Die-cutting machine with composite function

A composite function, die-cutting machine technology, applied in the lamination device, lamination auxiliary operation, lamination system, etc., can solve the problems of waste of raw materials, misalignment of raw materials, and reduced work efficiency, so as to improve work efficiency and speed of raw materials Synchronous, even gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

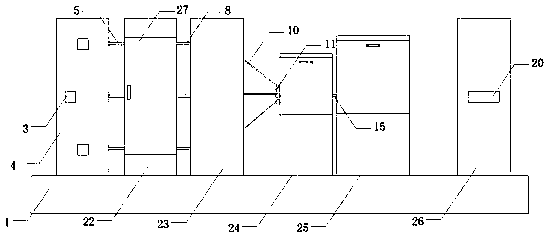

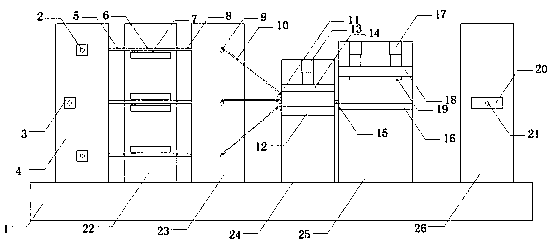

[0021] see Figure 1-3 , the present invention provides a technical solution:

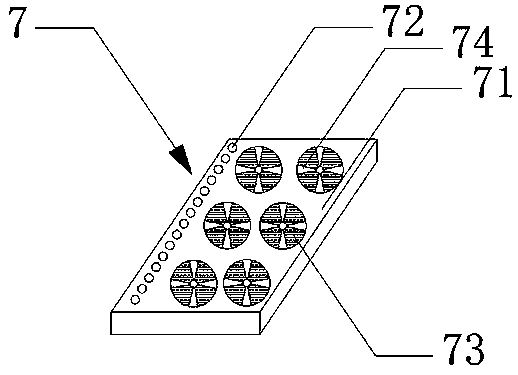

[0022] A die-cutting machine with composite functions, comprising a base 1, the top wall of the base 1 is sequentially connected from left to right with a feeding block 4, a glue drying block 22, a feeding block 23, a compound block 24, a mold Cutting block 25 and material receiving block 26, three groups of rotating shafts 12 are arranged on the inner cavity of feeding block 4, and three motors 13 are arranged on the front wall of feeding block 4, and three motors 13 are respectively connected with three groups of The rotating shaft 12 is connected by a coupling, the right wall of the feeding block 4 is connected with the left wall of the gluing drying block 22 through three sets of connecting plates 5, the right wall of the gluing drying block 22 is connected with the left wall of the feeding block 23 The walls are connected by three sets of connecting plates 38, and the inner cavity of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com