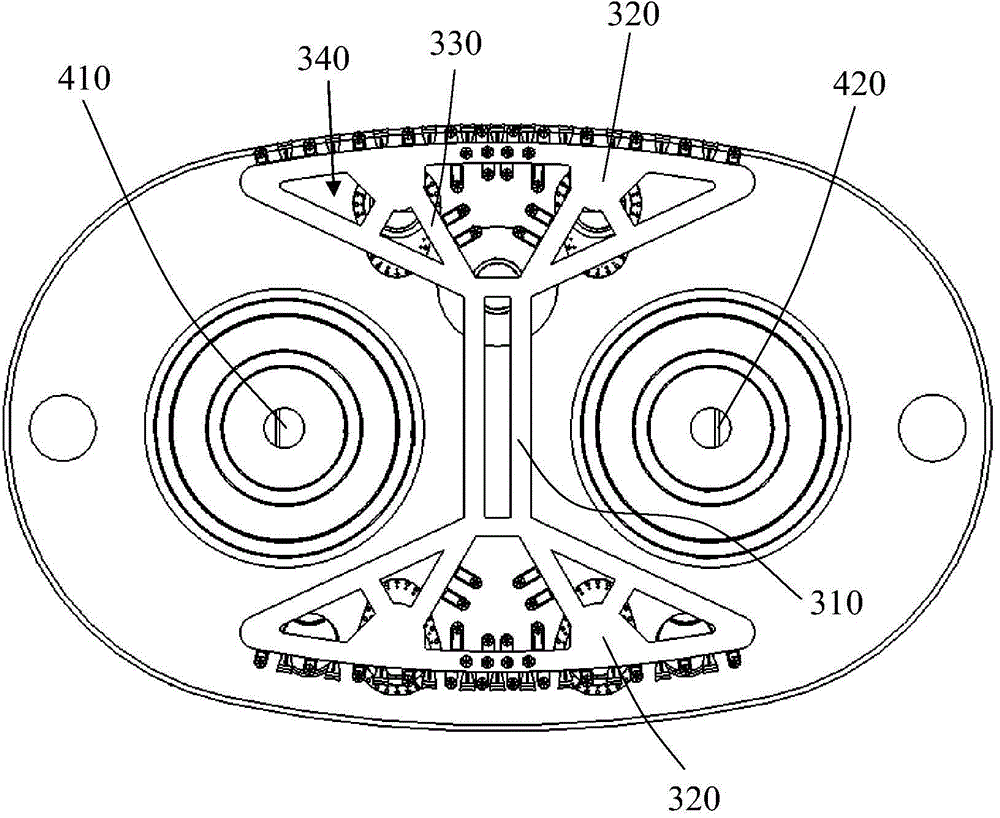

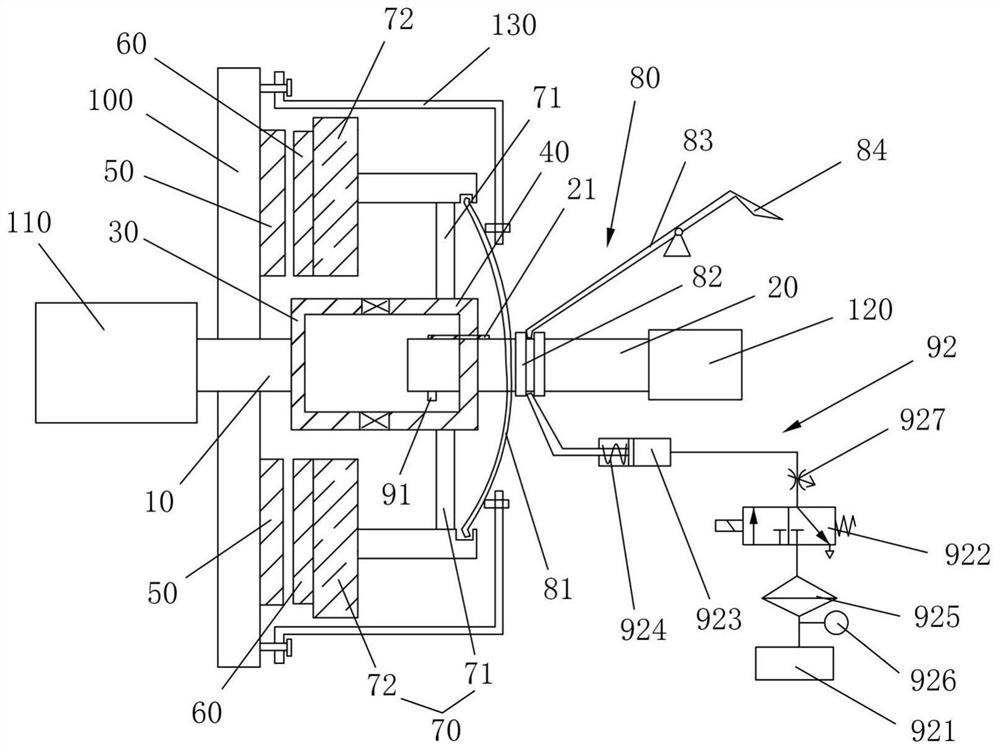

Rectangular shield cutter head device and synchronous control method thereof

The invention discloses a rectangular shield cutter head device and a synchronous control method of the rectangular shield cutter head device. The cutter head device comprises a first cutter head, a second cutter head, an eccentric multi-axis special-shaped cutter head, a first cutter head driver, a second cutter head driver and an eccentric multi-axis special-shaped cutter head driver, wherein the first cutter head and the second cutter head are arranged on a front section shell at a set angle difference, the eccentric multi-axis special-shaped cutter head is located behind the first cutter head and the second cutter head, the first cutter head driver is used for driving the first cutter head to conduct circular motion, the second cutter head driver is used for driving the second cutter head to conduct circular motion, and the eccentric multi-axis special-shaped cutter head driver is used for driving the eccentric multi-axis special-shaped cutter head to conduct eccentric rotational motion. The first cutter head and the second cutter head are X-shaped spoke type structure cutter heads, the set angle difference ranges from 80 degrees to 100 degrees, and the center distance of the first cutter head and the second cutter head is smaller than the sum of the radius of the first cutter head and the radius of the second cutter head. The first cutter head and the second cutter head do not collide with each other and conduct excavation on a first work face, the eccentric multi-axis special-shaped cutter head conducts cutting on a second work face, the whole cutter head device conducts cutting in a rectangular section at the maximum area, the whole excavation face is made to be rectangular, and full section cutting is achieved.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

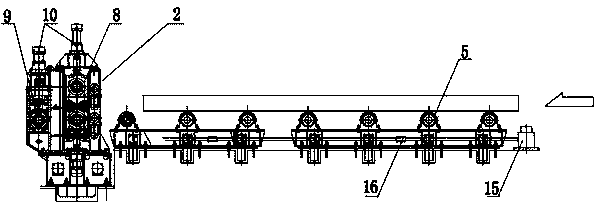

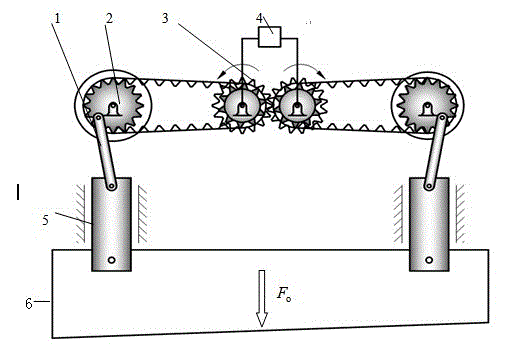

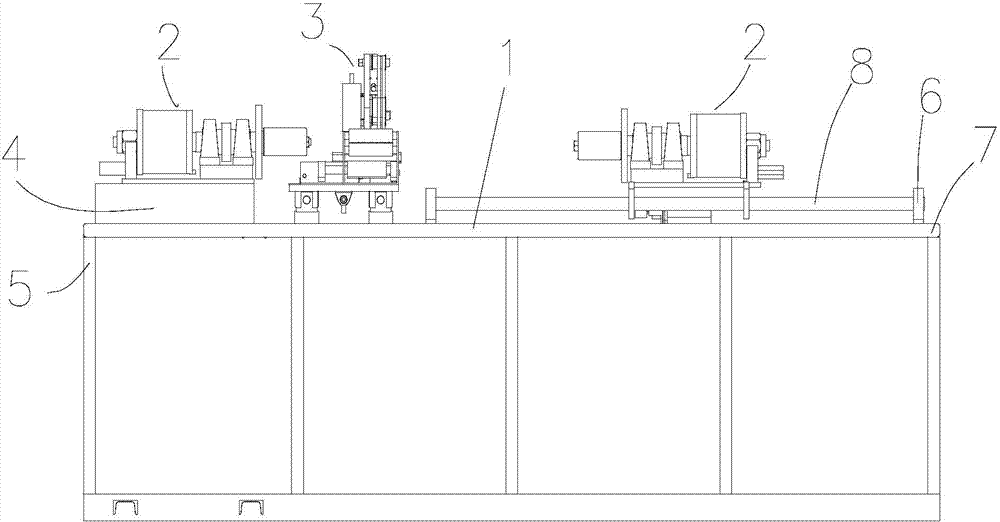

Driving device of gear-synchronous cog belt numerical control plate shearing machine

InactiveCN102744453AAverage drive accuracyHigh transmission precisionShearing machinesLinear motionEngineering

The invention discloses a driving device of a gear-synchronous cog belt numerical control plate shearing machine. The driving device of the gear-synchronous cog belt numerical control plate shearing machine comprises a power device, a transmission device, a control device and a movable knife rest and is characterized in that the power device is a servo motor, the transmission device comprises a gear, a synchronous toothed wheel, a synchronous cog belt, a connecting rod and a sliding block, wherein the gear, the synchronous cog belt, the connecting rod and the sliding block are arranged on an output shaft of the servo motor. The gear and the synchronous toothed wheel are in transmission through the synchronous cog belt, one end of the connecting rod is in transmission connection with the synchronous toothed wheel, the other end of the connecting rod is in transmission connection with one end of the sliding block, the other end of the sliding block is fixedly connected with the movable knife rest, the sliding block is limited by a linear motion limit mechanism which is consistent with the motion direction of the movable knife rest, and the control device is a numerical control system. The driving device of the gear-synchronous cog belt numerical control plate shearing machine achieves shearing of wide plates, improves working capacity, simultaneously is ingenious in design, has belt transmission, gear transmission and chain transmission, can effectively guarantee shearing accuracy, improves working efficiency, is simple in structure, and reduces manufacturing cost.

