Tissue flail cutter brake system

A braking system and cutting knife technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of not being able to realize effective, fast, sensitive and accurate braking functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

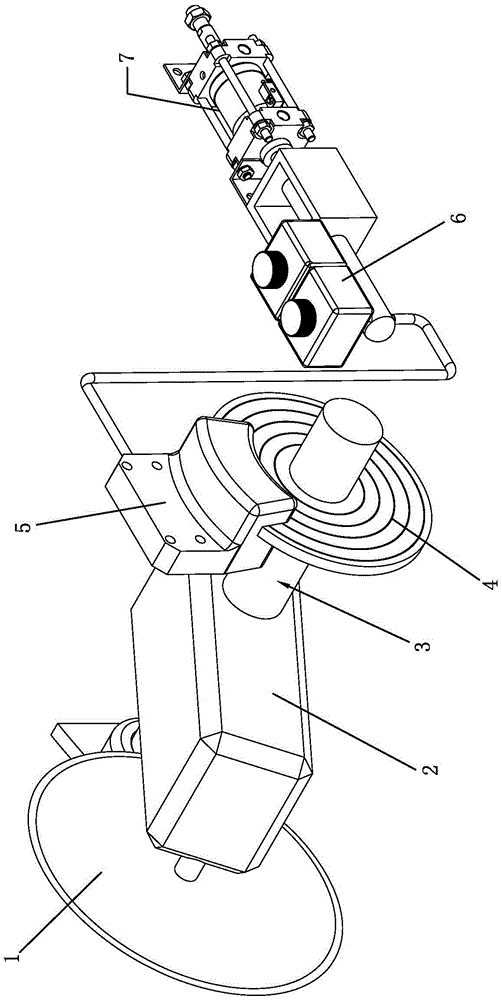

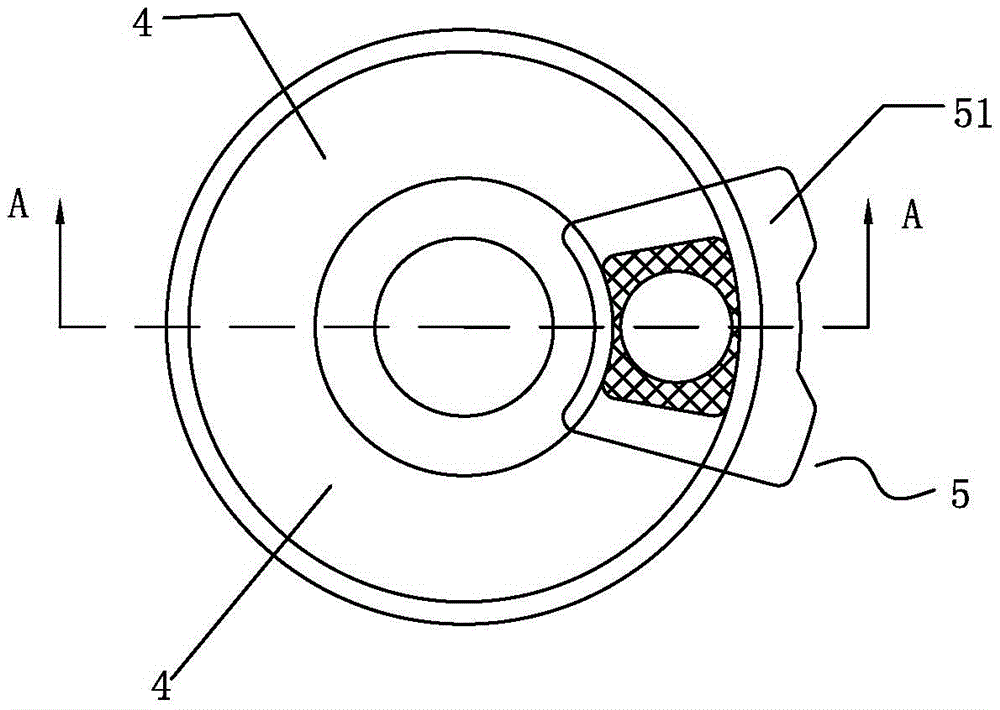

[0014] like figure 1 As shown, a paper towel throwing cutter brake system includes a throwing knife 1, a rotating knife rest 2 and a rotating shaft 3, and the rotating shaft 3 is fixedly connected to the knife rest 2; it also includes a brake disc 4, a braking mechanism 5, hydraulic cylinder 6 and cylinder 7,

[0015] The brake disc 4 is fixedly connected with the rotating shaft 3 , the brake mechanism 5 cooperates with the brake disc 4 , the hydraulic cylinder 6 is connected with the brake mechanism 5 , and the cylinder 7 drives the hydraulic cylinder 6 .

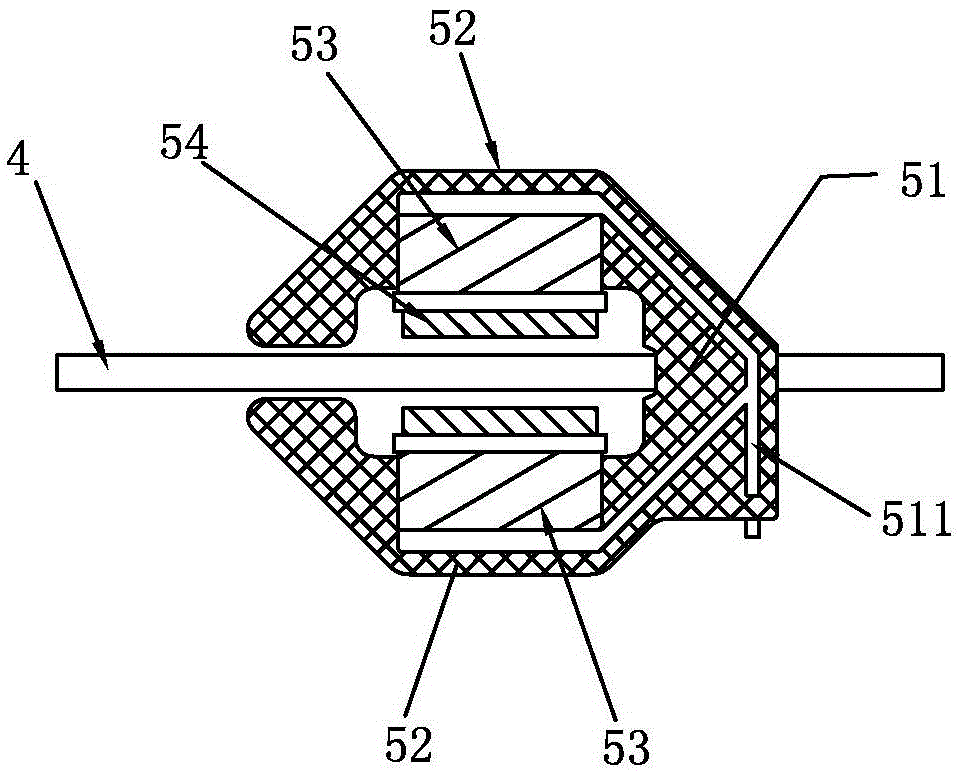

[0016] The brake mechanism 5 includes a base 51, two side body parts 52, a piston 53 and a friction plate 54, cylinder barrels are arranged on the opposite surfaces of the two side body parts 52, and the base 51 has a liquid inlet channel 511 for entering The liquid passage communicates with the cylinder and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com