Motor linear array synchronous bidirectional hybrid centrifugal damping wind power generation device

A technology of wind power generation device and linear array, which is applied to wind turbines, wind turbines, and combinations of wind turbines at right angles to the wind direction, can solve the problems of unstable power generation, waste of energy consumption, abandoned wind, etc., and achieve stable power generation voltage, Easy to observe and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

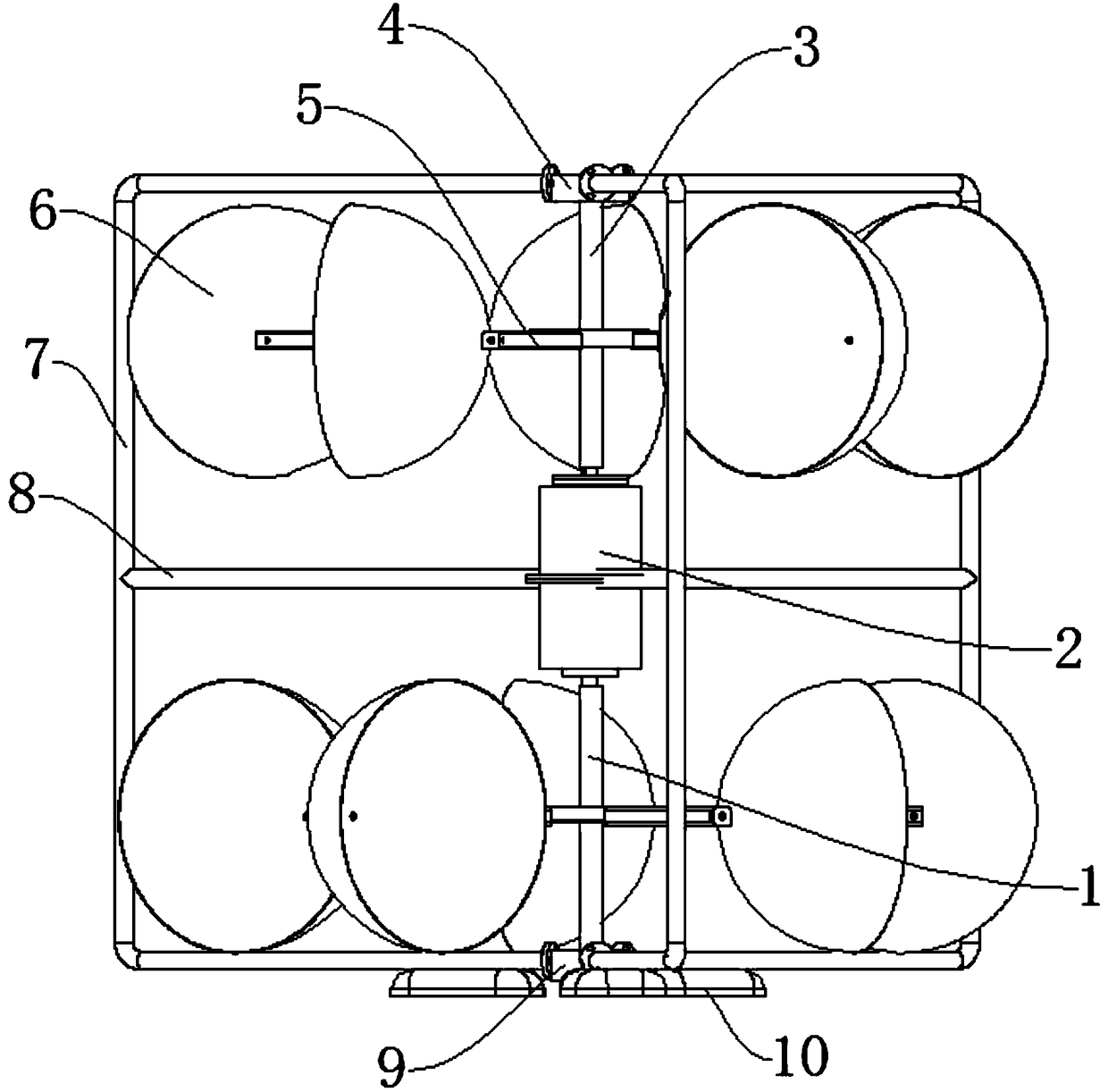

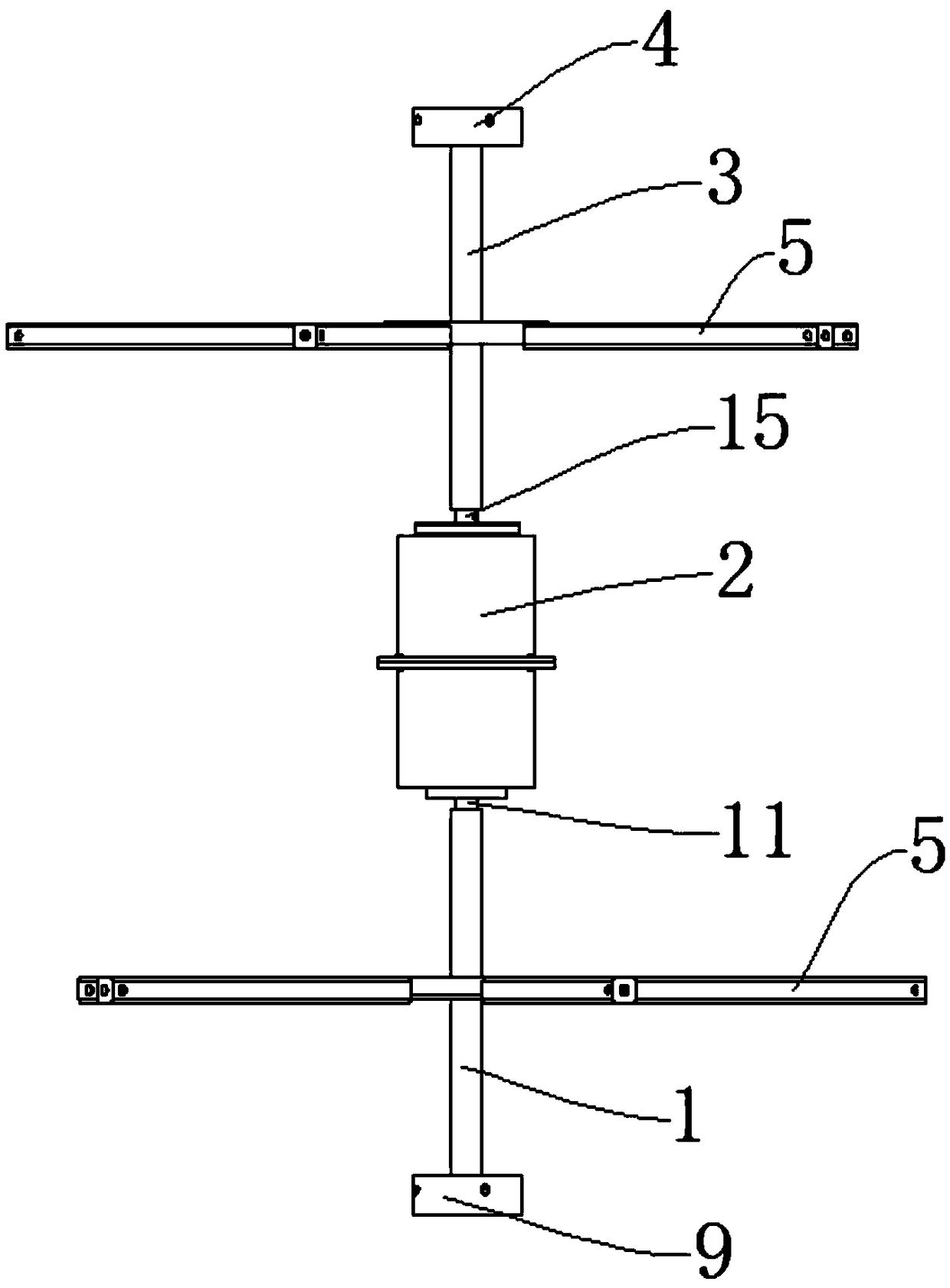

[0032] like Figure 1-Figure 4 As shown, the motor linear array synchronous two-way compound dynamic centrifugal damping wind power generation device includes a vertically arranged power generation group 2. The upper and lower sides of the power generation group 2 are coaxially provided with an upper transmission shaft 3 and a lower transmission shaft 1. The upper transmission shaft 3 The upper end is rotatably arranged in the upper bearing seat 4, and the lower end of the lower transmission shaft 1 is rotatably arranged in the lower bearing seat 9. The upper bearing seat 4 and the lower bearing seat 9 are fixedly connected by four supporting frames 7, and between the supporting frame 7 and the generator set 2 Through the fixed connection of the connecting rod 8, the setting of the connecting rod 8 can improve the stability of the coaxial fixed housing 17 of the motor, and at the same time facilitate the line connection between the upper generator 16 and the lower generator 20,...

