Thermal power generating unit mechanical furnace coordination control method based on improved T-S fuzzy prediction modeling

A technology of fuzzy prediction and thermal power units, which is applied in the direction of adaptive control, general control system, control/regulation system, etc. It can solve problems such as failure to provide performance, unit operation deviates from design conditions, and large changes in the dynamic characteristics of furnace objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

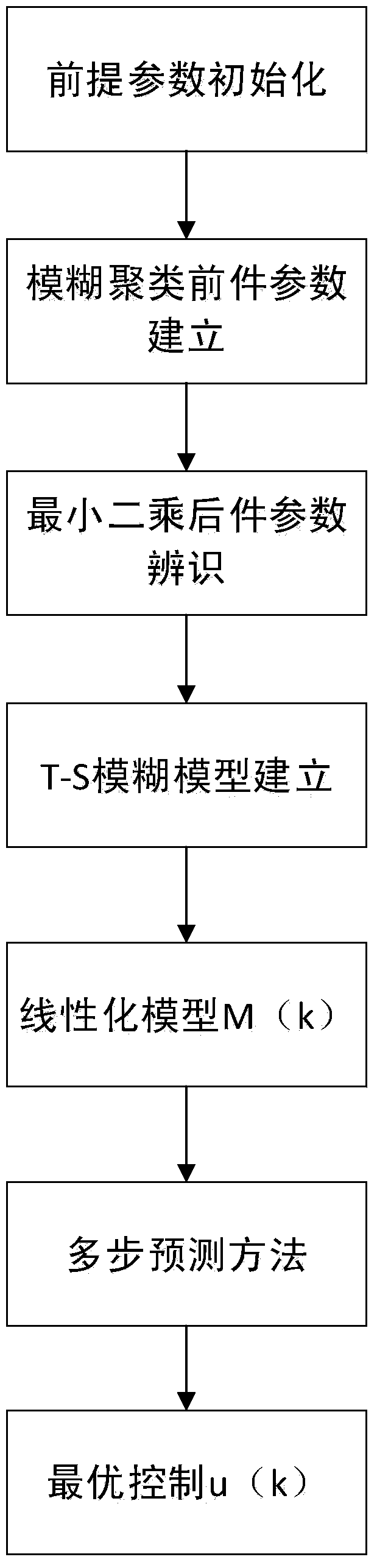

[0040] The invention discloses a thermal power unit boiler furnace coordination control method based on improved T-S fuzzy prediction modeling, such as figure 1 shown, including the following steps:

[0041] S1: Use the fuzzy clustering method to establish the optimal number of clusters;

[0042] S2: Identification of consequent parameters based on least square method T-S fuzzy model;

[0043] S3: Design a multi-step predictive controller.

[0044] Further, the step S1 includes the following steps:

[0045] S1.1: Given data set X={X 1 ,...,X N}, set the number of clusters c = 2 and the weight parameter m = 2, initialize the membership matrix U; where, X 1 ,...,X N Indicates the 1st data to the Nth data;

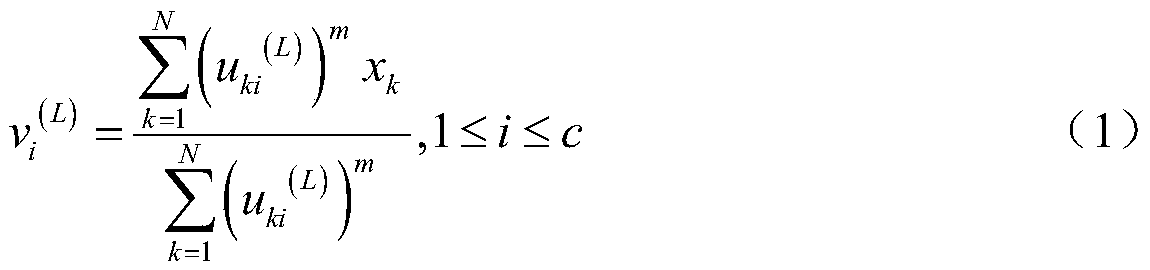

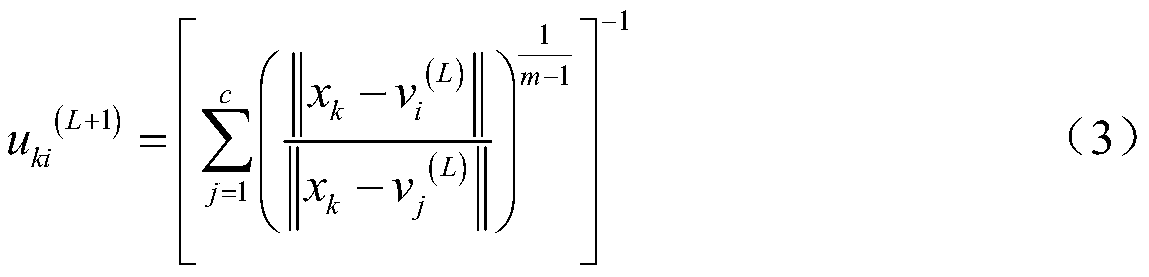

[0046] S1.2: When the number of iterations is L, calculate the center value of the i-th cluster:

[0047] v ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com