Owner:SUZHOU UNIV

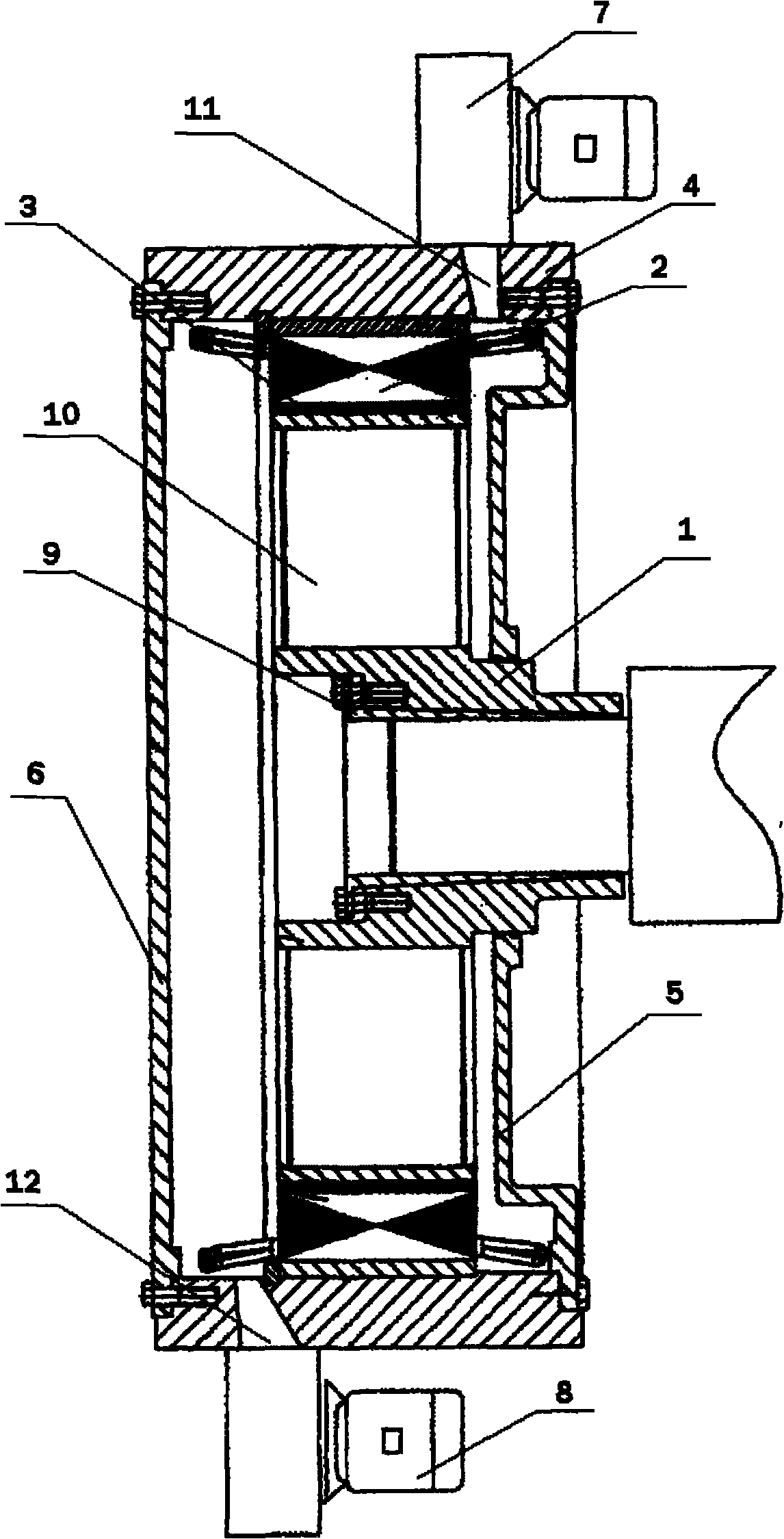

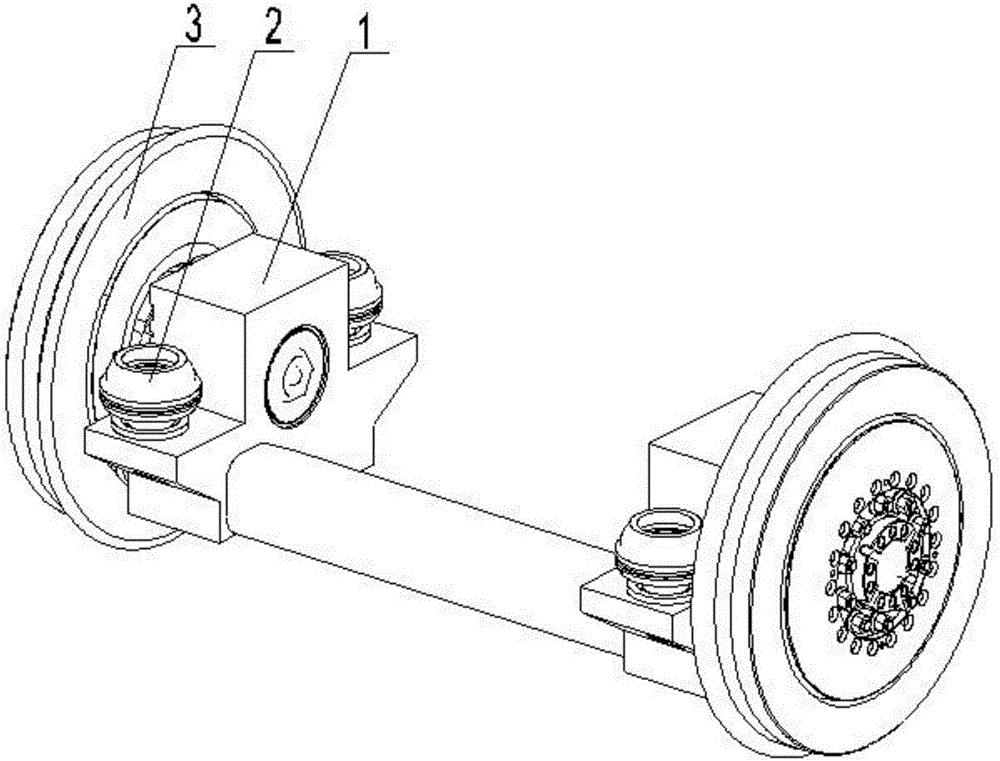

Wheel pair axle box device enabling rotating speed of left wheel and that of right wheel of low floor light rail bogie to be synchronous

InactiveCN106585656AReduce rim wearExtended service lifeAxle-boxes mountingLight railAutomotive engineering

The invention relates to a wheel pair axle box device enabling the rotating speed of a left wheel and that of a right wheel of a low floor light rail bogie to be synchronous. The wheel pair axle box device comprises an axle, elastic wheels and a vehicle shaft, wherein the elastic wheels are connected with the vehicle shaft through a flange surface fastener; and the vehicle shaft is fixed by a bearing mounted in the axle and a bearing in the flange connecting seat. The wheel pair axle box device is characterized in that one transmission bull wheel is arranged between two sets of single-column tapered roller bearings for fixing the vehicle shaft in a clamping manner; a transmission shaft for enabling the rotating speeds of the wheels on two sides to be synchronous is fixed in the axle through the two single-column tapered roller bearings on the two sides; transmission pinions are arranged on the transmission shaft; and the transmission shaft is in transmission connection with the vehicle shaft through the meshing of each of the transmission bull wheels and the corresponding transmission pinions. According to the wheel pair axle box device disclosed by the invention, through the transmission shaft and the meshing of a set of the bull wheels and the pinions integrated in the axle, the wheel on the left side and the wheel on the right side of an independent wheel steering frame are coupled, so that the rotating speeds of the wheels on the two sides are synchronous, the wheel flange eccentric wear is reduced, the service life of the wheels is prolonged, and the maintenance cost of the vehicle is reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

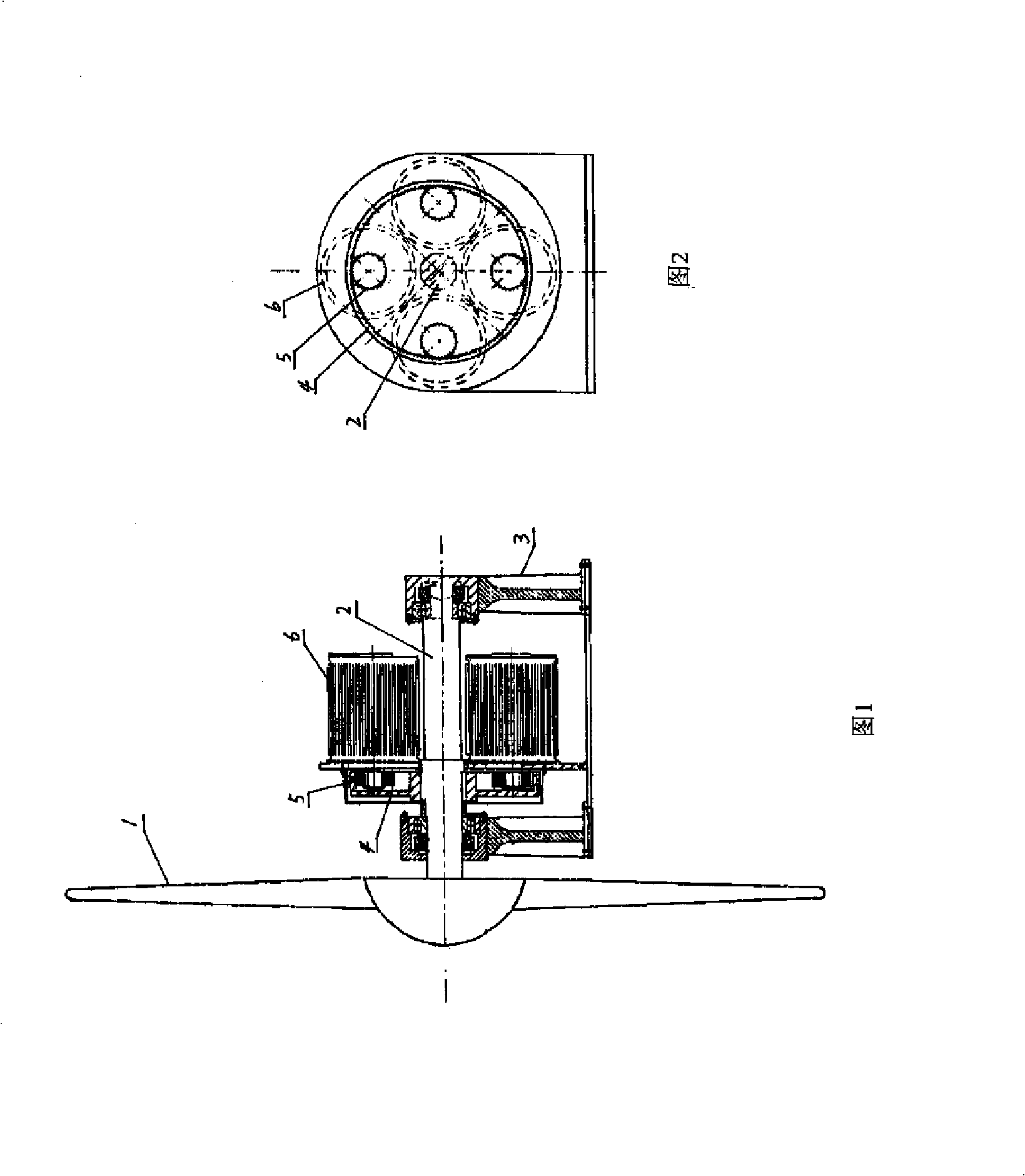

One-axis multi-machine speeding wind generator set

InactiveCN101344072AReduce manufacturing costReliable technologyToothed gearingsMachines/enginesRotational axisLow speed

The invention relates to a wind power generating set, namely a speed-increasing wind power generating set with one shaft and multiple machines; the invention comprises a rotating shaft with rotating blades and a permanent-magnet multistage generator; the rotating shaft is provided with a large inner gear and at least two or more than two small outer gears which are meshed with the large inner gear, and each small outer gear is connected with an input shaft of the permanent-magnet multistage generator correspondingly; a plurality of generators with permanent magnet, multiple stage, low speed and low power are combined to be used, and realize synchronous speed-increasing with the same speed; the invention is characterized by simple and compact structure, low cost, reliable technology, convenient maintenance and long operation life.

