Rubbing cloth used for manufacturing LCD, and manufacturing method thereof

A rubbing cloth and base cloth technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as splitting of single fibers, and achieve the effect of avoiding the confusion of rubbing orientations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

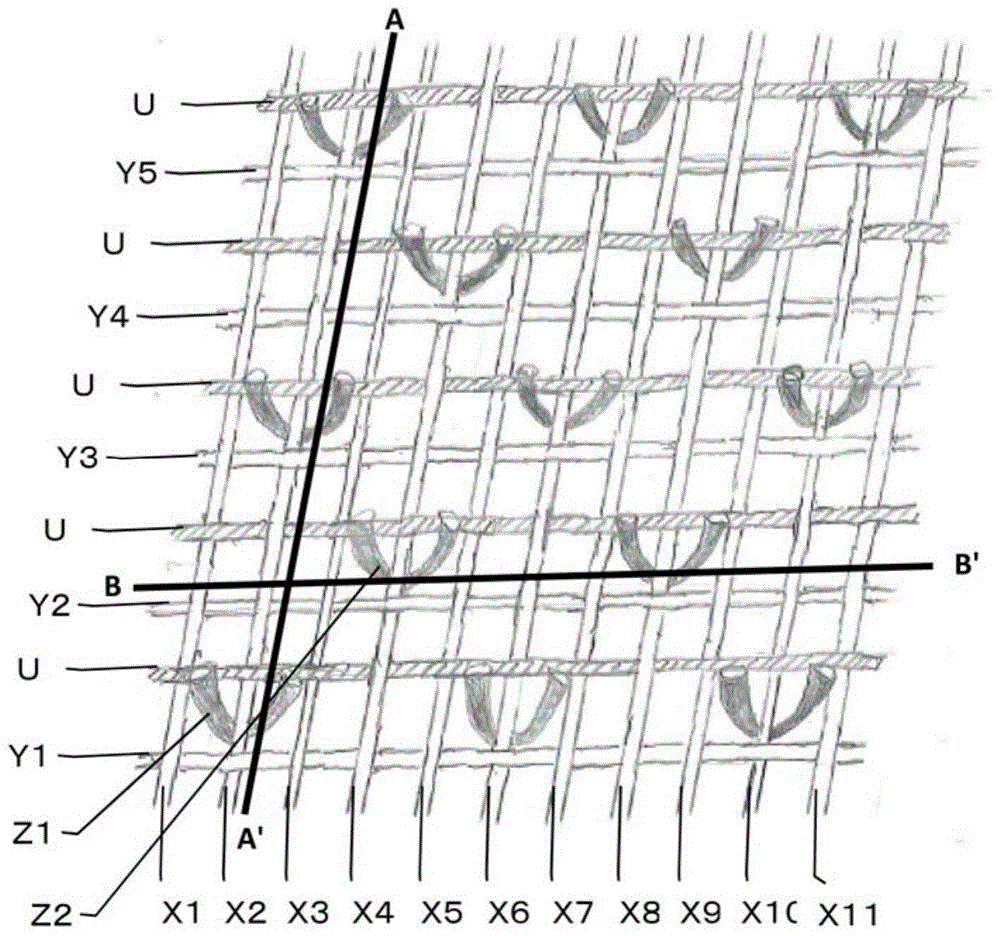

[0030] woven into figure 1 After the rubbing cloth for LCD is manufactured, it is cut by ultrasonic cutting machine TSC (manufactured by Takaoka Co., Ltd.) at cutting parts AA' and BB'. The frictional heat generated by high-speed vibration melts the cut surface to prevent cracking.

[0031] As a result of rubbing with a rubbing cloth for LCD manufacturing that can prevent the cutting part from fraying, it is possible to manufacture a high-quality LCD that avoids confusion in the rubbing direction caused by fraying, and does not cause a decrease in yield due to yarn dust. .

Embodiment 2

[0033] figure 1 After weaving the rubbing cloth for the manufacture of LCD with the same structure, it is cut by a press OPT-40H-110 (manufactured by Akebono Machinery Co., Ltd.) with a Thomson blade in the cutting section A-A' and BB'. In this case, the paint of the trade name "ピケ" (manufactured by Kawaguchi Co., Ltd.) was applied in a width of 10 mm from the cut surface. Nylon resin is added to "ピケ" to harden the cut surface and prevent it from falling apart. As a result of rubbing with a rubbing cloth for LCD manufacturing that can prevent the cutting part from fraying, it is possible to manufacture a high-quality LCD that avoids confusion in the rubbing direction caused by fraying, and does not cause a decrease in yield due to yarn dust. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com