Rotary vibrating table and system

A technology of turntable and shaking table, applied in vibration testing, measuring devices, instruments, etc., can solve the problems of high minimum measurement frequency, low bearing capacity, and high price of shaking table, and achieve low minimum measurement frequency, high bearing capacity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

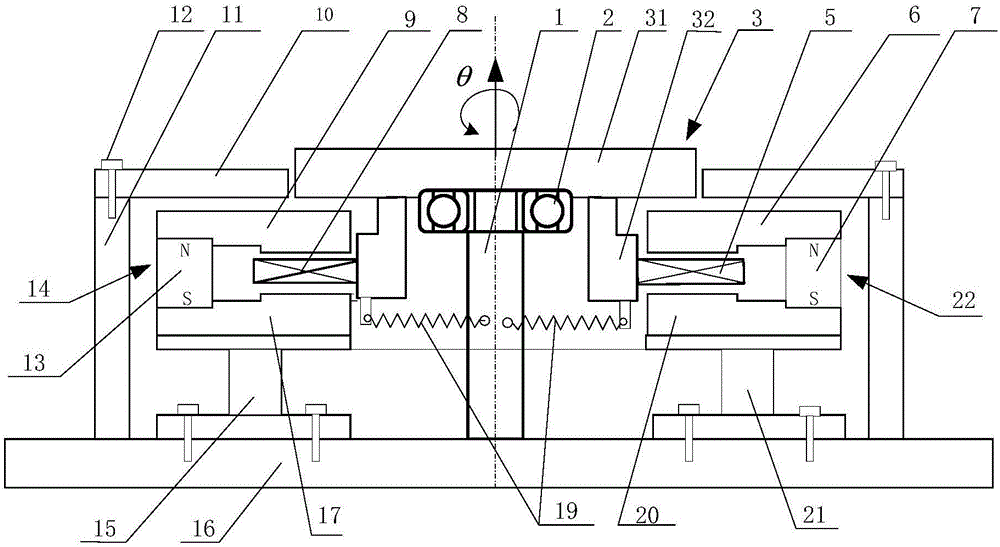

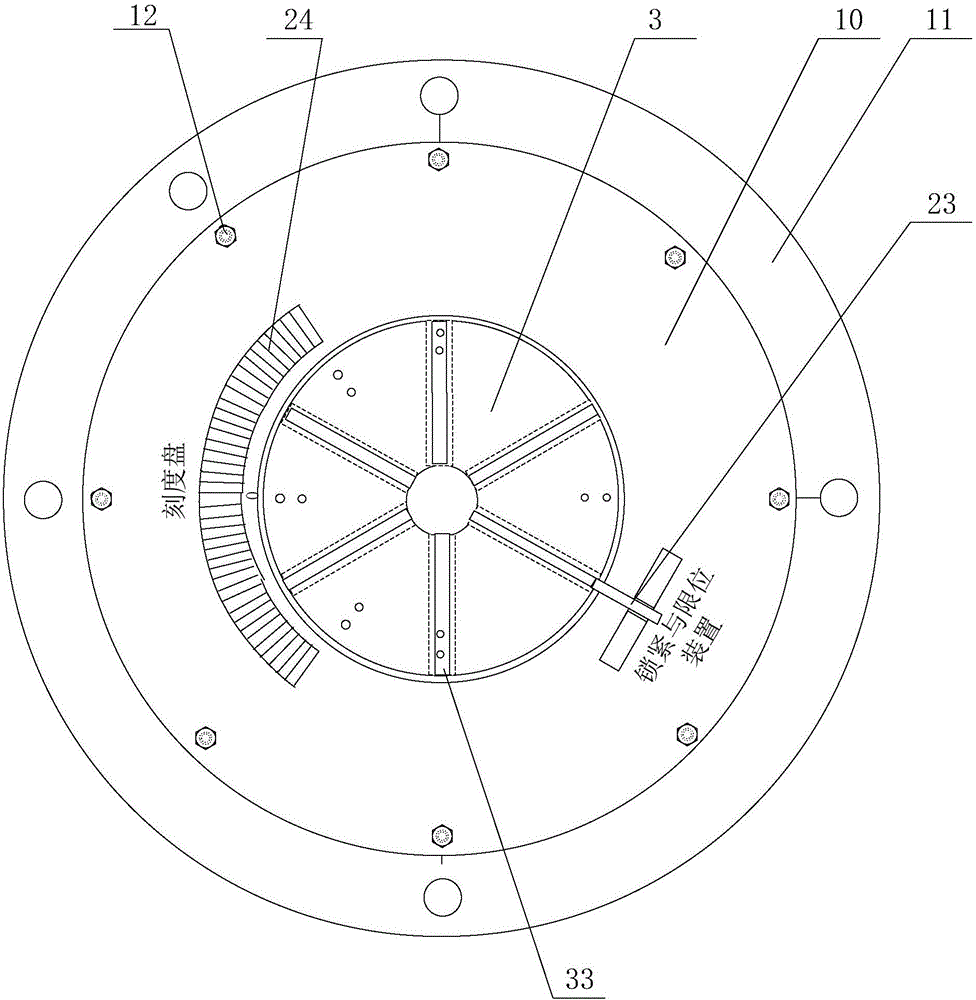

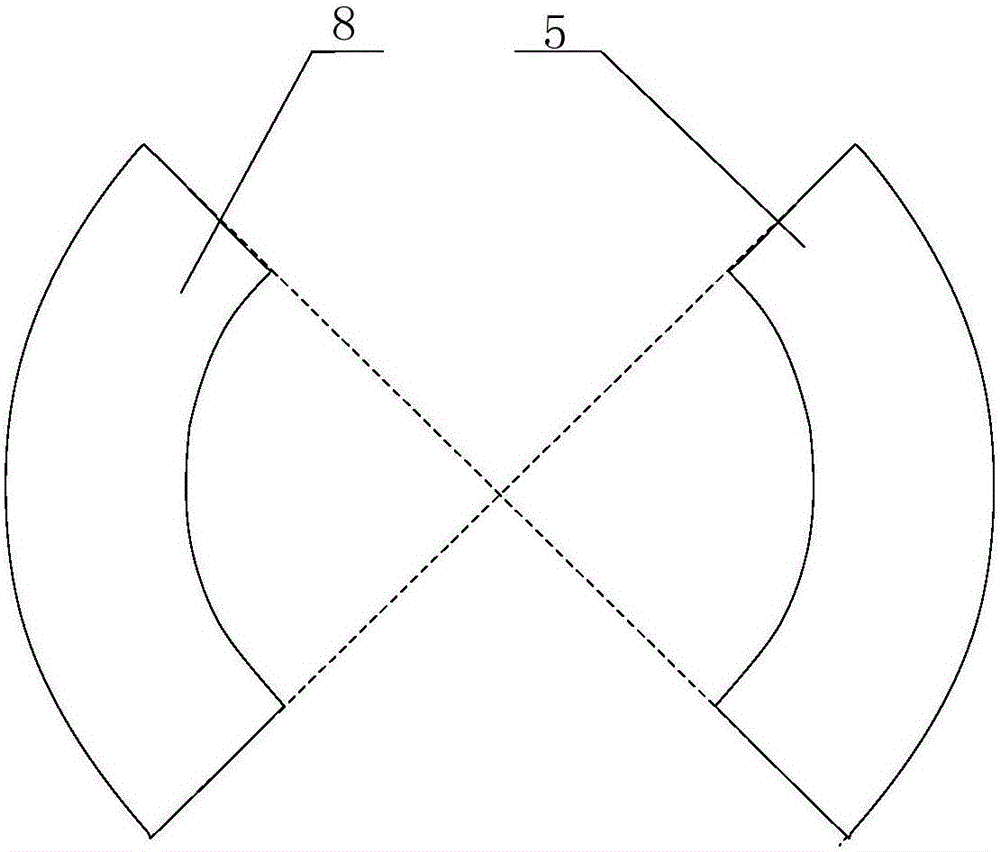

[0045]see Figure 1-Figure 8 As shown, the present embodiment provides a rotary vibrating table; figure 1 The first angle sectional view of the rotary vibrating table provided for this embodiment (the hatching is not shown in the figure); figure 2 Schematic diagram of the second angle structure of the rotary vibrating table provided in this embodiment; image 3 Schematic diagram of the structure of the drive coil and feedback coil of the rotary vibrating table provided in this embodiment; Figure 4 Schematic diagram of the structure of the driving permanent magnet and the feedback permanent magnet of the rotary vibrating table provided in this embodiment; Figure 5 Schematic diagram of the structure of the drive magnetic circuit and the feedback magnetic circuit of the rotary vibrating table provided in this embodiment; Figure 6 A cross-sectional view of the drive coil or feedback coil of the rotary vibrating table provided in this embodiment (only the label of the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com