Owner:姜星柱

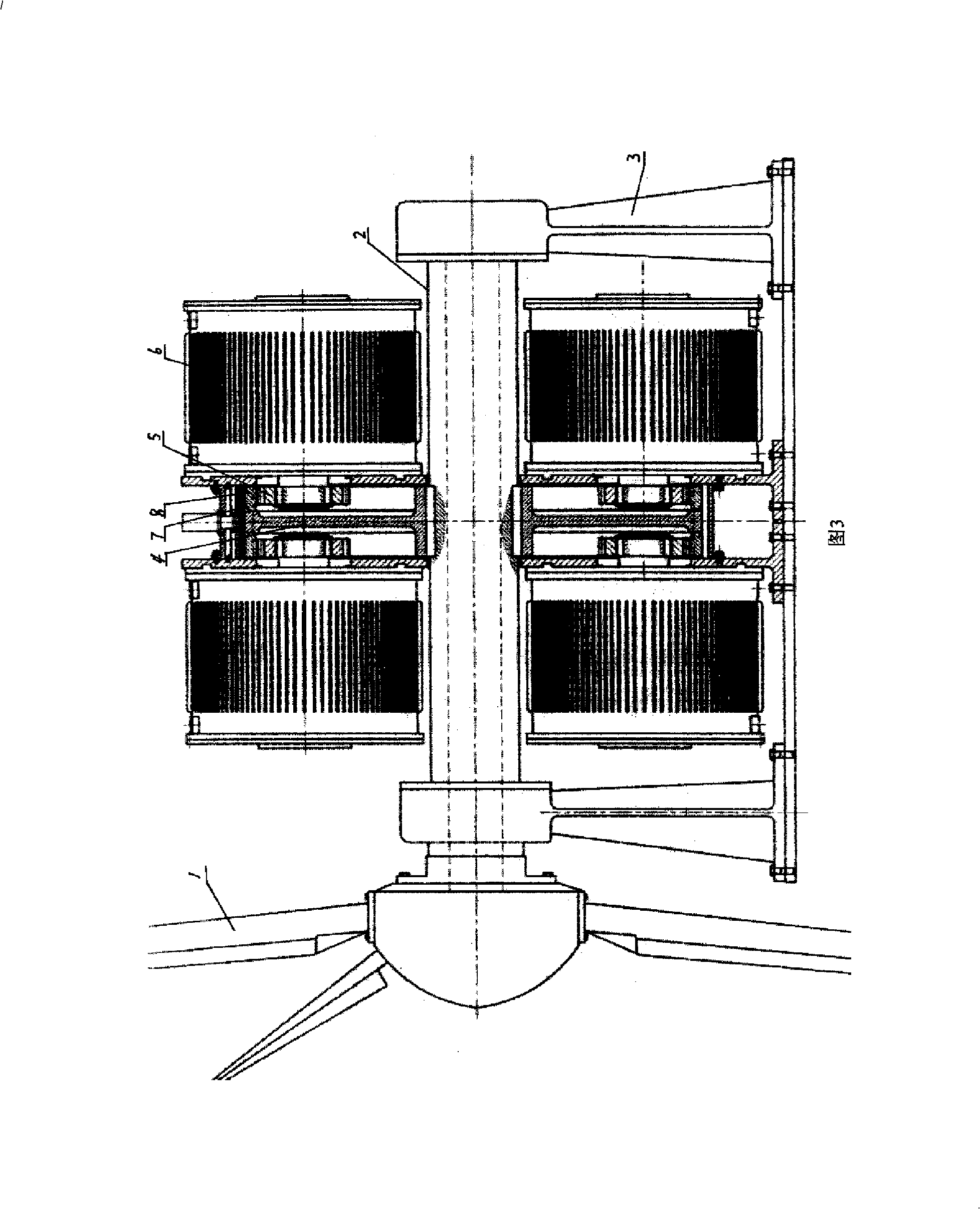

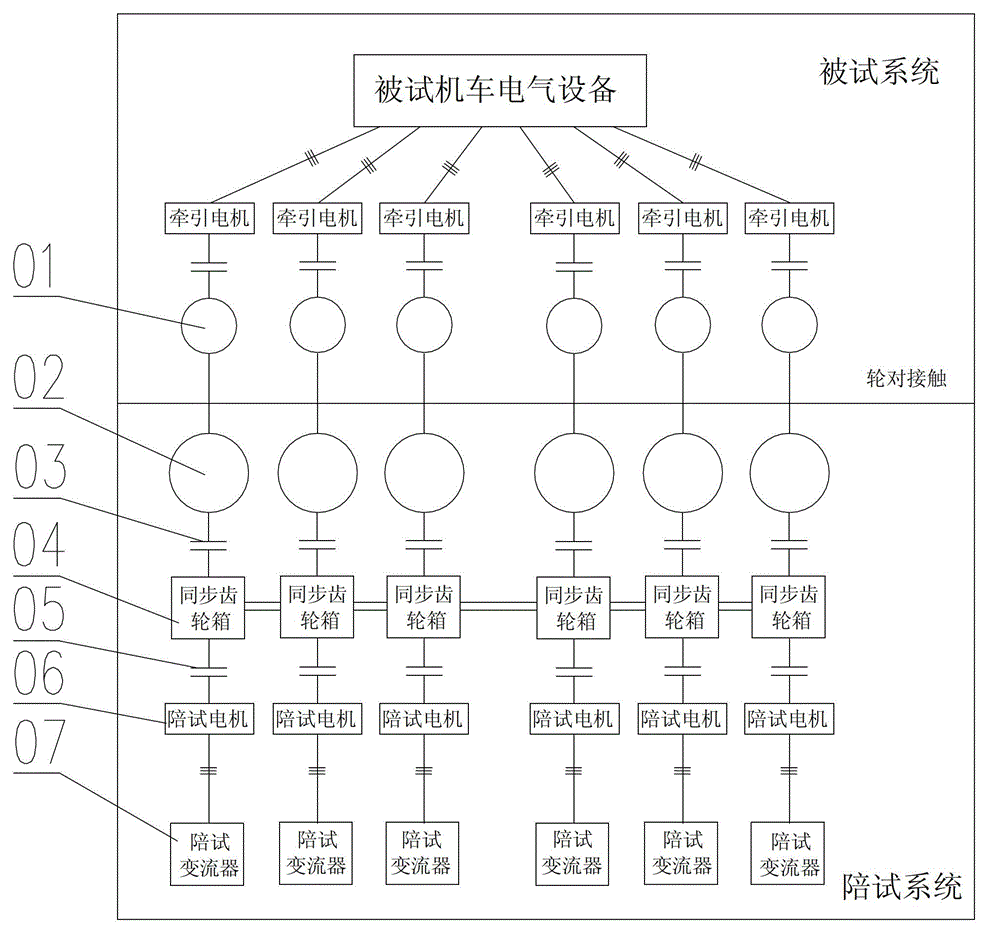

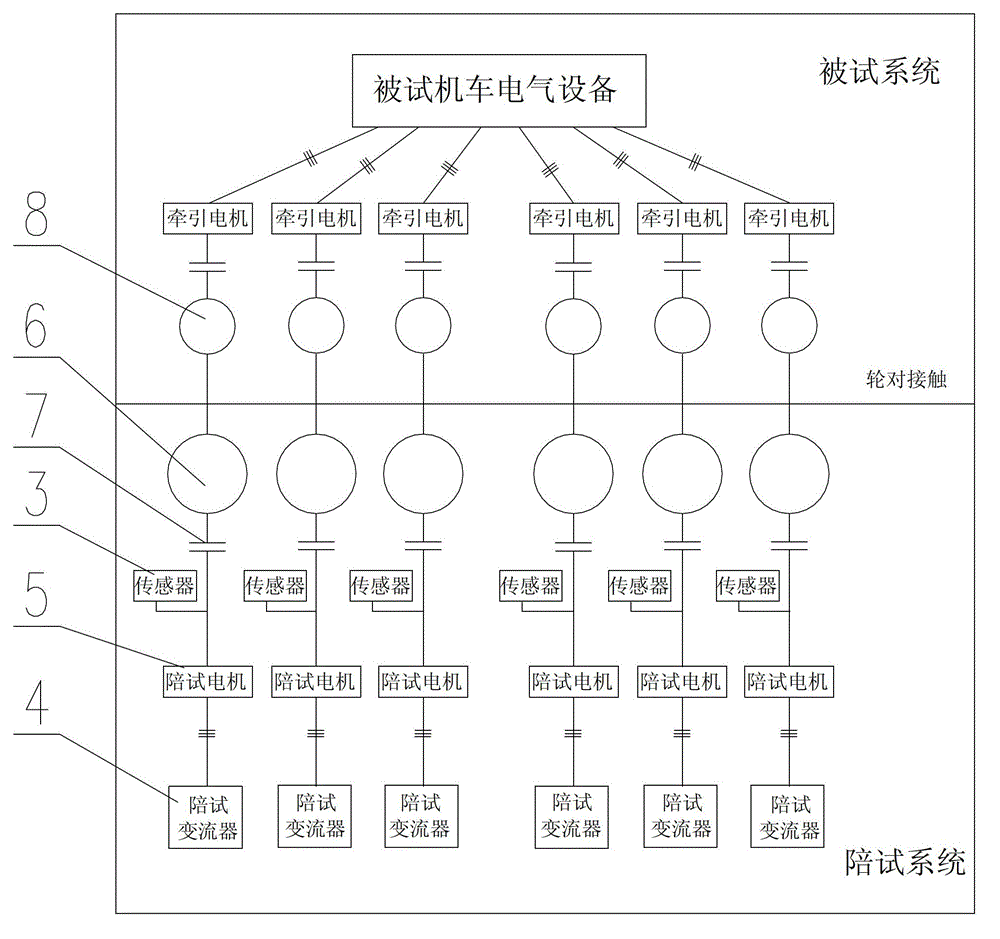

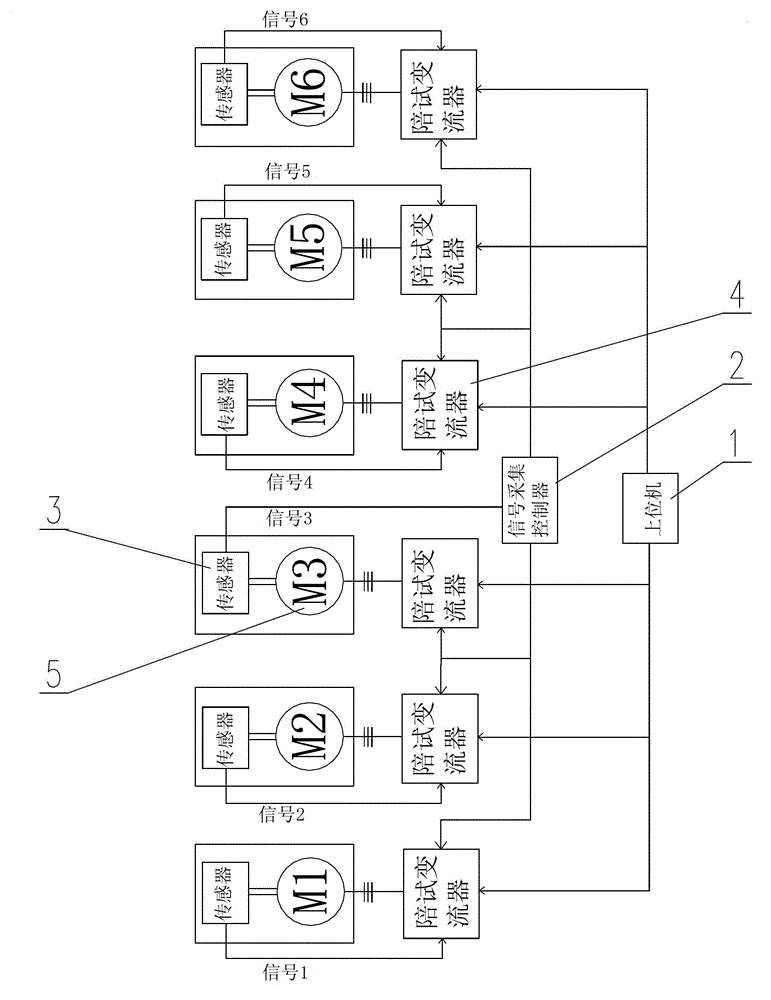

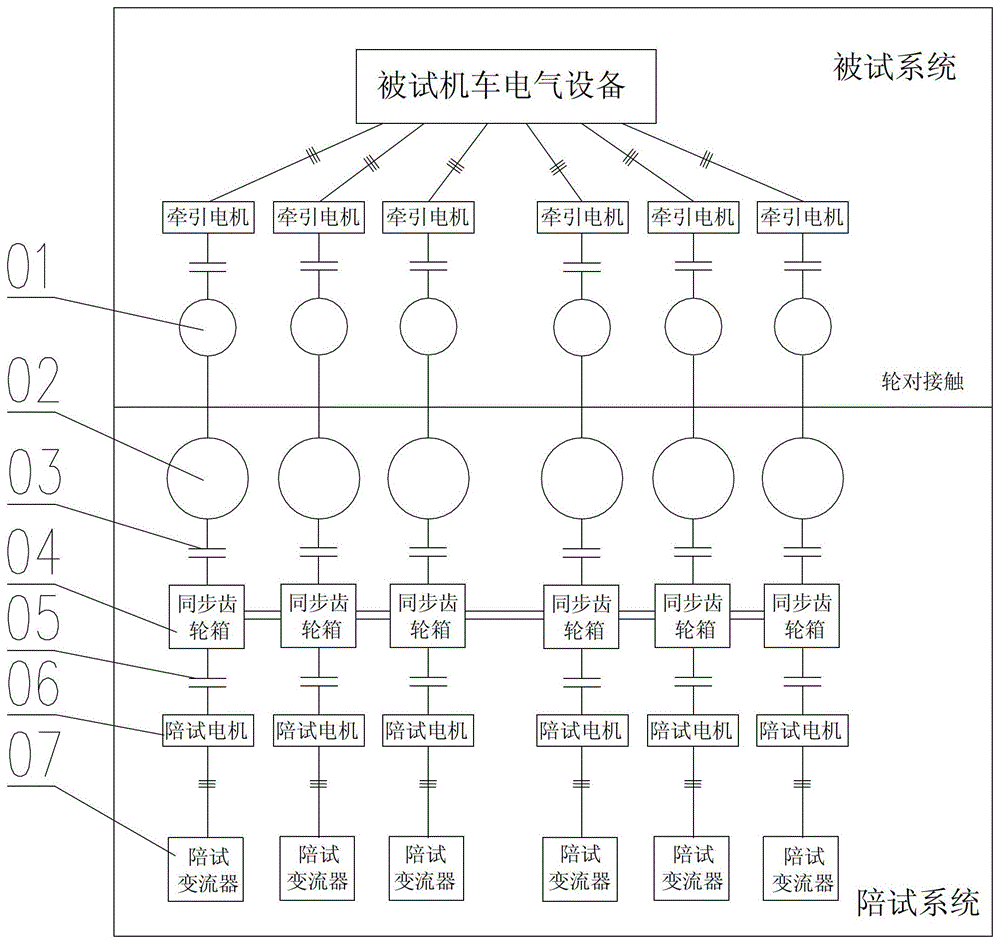

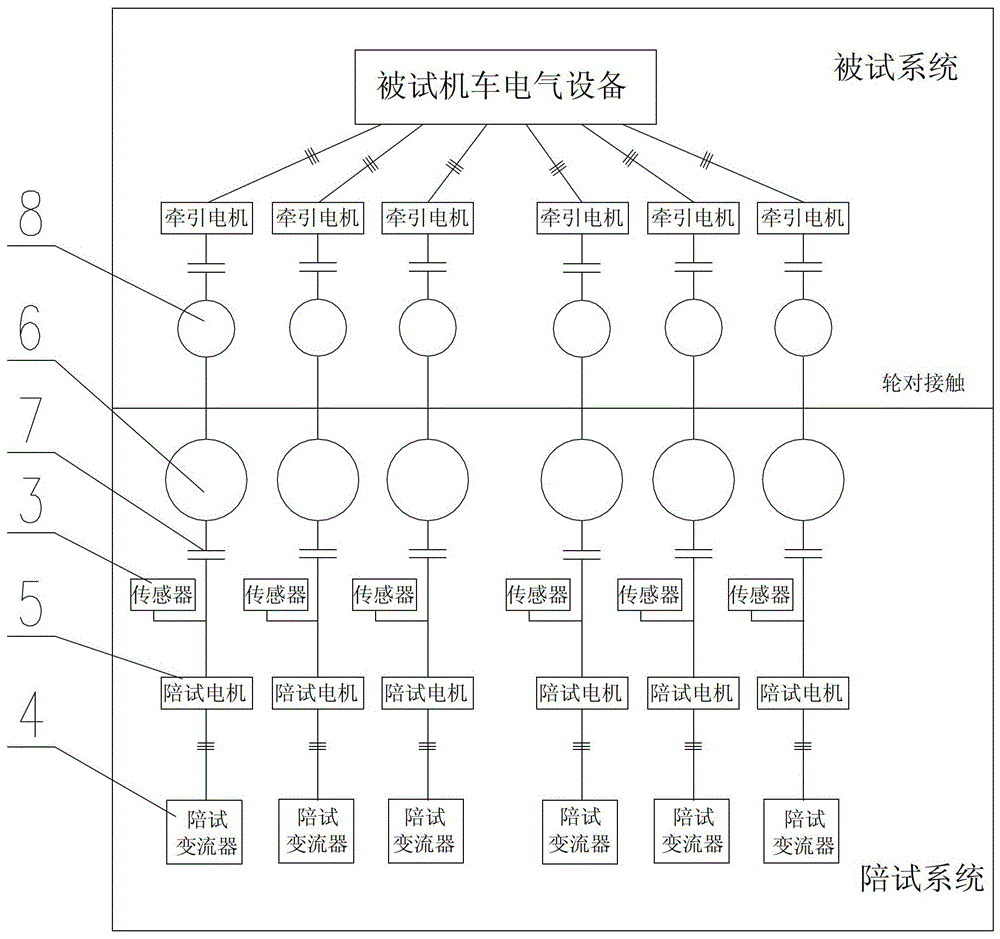

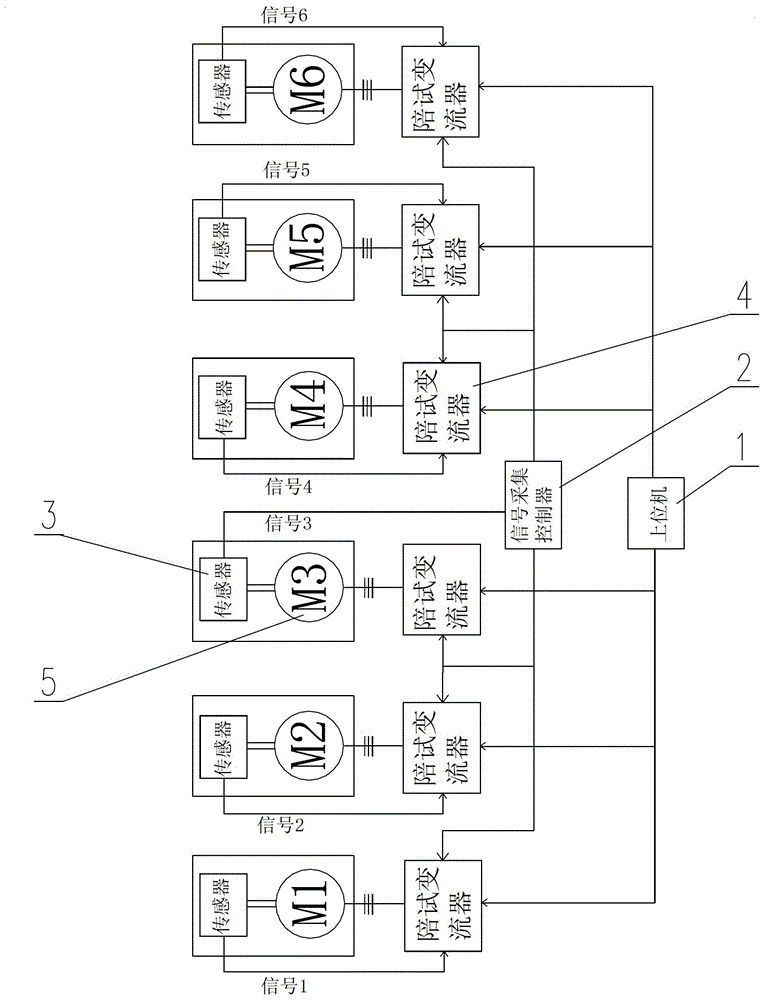

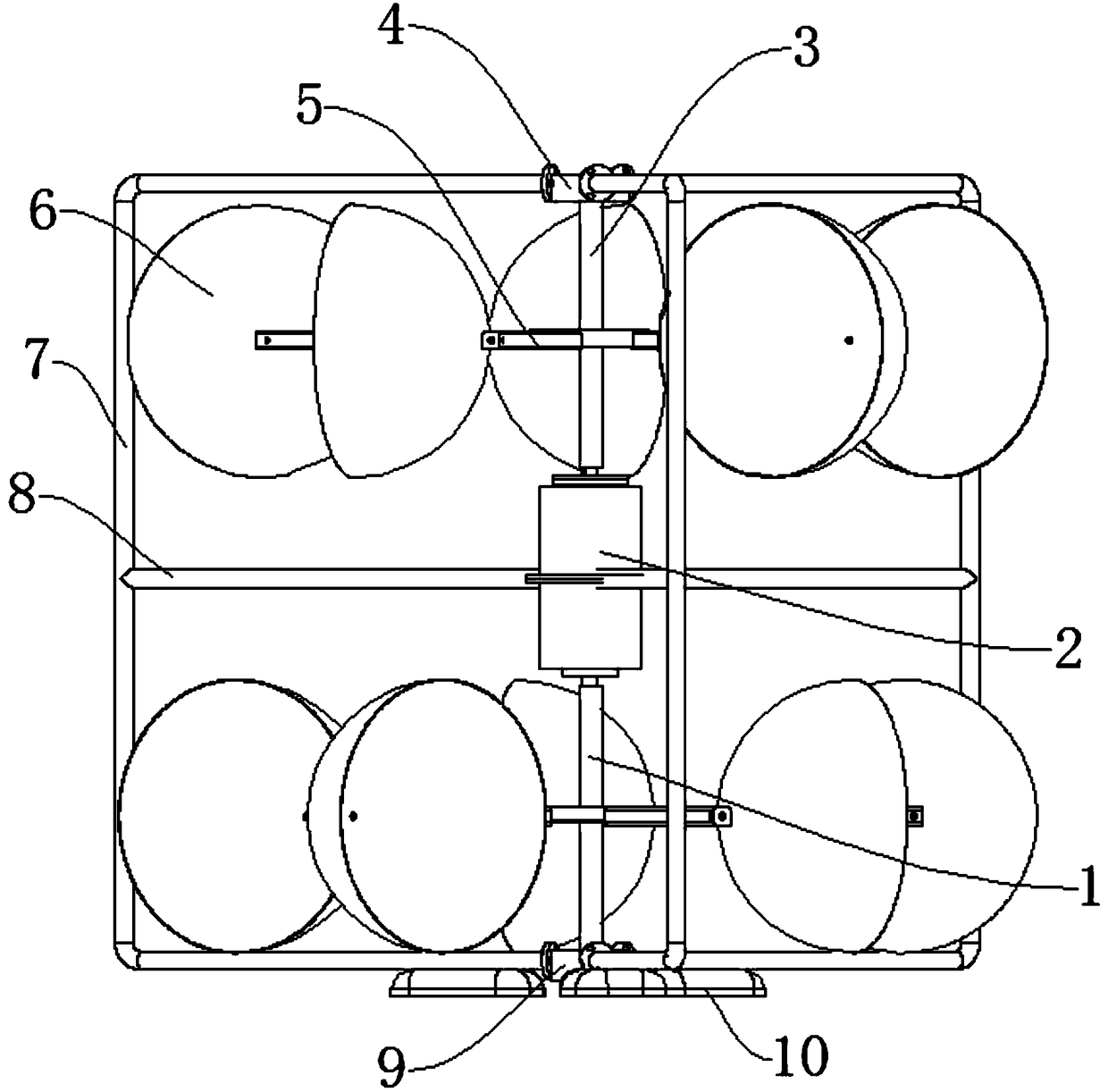

Rail wheel synchronous control device for traction power test device of rail transit vehicle

InactiveCN102945057ASame speedSame torqueRailway vehicle testingSimultaneous control of multiple variablesControl signalSynchronous control

The invention discloses a rail wheel synchronous control device for a traction power test device of a rail transit vehicle. An accompanying test motor is connected to one side of each rail wheel; a sensor is arranged between each rail wheel and an output shaft of each accompanying test motor; an accompanying test converter is connected to each accompanying test motor and is connected with a signal acquisition control unit arranged on the field; the signal acquisition control units are one or more circuit boards or circuit units arranged inside the accompanying test converters or signal acquisition controllers arranged outside the accompanying test converters; and