Cutting liquid purifying treatment device

A technology of purification treatment and cutting fluid, applied in the direction of lubricating composition, etc., can solve the problems of poor deodorization effect, high cost, and affecting production and operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

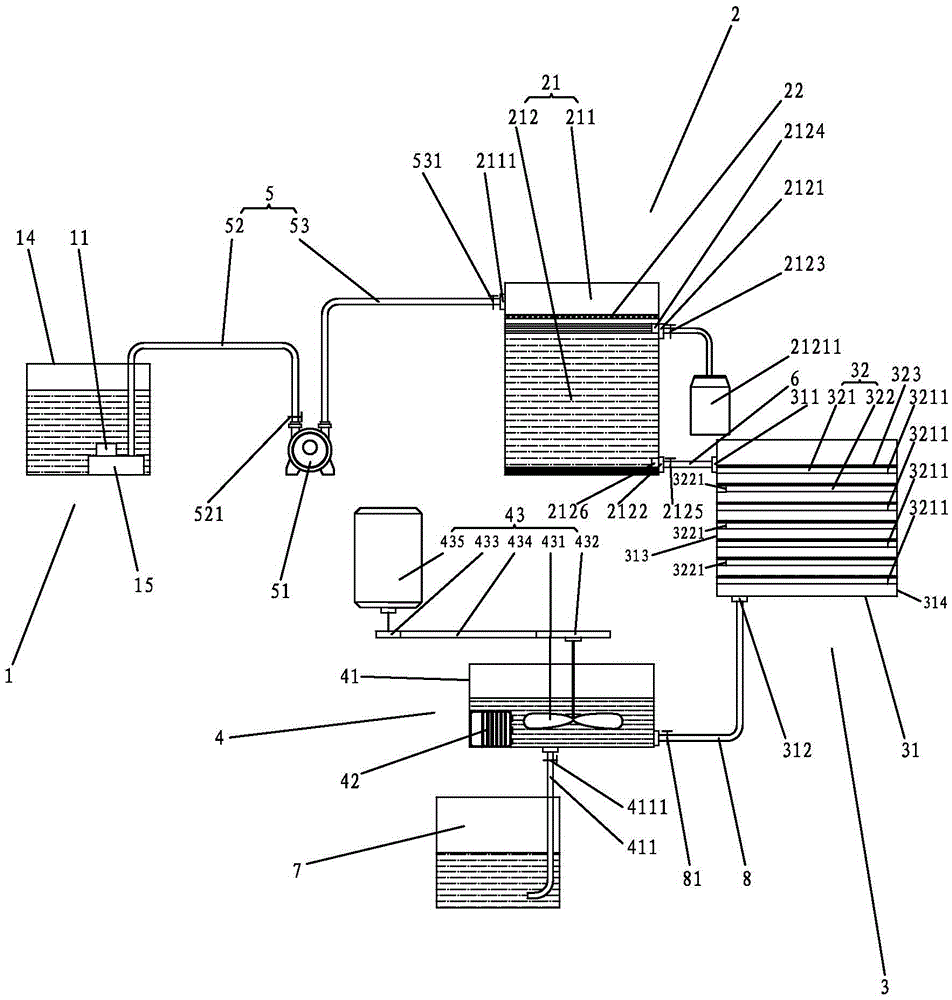

[0046] A cutting fluid purification treatment device of the present invention, such as Figure 1-4 As shown, the purification process includes a screen filter device 1, a gravity separation device 2, an impurity precipitation device 3 and a deodorization device 4 in sequence.

