Brake master cylinders with contoured pressure pistons for motor vehicle braking systems

A technology for brake master cylinders and pressure pistons, which is applied in the direction of brake transmission devices, fluid pressure actuators, hydraulic brake transmission devices, etc., and can solve the problem of weakening of the internal throttling effect, leakage of the sealing mechanism 1, radial Hole 8 is completely closed and extended, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

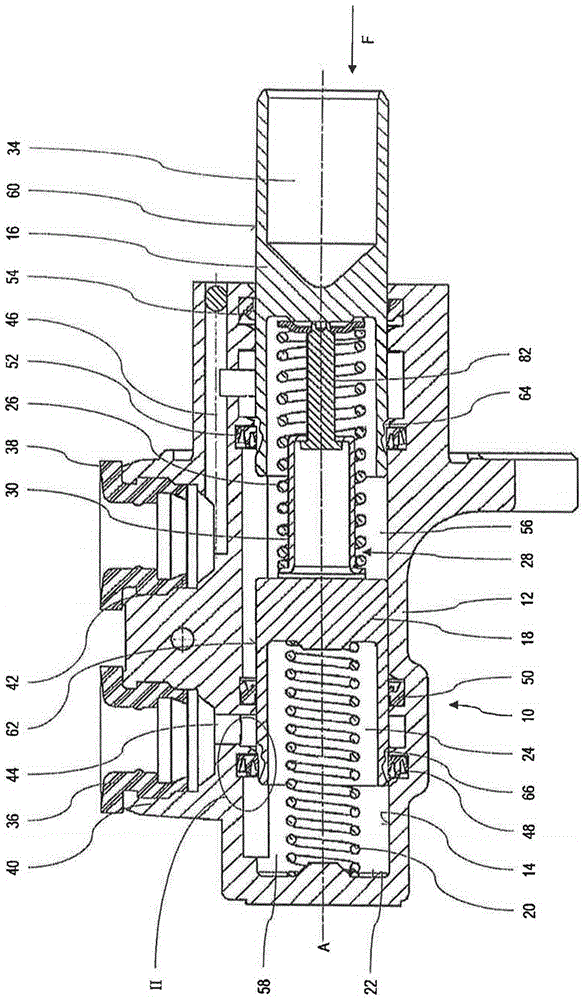

[0026] figure 1A brake master cylinder arrangement according to the invention, generally designated with the reference numeral 10 , is shown in a cross-sectional view including the axis. The master cylinder arrangement 10 has a master cylinder housing 12 in which a substantially cylindrical recess 14 is arranged. Two pressure pistons are guided in this cylindrical recess 14 , that is to say a first pressure piston, the so-called primary piston 16 , and a second pressure piston, the so-called secondary piston 18 . The secondary piston 18 is supported via a return spring 20 on the bottom surface 22 of the master cylinder housing 12 . The other end of the return spring 20 facing away from the base 22 is supported in a recess 24 in the secondary piston 18 . Likewise, the primary piston 16 is supported on the secondary piston 18 via a return spring 26 . The return spring 26 is prestressed by means of a tensioning mechanism 28 which has a cup 30 and a plunger 32 . The main pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com