the signal acquisition control units are used for receiving control signals from the sensors and / or other signal acquisition control units, and the control signals are integrally processed and then are outputted to the accompanying test converters. Dynamic work conditions of various motors are acquired on field in real time and are integrally processed by the signal acquisition control units for controlling various accompanying test converters, so that output rotating speeds and the torques of all motors can be enabled to be same, traction and brake work conditions of tested locomotives can be dynamically adapted and the synchronous control on the rail wheels can be realized more accurately.

Owner:北京鹏发欣光电力电子科技有限公司

Frictional type roller combining device

PendingCN109132324ACompact structureSimple installation and debuggingConveyor partsRoller-waysPulp and paper industry

Owner:苏州悦祺智能科技有限公司

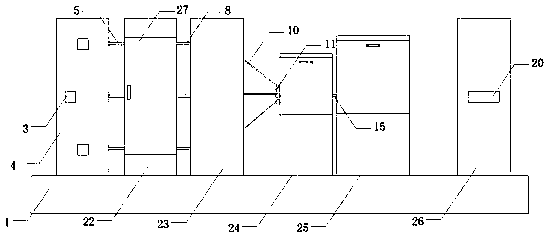

Die-cutting machine with composite function

PendingCN111361265ASimple processLabor savingLamination plant layoutLamination ancillary operationsElectric machineryManufacturing engineering

The invention belongs to the technical field of die-cutting machines, and concretely relates to a die-cutting machine with a composite function. The die-cutting machine comprises a base, the top wallof the base is sequentially connected with a feeding block, a gluing and drying block, a feeding block, a compounding block, a die cutting block and a collecting block from left to right. The front ends of three groups of rotating shafts I are connected with output shafts of motors I, the right wall of the feeding block is connected with the left wall of the gluing and drying block through three groups of connecting plates I, and the right wall of the gluing and drying block is connected with the left wall of the feeding block through three groups of connecting plates III. The die-cutting machine has the composite function, procedures are simplified, labor is saved, and working efficiency is improved; by adjusting the position of the rotating shafts I for placing the raw materials in the feeding block, the distances from the raw materials to the compounding block are equal, the effects that the moving speeds of the raw materials are synchronous and the raw materials are not misplaced to cause raw material waste during feeding are achieved, and the raw materials are better glued and dried during compounding through the gluing and drying device.

