Annular liquid damper

A liquid damping and ring-shaped technology, which is applied in the direction of building components, building structures, and earthquake resistance, can solve the problems of RS-TLD system structure size coefficient increase, difficulty in meeting the optimal damping ratio, and difficult lifting and installation, etc., to achieve Huge economic and social benefits, simple structure, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0025] An annular liquid damper disclosed by the invention is mainly used for shock absorption of a towering steel chimney structure, and solves damage to the steel chimney structure caused by pulse vibrations generated by horizontal and vertical winds. Of course, in addition to being applied to high-rise steel chimneys, other main structures that require shock absorption can also be applied, and the present invention is not limited. The structure and working principle of the annular liquid damper of the present invention will be specifically introduced below by taking the application to steel chimney structures as an example. .

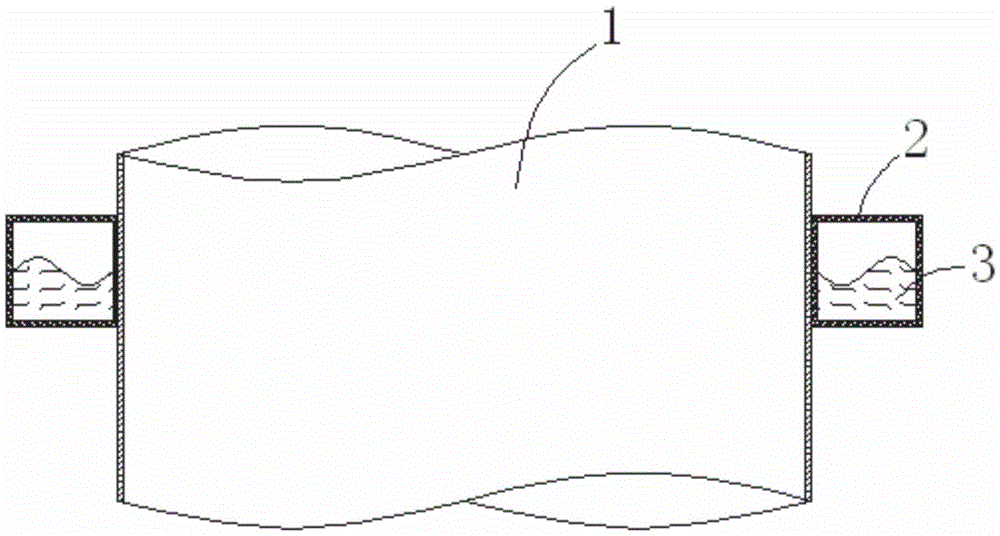

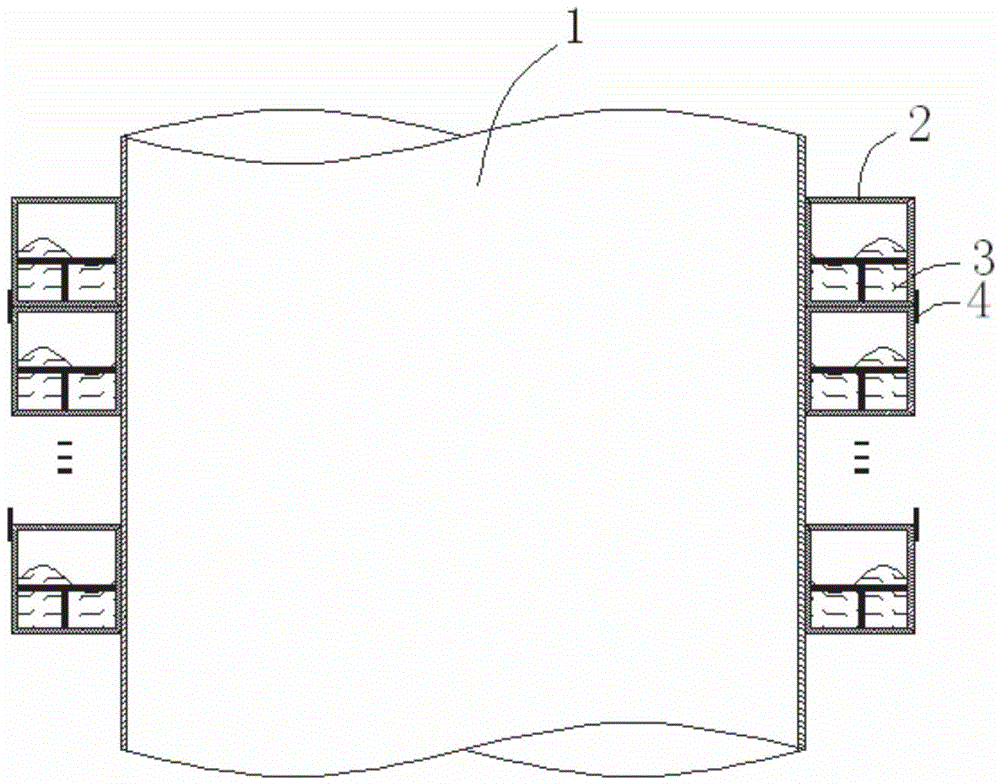

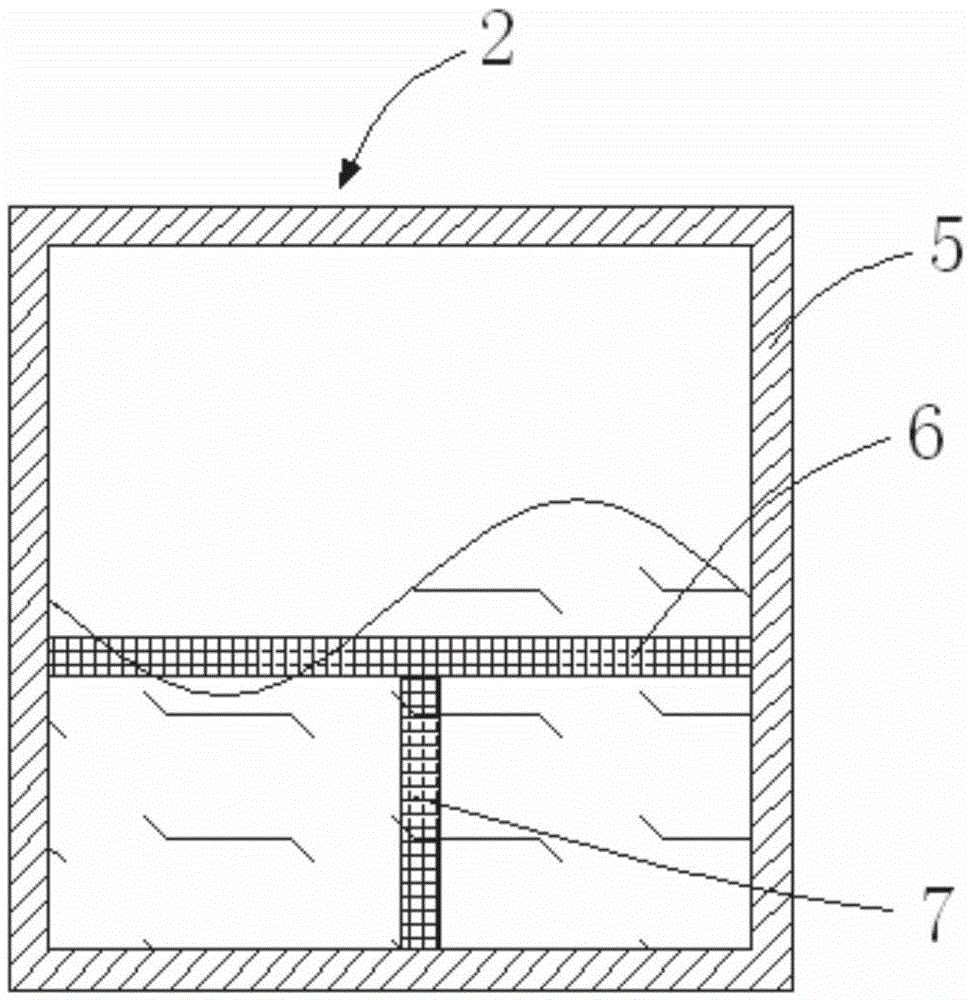

[0026] Such as figure 2 As shown, a kind of annular liquid damper disclosed by the present invention includes at least two layers of annular liquid damper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com