Contactless full-automatic quantitative filling machine and filling method thereof

A fully automatic, non-contact technology, used in barrel/cask filling, liquid filling, etc., can solve the problems of inability to quantify the filling valve, short equipment life, frequent overflow, etc., to avoid ozone corrosion, shorten life, and improve moisture. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

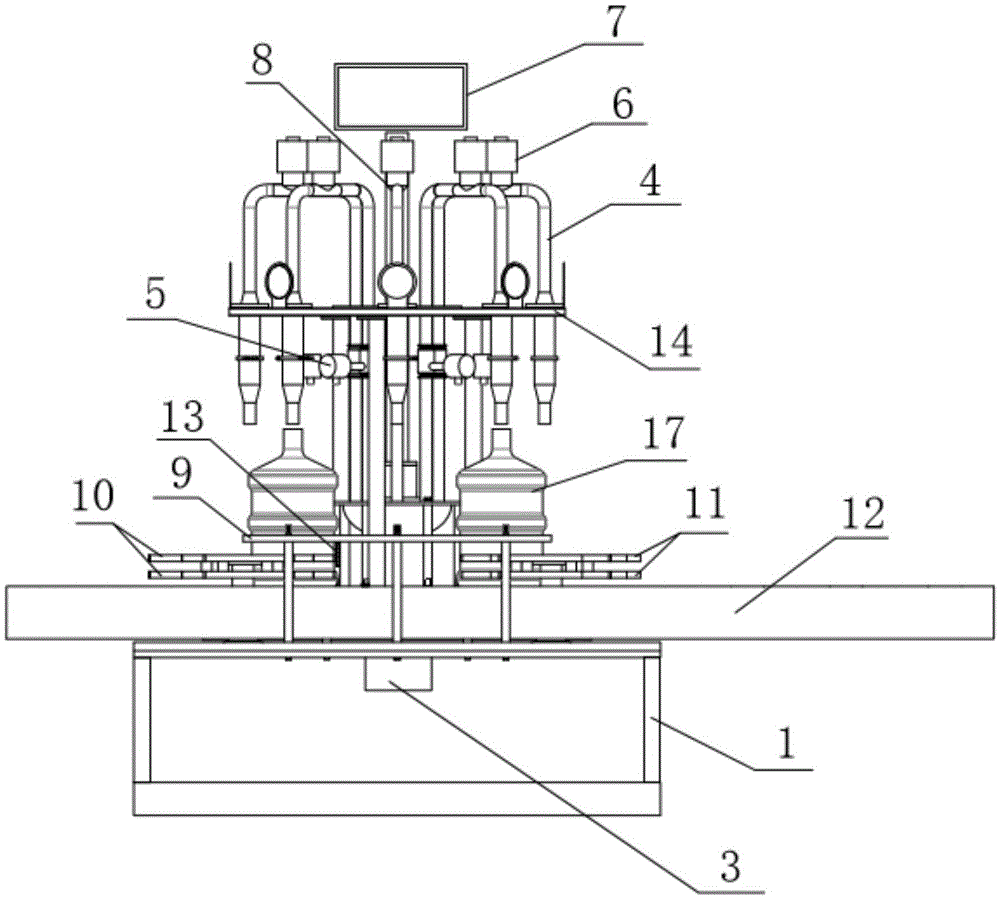

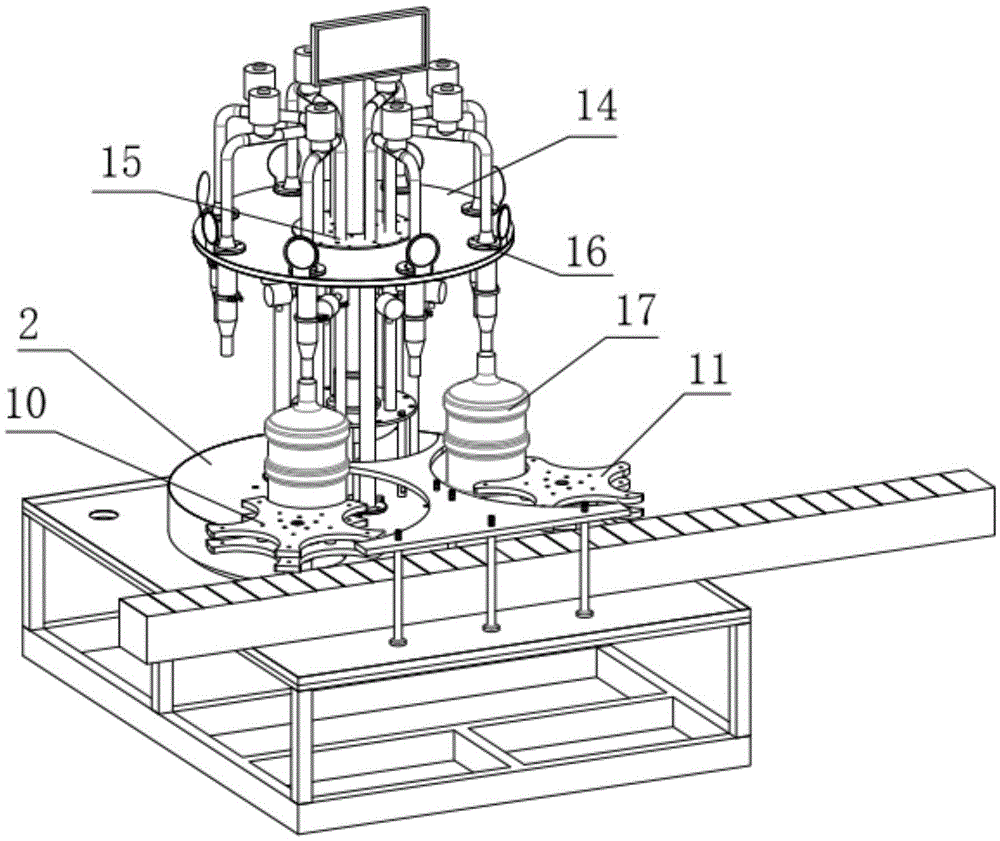

[0016] Such as figure 1 and figure 2 As shown, a non-contact automatic quantitative filling machine includes a bracket 1, which also includes a rotating disk 2, a motor 3, a plurality of filling pipes 4, a flow meter 5, a solenoid valve 6, a microcomputer 7, and a barrel guard 9. Bucket-in positioning star wheel 10, barrel-out positioning star wheel 11, conveyor chain 12, electronic eye sensor 13 and positioning disc 14, the rotating disc 2 is installed on the support 1, and the motor 3 is installed on the support 1 and located on the rotating disc 2, the output shaft of the motor 3 is connected to the rotating shaft of the rotary disk 2, and a plurality of filling pipes 4 are installed on the bracket 1 and extend from the middle of the rotary disk 2, and the water inlet of each filling pipe 4 A flow meter 5 is partially installed, and a solenoid valve 6 is installed on the water outlet part of each filling pipe. On the positioning plate 14, an inlet hole 15 is evenly opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com