Owner:深圳市合联发实业有限公司

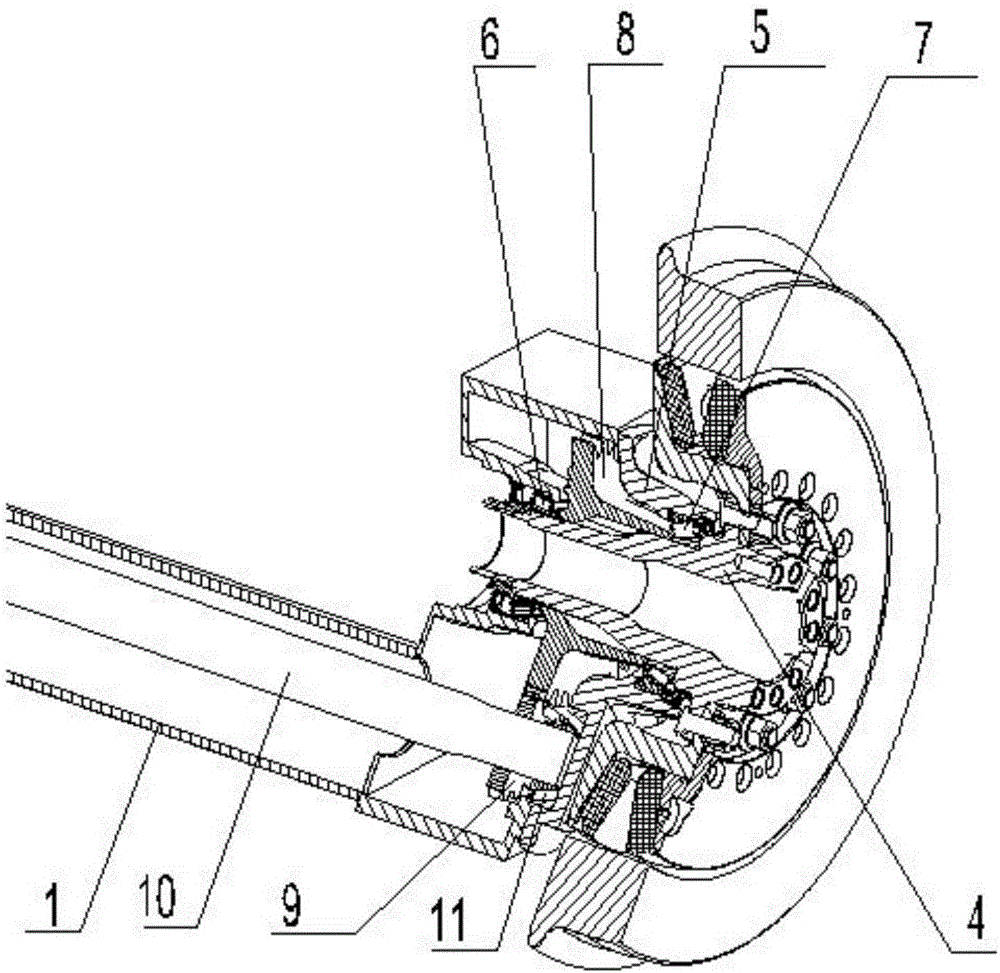

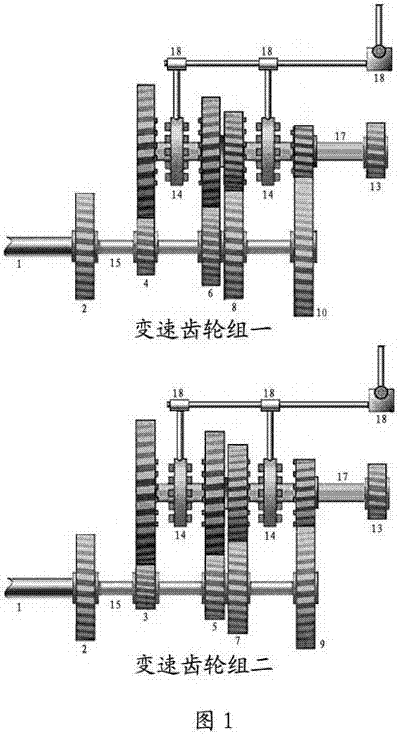

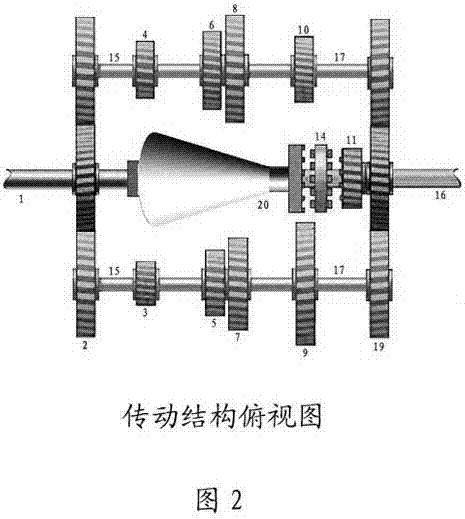

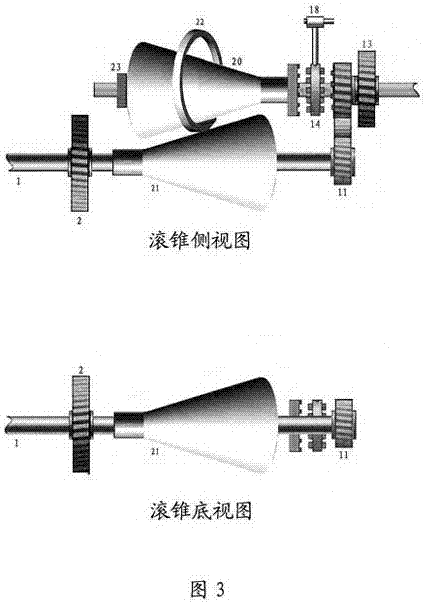

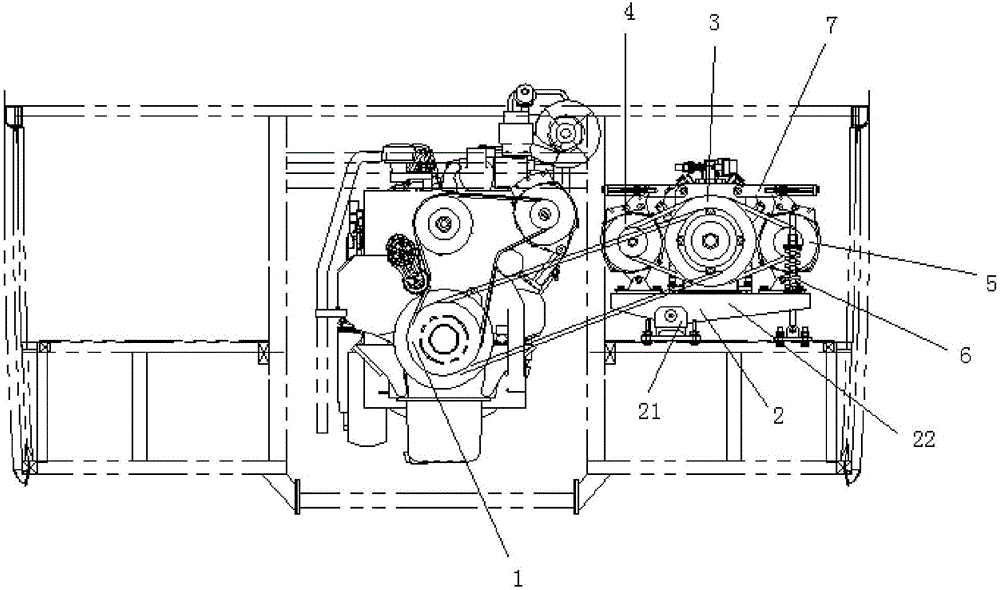

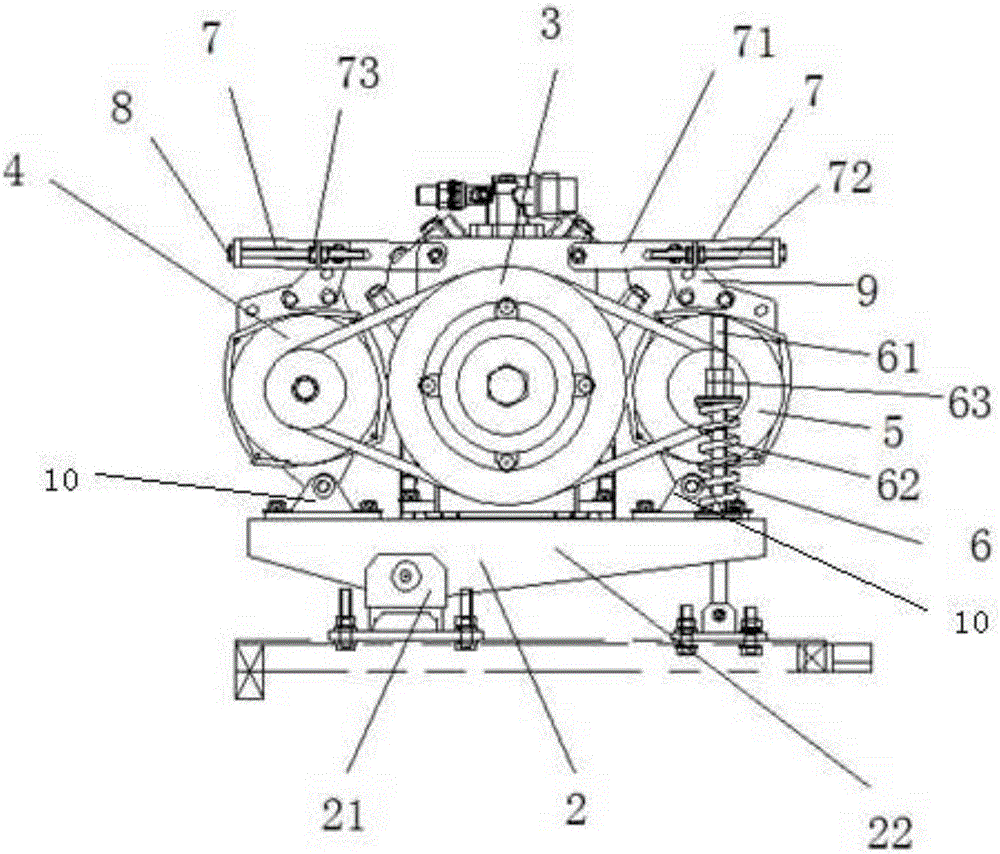

Gear and rolling cone compounded infinitely variable transmission

InactiveCN107401585ASpeed synchronizationThere will be no temporary interruption of powerToothed gearingsControl theoryFriction force

The invention relates to a compound infinitely variable transmission integrating gear engagement drive and rolling cone friction drive. Especially, gear synchronization and infinitely variable speed change are achieved by utilizing two rolling cone circumference faces and a friction force of an intermediate drive part, so that seamless butt joint of rotation speed synchronization and infinitely variable speed change is completed in the process of switching a separation state to an engaged state of a gear set. Due to the fact that gear engagement is completed by compounding the conical circumference faces, a spline shaft and a sleeve, a control mechanism for gear shifting is simplified, the transmission ingeniously integrates gear engagement drive and infinitely variable-speed frictional drive of a rolling cone together and has the advantages of smooth CVT drive, oil saving and DCT rapid gear shifting, and the drive efficiency is far higher than a frictionally driven CVT transmission. The gear and rolling cone compounded infinitely variable transmission is used for a speed changing device, the design and manufacturing of the speed changing device can be simplified, the power transmission efficiency and reliability of the transmission are improved, and the purposes of smoothness and oil saving are achieved.

Owner:舒健平

A power supply device for passenger cars

ActiveCN104626994BSpeed synchronizationAvoid failureGearingElectric powerFailure rateGenerating capacity

The invention discloses a complete coach power supply device which comprises an engine, a mounting support, a compressor, a first generator with a storage battery and a second generator with a storage battery. The mounting support comprises a base and a supporting frame, the base is fixed onto a coach framework, the supporting frame is rotatably connected with the base, the compressor and the first generator with the storage battery are mounted on the supporting frame, the compressor is in transmission connection with the engine through a belt, the second generator with the storage battery is mounted on the supporting frame, the first generator with the storage battery and the second generator with the storage battery are arranged on two sides of the compressor respectively, the first generator with the storage battery is in transmission connection with the second generator with the storage battery through a belt, and a vertical adjusting device for adjusting tension of the belt is mounted on the supporting frame. The complete coach power supply device is simple in structure, simple and convenient to mount, low in failure rate and cost and high in power generating capacity, and mounting spaces of the other parts of an engine bin are not occupied when the generators are mounted.

