Box-type tempering furnace, tempering furnace conveying system and tempering furnace control method

A technology of conveying system and tempering furnace, which is applied in the field of heat treatment, can solve the problems of inconsistent product quality, low provisioning utilization rate, and low work efficiency, and achieve the effects of consistent product quality, high provisioning utilization rate, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

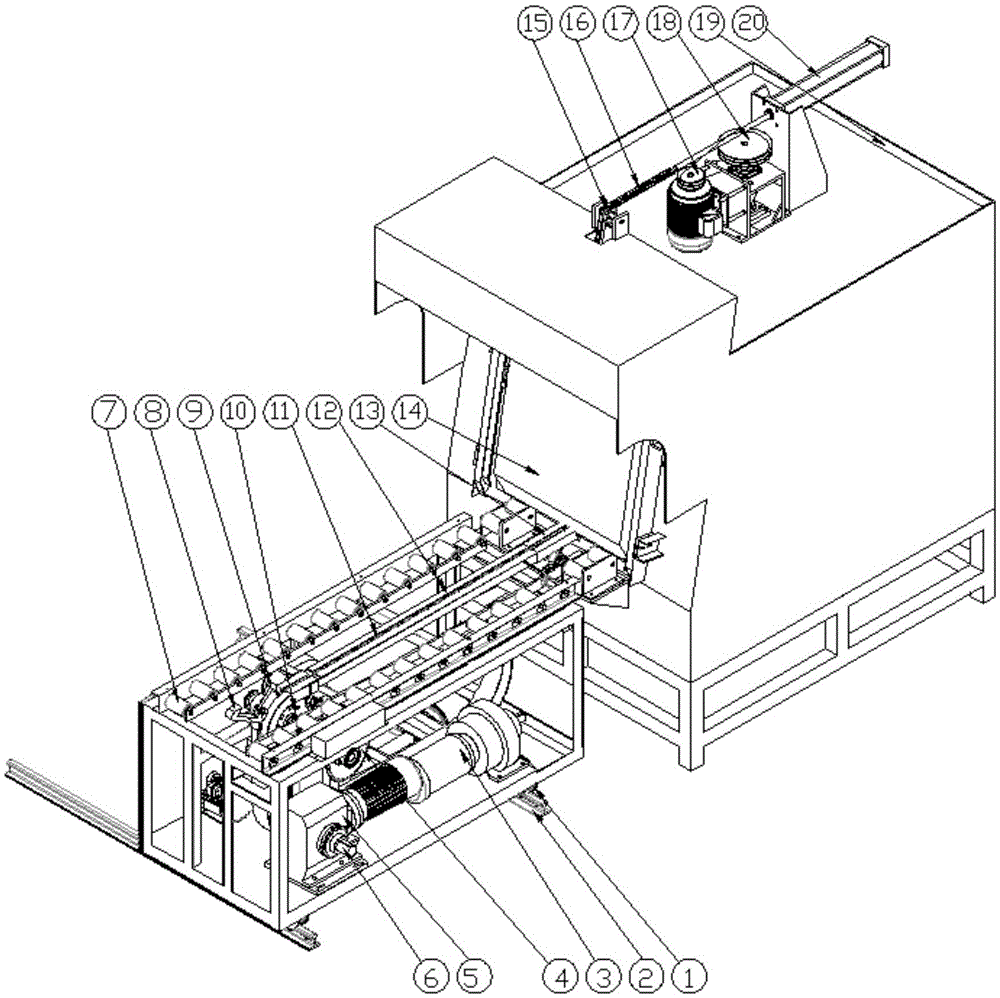

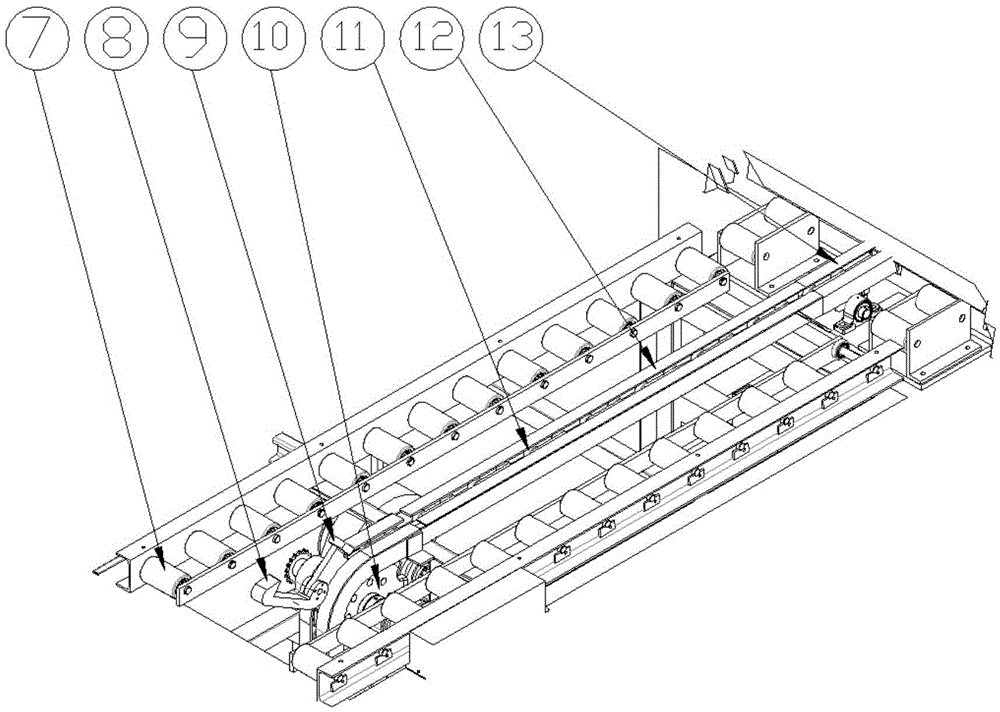

[0047] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a tempering furnace conveying system includes a conveying track 1, a conveying frame and a feeding system. There are two conveying rails 1, which are arranged in parallel on the front side of the tempering furnace. The conveying frame includes a frame body, a frame body Two sets of conveying wheels 2 are arranged at the bottom, and the conveying wheels 2 cooperate with the conveying track 1. The lower part of the frame is provided with a reciprocating deceleration motor 3 and a feeding decelerating motor 5. The reciprocating decelerating motor 3 drives the conveying wheels 2 to move, and the feeding decelerating motor 5 passes through the transmission Small sprocket 6 drives the transmission large sprocket 4 that frame body top is provided with, and transmission large sprocket 4 drives the work of feeding system, and described reciprocating reduction motor 3 and feeding reduction motor 5 are connected with ext...

Embodiment 2

