Dual paving and flattening device

A flat and double technology, applied in the direction of presses, presses, manufacturing tools, etc. using rotating pressure components, can solve the problems of non-aggregate, uneven graphite paving, etc., and achieve the effect of simple material acquisition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

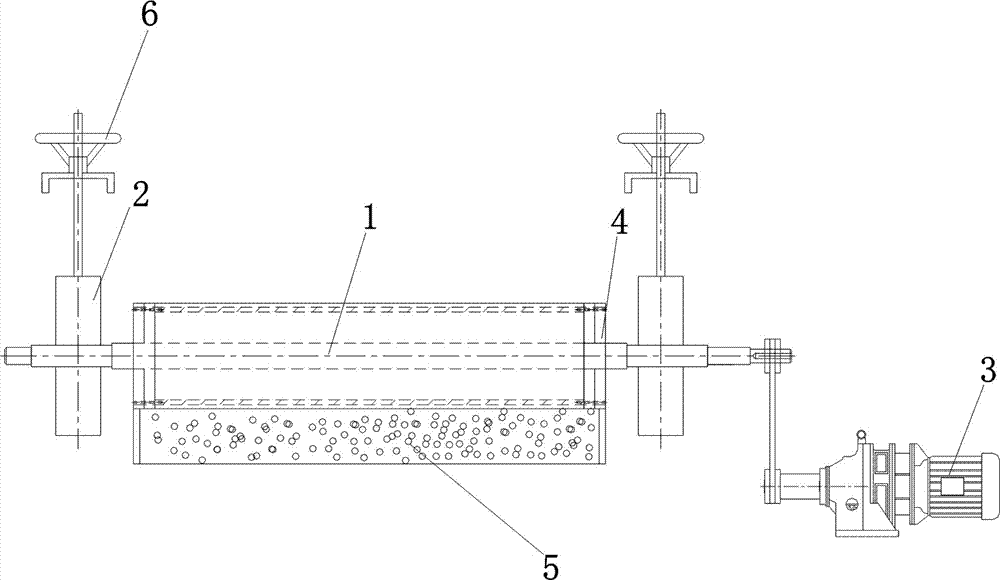

[0019] Such as figure 1 As shown, a double pavement and leveling device includes a toothed roller 1. Bearing housings 2 are installed at both ends of the toothed roller 1. Toothed rollers 1 are provided with toothed plates 4 on the sides of the two ends. The toothed rollers 1 and the toothed plates 4 is connected and fixed by hexagon socket head screws.

[0020] Described gear roller 1 is formed by welding of 45# axle, 45# steel pipe, and transmission mechanism selects the transmission device in the prior art for use. There are two toothed rollers 1, and the two toothed rollers 1 are connected to a speed reducer 3.

[0021] The needle teeth of the toothed roller 1 are processed by a numerical control milling machine, and the needle teeth of the toothed roller 1 form a certain angle. The precision between each pin tooth is basically the same, and the angle of the pin tooth is small. The angle is between 15° and 45°.

[0022] The bearing seat 2 is provided with a hand wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com