Owner:ANHUI ANKAI AUTOMOBILE

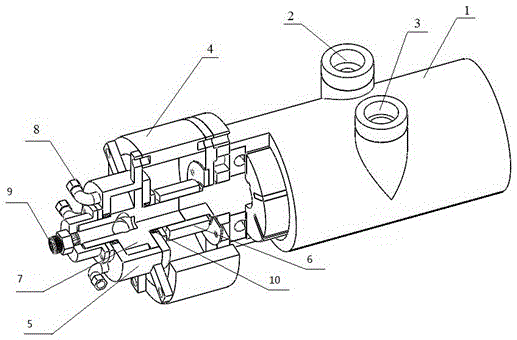

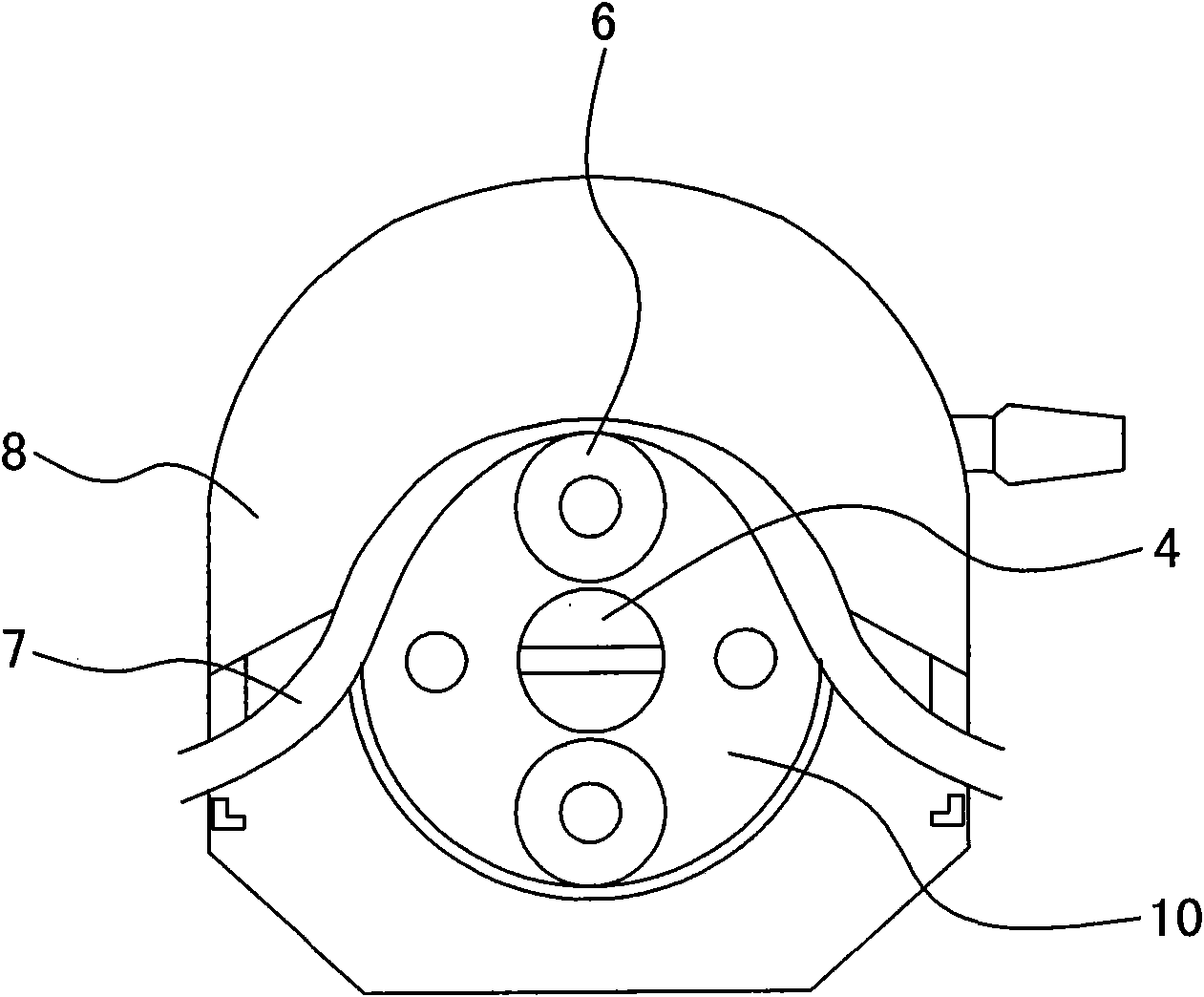

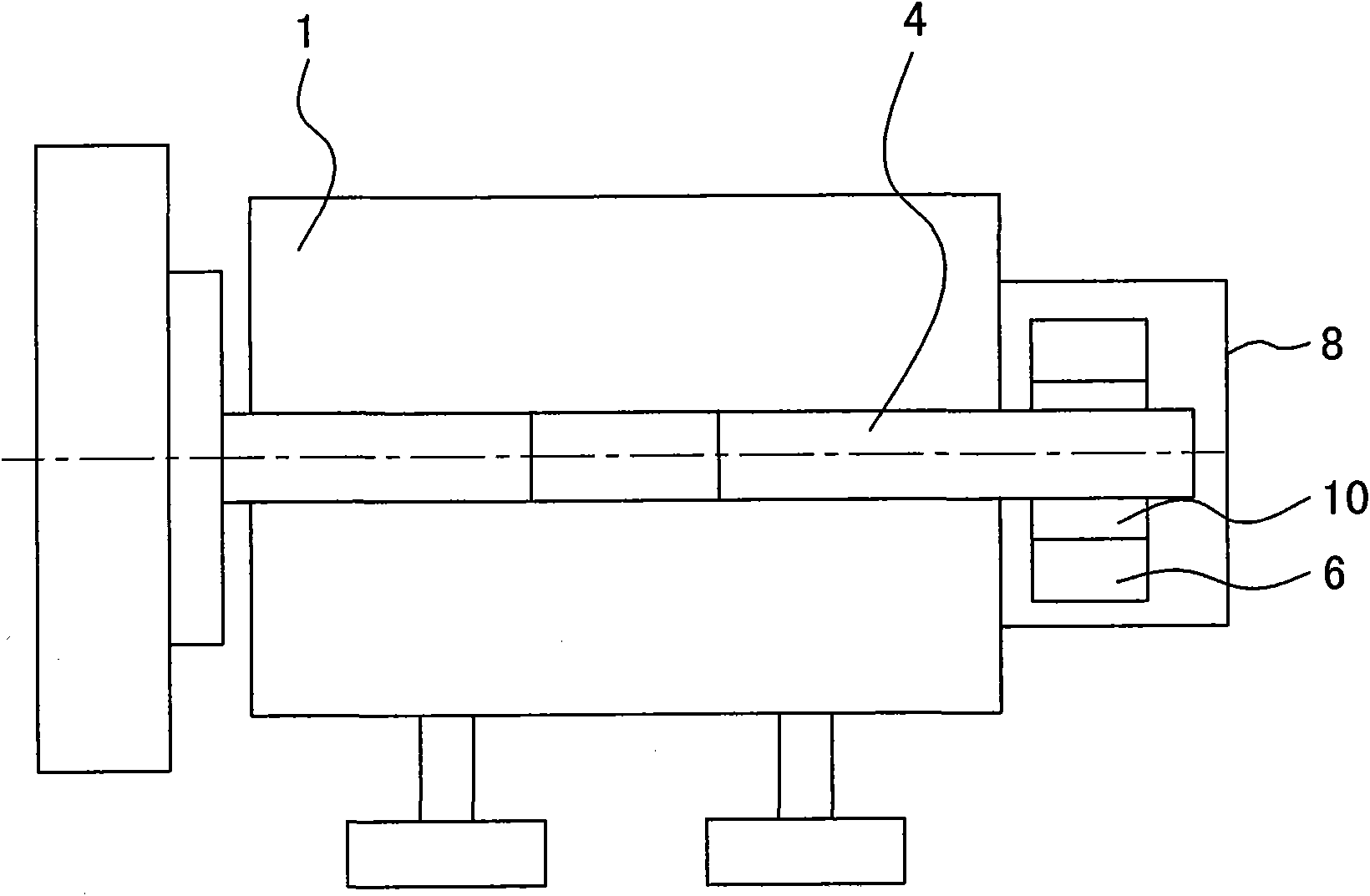

Variable-frequency multipath pulsating flow generation device

ActiveCN105065376AMultiplexedCan be superimposedFluid-pressure actuator componentsEngineeringPulsatile flow

The invention relates to a variable-frequency multipath pulsating flow generation device, and belongs to the technical field of fluid flow drive control engineering. The variable-frequency multipath pulsating flow generation device comprises a motor, a connection body, a semi-axis valve body, a sleeve, a semi-axis valve element and an end cover. The semi-axis valve body is arranged on the motor through the connection body. The semi-axis valve element is arranged in the semi-axis valve body. The end cover is arranged at one end of the semi-axis valve body. The other end of the semi-axis valve element is connected with the motor through the sleeve. By means of the variable-frequency multipath pulsating flow generation device, the pulsating flow of different asymmetric pulse widths can be controlled to be obtained, the multipath property and the superposition property are achieved, the difficulty that the pulsating flow can not be controlled does not exist, the requirements of engineering for different types of pulsating flow or fluid type pulsation signals can be met, and the engineering quality can be improved; the semi-axis valve element is connected with an output shaft of the motor through the sleeve, and therefore the rotation speed synchronization of the shaft can be achieved, and torque can be effectively transmitted; and the variable-frequency multipath pulsating flow generation device is simple in structure, easy to manufacture, easy and convenient to operate, easy to maintain, high in practicability and capable of avoiding resource waste and environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

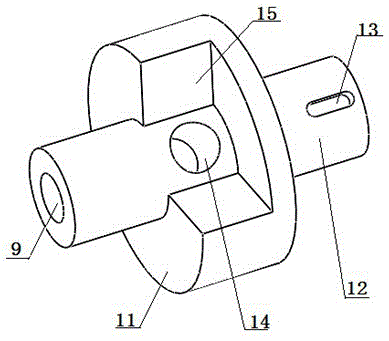

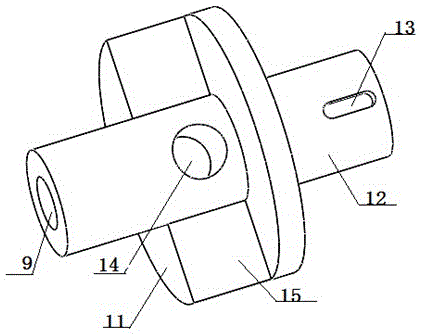

An agricultural compound clutch device

ActiveCN109812512BReduce shockSpeed synchronizationAgricultural machinesMechanical actuated clutchesAgricultural engineeringFlywheel

The invention discloses an agriculture combined type clutch device. The agriculture combined type clutch device comprises a clutch input shaft, a clutch output shaft, a driving tooth embedment disc, adriven tooth embedment disc, a driven disc, a friction plate and a clutch driving mechanism. The clutch input shaft is connected with a flywheel, and the flywheel is connected with a crankshaft of anengine. The clutch output shaft is connected with the input end of a speed changing box. The driving tooth embedment disc is connected with the clutch input shaft. The driven tooth embedment disc isarranged on the clutch output shaft in a sliding manner and engaged with the driving tooth embedment disc. The driven disc is arranged on the flywheel. The friction plate is opposite to the driven disc and is fixedly connected with the driven tooth embedment disc through a connecting device. The clutch driving mechanism is used for driving the driven tooth embedment disc to slide relative to the clutch output shaft so that the driving tooth embedment disc can be engaged with or separated from the driven tooth embedment disc and the friction plate can be in contact with or separated from the driven disc. By means of the agriculture combined type clutch device, the problems, such as temperature rise and abrasion, caused when the large-size dry type friction clutch is adopted are effectivelyreduced, and the slipping phenomenon cannot occur.

Owner:HUNAN AGRICULTURAL UNIV

Rail wheel synchronous control device for rail transit vehicle traction power test device

InactiveCN102945057BSame speedAvoid the defect of unequal torqueRailway vehicle testingSimultaneous control of multiple variablesSynchronous controlControl signal

Owner:北京鹏发欣光电力电子科技有限公司

Motor linear array synchronous bidirectional hybrid centrifugal damping wind power generation device

PendingCN109281799ASpeed synchronizationGenerating voltage is stableWind motor controlRenewable energy generationDamping constantDrive shaft

The invention discloses a motor linear array synchronous bidirectional hybrid centrifugal damping wind power generation device. The wind power generation device comprises a generator unit. The upper and lower sides of the generator unit are coaxially provided with an upper transmission shaft and a lower transmission shaft correspondingly. The upper end of the upper transmission shaft is rotatablyarranged in an upper bearing block. Thelower end of the lower transmission shaft is rotatably arranged in a lower bearing block. The upper bearing block and the lower bearing block are fixedly connected through a plurality of supporting frames. The supporting frames and the generator unit are fixedly connected through connecting rods. The upper transmission shaft and the lower transmission shaft are provided with a plurality of blade arms. The blade arms are fixedly provided with blades. The blades on the lower transmission shaft and the blades on the upper transmission shaft are opposite inorientation. The wind power generation device is higher in wind power generation efficiency. The rotating speed of generators are limited by self-damping constant-speed rotation. The service life of thegenerator is longer. The rotating speeds of the two generators are synchronous. The output voltage is more stable.

Owner:刘春梅

Dual paving and flattening device

A double pavement and leveling device includes toothed rollers. Bearing housings are installed at both ends of the toothed rollers. Tooth plates are provided on the side surfaces of the two ends of the toothed rollers. The toothed rollers and the tooth plates are connected and fixed by hexagon socket screws. There are two toothed rollers, and the two toothed rollers are connected with a speed reducer. The toothed roller is formed by welding a shaft and a steel pipe. The invention is a double paving and leveling device, which solves the problems of uneven graphite paving and non-aggregation, and ensures the qualified rate of graphite paper in the later production process.