[0051] like figure 1 , figure 2 As shown, based on the box-type tempering furnace of the tempering furnace conveying system of embodiment 1, several rollers 7 on both sides of the upper part of the frame body, 25 rollers are arranged on each side on both sides, and each spacing is 40mm; small spacing can transmit heating Parts are smaller, also include casing 19, furnace door 14, temperature control table, be provided with stirring blade in the tempering furnace, the setting of stirring blade ensures that the temperature in the tempering furnace is consistent and even when heating.

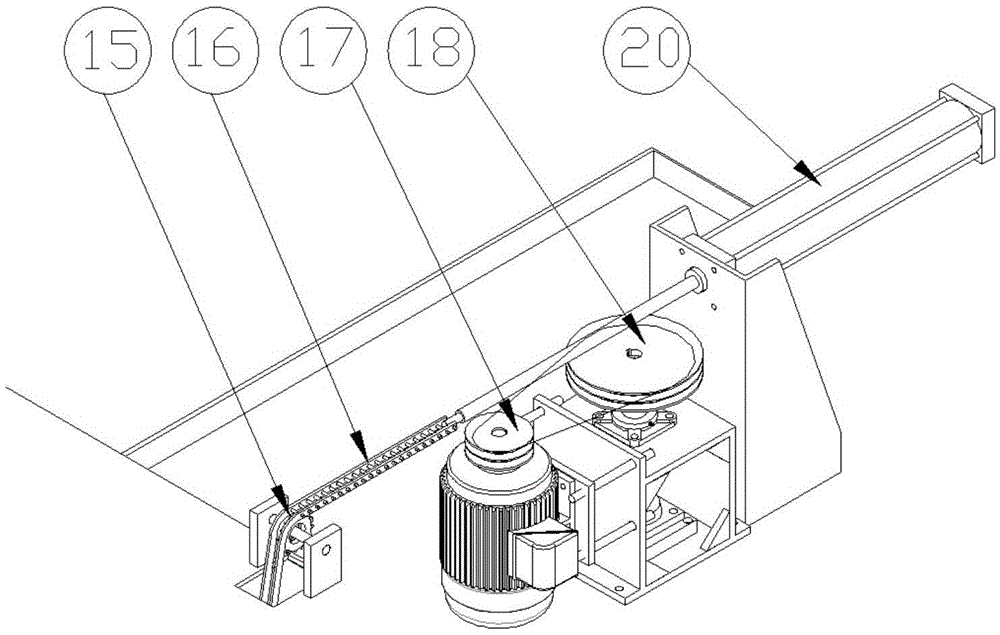

[0052] The top of the box body 19 is provided with a furnace door sprocket 15, a furnace door chain 16 connected to the furnace door 14, a furnace door motor 17 and a pulley 18 for driving the furnace door chain 16, and a door opening and closing cylinder 20 connected to the end of the furnace door chain 16. , the door opening and closing cylinder 20 and the furnace door motor 17 are connected w...

Embodiment 3

[0054] A method for controlling a box-type tempering furnace based on embodiment 2, the steps are as follows:

[0055] 1) Turn on the power, and the temperature control meter will display the temperature value in the heating zone;

[0056] 2) Determine the required tempering temperature by setting the temperature control table of the control system; set it to 550 degrees, and the stress removal effect can reach the best state when the temperature is tempered at 550 degrees;

[0057] 3), turn on the heating switch and start to heat up, the heating indicator light is on, and the temperature control meter starts heating along the set temperature curve; the tempering furnace is provided with an alarm and an alarm indicator light. This place is set to output an alarm when the temperature exceeds 5°C, and the alarm indicator light indicates that the alarm temperature is normally displayed;

[0058] 4), open the stirring fan in the tempering furnace;

[0059] 5) When the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com