Casting mold with heat sink molding cavity

A radiator and molding cavity technology, applied in the field of casting molds, can solve the problems of low positioning accuracy, low casting accuracy, wrong box defects, etc., and achieve high dimensional accuracy, high mold clamping accuracy, and good casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further elaborated below according to the drawings and specific embodiments of the specification.

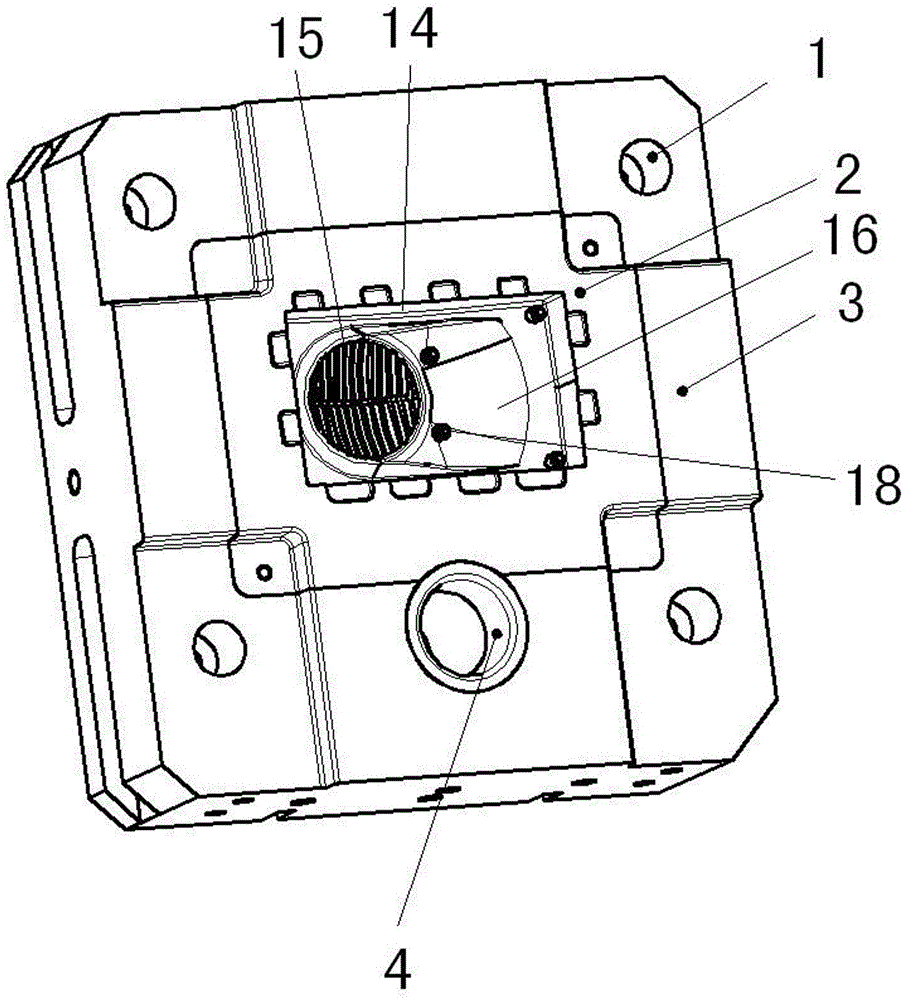

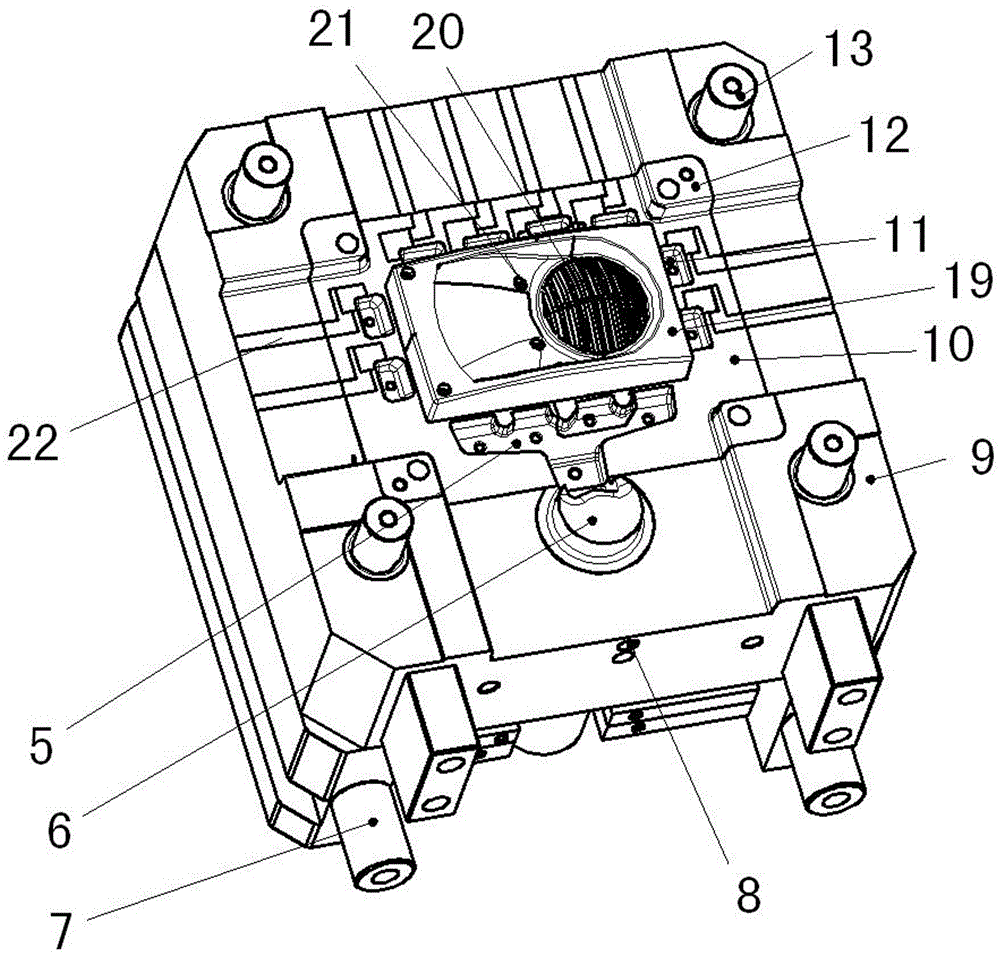

[0011] In the figure, 1 is the guide sleeve, 2 is the fixed mold core, 3 is the fixed mold frame, 4 is the sprue sleeve, 5 is the runner, 6 is the shunt, 7 is the anti-collision column, 8 is the cooling water channel, and 9 is the movable mold Frame, 10 is the movable mold core, 11 is the slag bag, 12 is the fine positioning bump, 13 is the guide post, 14 is the fixed mold cavity, 15 is the circular radiator forming boss, 16 is the slope, 18 is the cylindrical pin 19 is a rectangular boss, 20 is a radiator forming cavity, 21 is a circular groove, 22 is an exhaust groove, and 23 is a slag bag groove.

[0012] A casting mold with a radiator molding cavity, comprising a fixed mold frame 3, a fixed mold core 2, a movable mold frame 9 and a movable mold core 10, characterized in that the fixed mold frame 3 is provided with a guide sleeve 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com