Embodiment 2

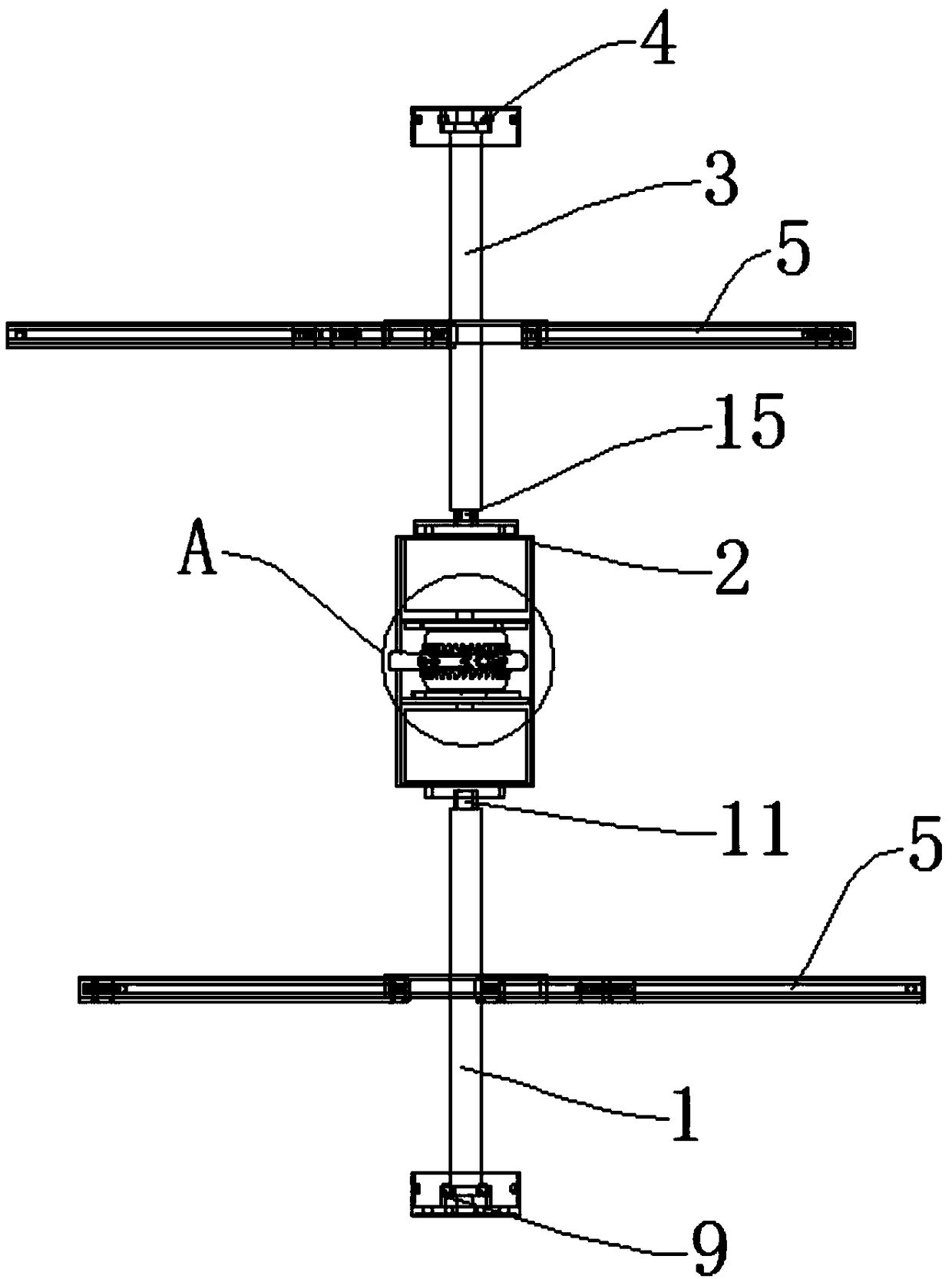

[0042] like Figure 5 As shown, Embodiment 2 is an improvement on the basis of Embodiment 1. The upper centrifugal damping body 14 includes a centrifugal damping disc 21, which is fixedly connected to the upper rotating shaft 15. The centrifugal damping disc 21 is rotatably connected with a number of centrifugal dampers. The hoof 24, the rotating shaft of the centrifugal damping hoof 24 is eccentrically arranged with the centrifugal damping disc 21, and the side of the centrifugal damping body facing the center of the centrifugal damping disc 21 is fixedly connected with a tension spring 22, and the other end of the tension spring 22 is connected near the center of the centrifugal damping disc 21 The structure of the lower centrifugal damping body 19 is the same as that of the upper centrifugal damping body 14 , and the centrifugal damping disc 21 of the lower centrifugal damping body 19 is fixedly connected with the lower rotating shaft 11 .

[0043] The upper centrifugal dam...

Embodiment 3

[0046] like figure 1 As shown, Embodiment 3 is improved on the basis of Embodiment 2, and a lamp box 10 is fixedly installed at the bottom of the support frame 7 .

[0047] The arrangement of the light box 10 enables the power generating device to have a lighting effect, and at the same time facilitates the observation of the working conditions of the power generating set 2 at night.

[0048] The remaining structures and working principles of Embodiment 3 are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com