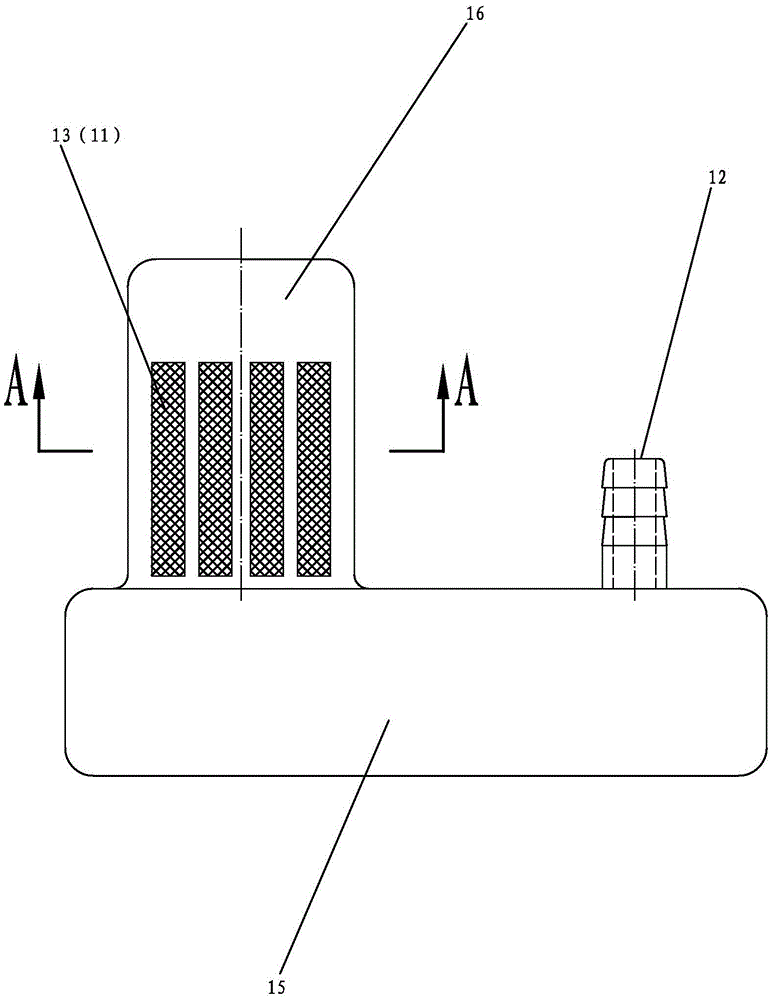

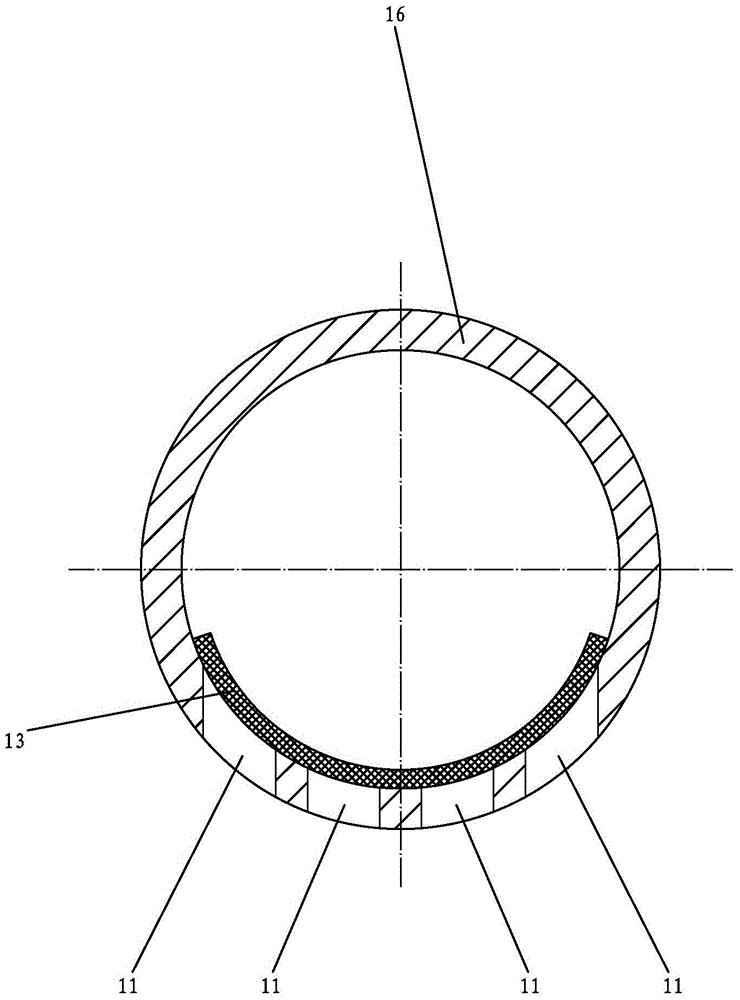

[0047] The mesh filter device 1 has a first oil inlet 11 and a first oil outlet 12, and the mesh size of the filter 13 of the mesh filter device 1 (maximum pore width, equivalent to the diameter of a circular hole) is less than 12 microns. The gravity separation device 2 comprises a first containing body 21 and a fine filter screen 22 arranged in the first containing body 21, and the fine filter screen 22 is arranged in the first containing body 21 and divides the first containing body 21 into upper The containing part 211 and the lower containing part 212 be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com