Fire hose testing machine

ActiveCN103487344BReduce work intensityImprove test reliabilityMaterial strength using tensile/compressive forcesInvestigating machinabilityElectricitySynchronous motor

Owner:济南康和消防技术有限公司

Control method, control device, storage medium and processor of egg roll machine

ActiveCN111488021BImprove pass rateImprove stabilityMultiple dynamo-motor startersMultiple dynamo-electric motors speed regulationElectric machineryMachine

The present application provides a control method, a control device, a storage medium and a processor of an egg roll machine. The control method includes: obtaining a first rotation speed, a second rotation speed, and a third rotation speed. The first rotation speed is the rotation speed of the baking plate servo motor, the second rotation speed The second rotating speed is the rotating speed of the roller rotating motor, and the third rotating speed is the rotating speed of the lifting motor; determine whether the first ratio, the second ratio and the third ratio are all equal, and the first ratio is the ratio of the first rotating speed to the first predetermined rotating speed, The second ratio is the ratio of the second rotation speed to the second predetermined rotation speed, and the third ratio is the ratio of the third rotation speed to the third predetermined rotation speed; any two of the first ratio, the second ratio and the third ratio are not equal In this case, adjust the first rotation speed, the second rotation speed and the third rotation speed so that the first ratio, the second ratio and the third ratio are all equal, so that the rotation speed of the baking plate servo motor, the rotation speed of the roller rotation motor and the The speed of the lifting motor is kept synchronized, which improves the qualified rate of egg rolls.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Mechanical creepage-type chemical mixing device used for atomizing machine

InactiveCN102107161AExposure hazard reductionReduce spray labor intensityLiquid spraying apparatusPlunger pumpEngineering

The invention relates to a mechanical creepage-type chemical mixing device used for an atomizing machine, which comprises a plunger pump, wherein the plunger pump is provided with a water inlet and a water outlet, the water inlet is connected with a water container, the water outlet is connected with a spray gun component, and a plunger of the plunger pump is driven by the power of a plunger crankshaft. The mechanical creepage-type chemical mixing device is characterized in that a cam is arranged at the other end of the plunger crankshaft, more than one roller-shaped press roller is embedded in the cam, a housing is mounted outside the press roller, a creepage pipe is arranged between the housing and the press roller, the creepage pipe is compressed on the inner wall of the housing when the press roller rolls, and one end of the creepage pipe is connected with a pesticide mother liquid container and the other end thereof is connected with the water inlet of the plunger pump. According to the technical scheme, the plunger crankshaft and the roller-shaped press roller mounted on the cam are coaxially driven by the same one power force, so that the flow rate of the plunger pump and the flow rate of the creepage pipe are increased or reduced at the same time, which can achieve the effect of dynamically mixing the chemicals at a constant proportion and ensure that the whole atomizing machine can mix the chemicals at an accurate proportion and spray the chemical mixture. The mechanical creepage-type chemical mixing device used for the atomizing machine has significant progresses and positive results.

Owner:林夏满 +2

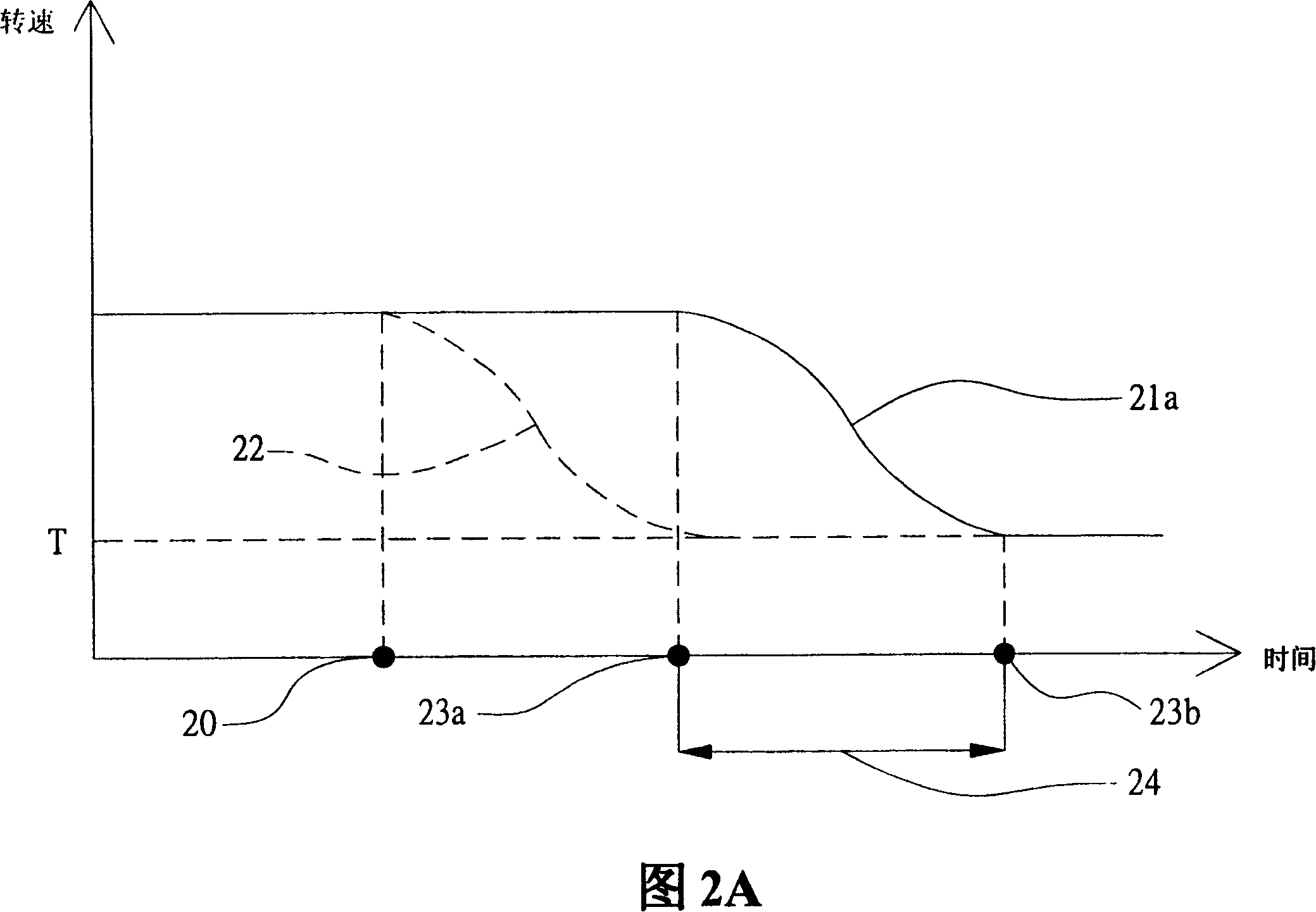

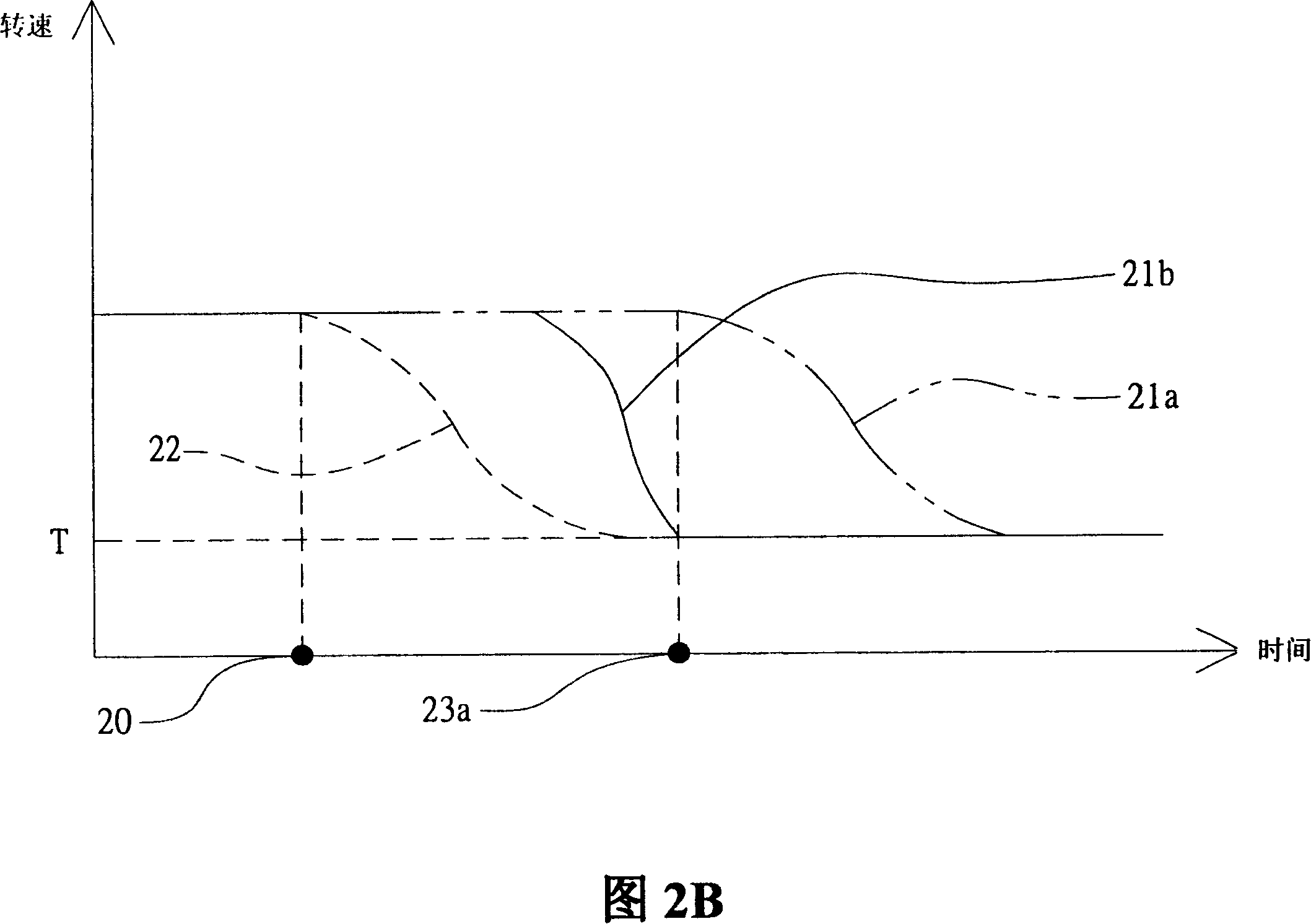

Gearshift control method of gear type gearbox in composite motor vehicle

A method for shifting gear of gear box on composite power vehicle utilizes motor to control combustion engine rotating speed for making it be synchronization to input shaft rotating speed of gear box to let clutch be engaged smoothly and quickly so as to decrease wear-out of clutch disc and reduce time of gear-shift when gear is shifted.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com