High-temperature hydrochloric acid submerged pump

A submerged pump, hydrochloric acid technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of large maintenance workload and difficult long-term stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

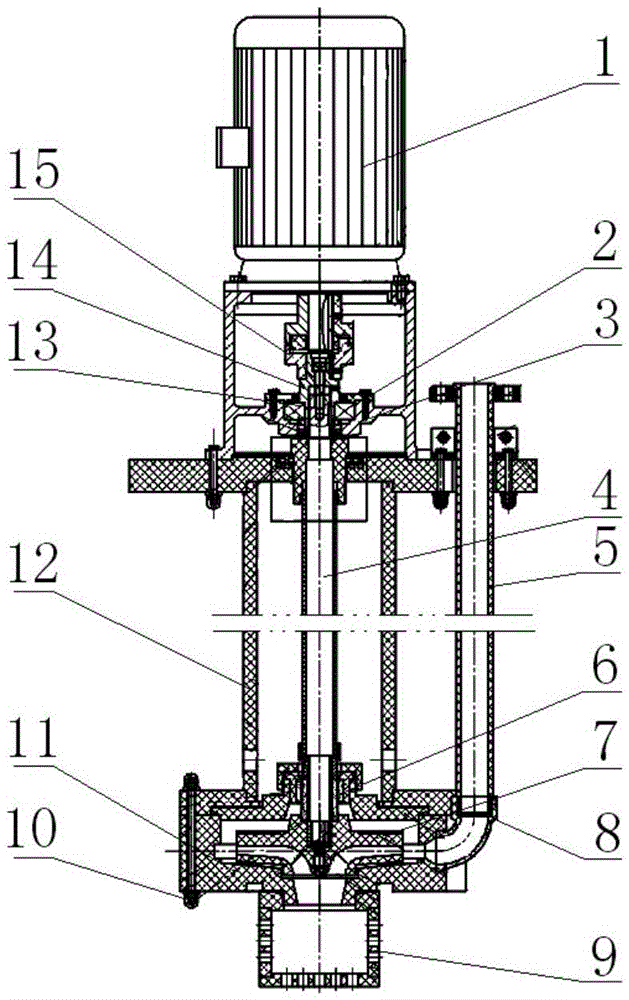

[0011] like figure 1 As shown, the high-temperature hydrochloric acid submerged pump includes a motor 1, a motor coupling 15, a pump coupling 14, a bearing housing shaft 13, a pump shaft 4, a support pipe assembly 12, an outlet pipe 5, a pump body 11, an impeller 7 and a leakage screen 9. The pump shaft 4 is located in the support tube assembly 12. The side of the support tube assembly 12 has an outlet pipe 5. The upper end of the pump shaft 4 is detachably connected to the bearing seat shaft 13. The upper end of the pump shaft is provided with a labyrinth seal. The pump shaft The lower end of 4 has impeller 7 and pump body 11, the upper part of pump shaft 4 has bearing seat 3 and rolling bearing 2, rolling bearing 2 is located in bearing seat 3, the lower part of pump shaft 4 is installed with sliding bearing 6, and the lower part of outlet pipe 5 has and support The elbow 8 connected by the pipe assembly 12 has a leakage net 9 under the pump body 11 . The submerged connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com