Stirring and ventilating feed dryer

A dryer and feed technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of increasing air humidity and reducing drying efficiency, and achieve the goal of reducing noise and improving drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

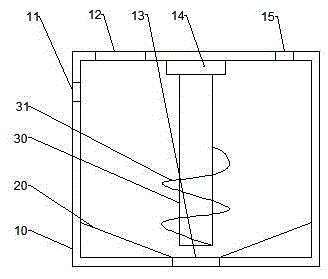

[0015] Such as figure 1 As shown, the agitated and ventilated feed dryer has a scheme as follows: including a body 10, the upper surface of the body 10 is provided with a feed inlet 12, the middle part of the bottom surface of the body 10 is provided with a discharge port 13, and the middle part of the inner upper surface of the body 10 is provided with a power supply. Device 14, the lower end of the power unit 14 is provided with a stirring rod 30, the stirring rod 30 is provided with a spiral stirring blade 31, the bottom surface of the body 10 is located at the discharge port 13 and symmetrically provided with inclined heating plates 20, and the side wall of the body 10 is provided with The air inlet 11 is connected with a fan, and the upper surface of the body 10 is provided with an air outlet 15 away from the air inlet 11 .

[0016] In addition, in this embodiment, a guide vane is provided on the air inlet 11 . The advantage is that the noise generated when the air flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com