Control method for curing barn control system

A technology of control system and control method, applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., which can solve the problems of high energy consumption and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

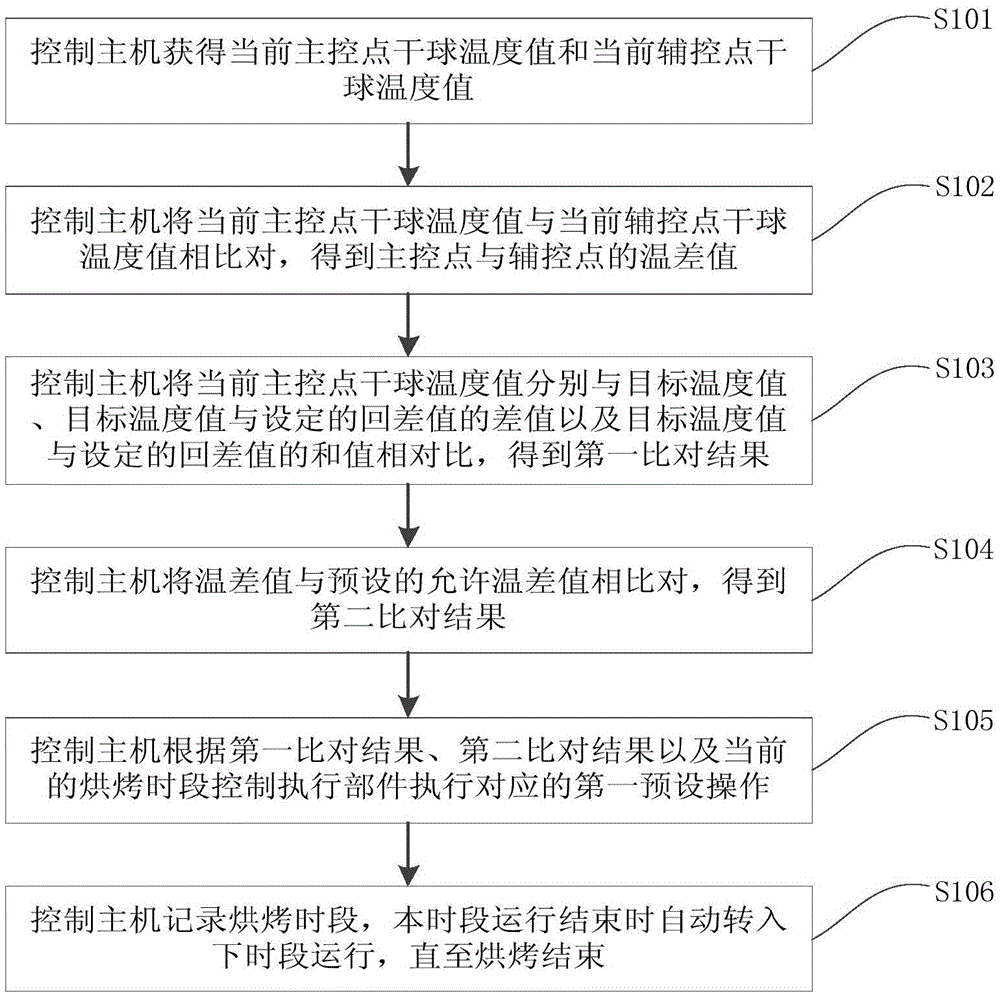

[0075] refer to figure 1 , an embodiment of the present invention provides a control method for a barn control system, the method is applied to an air source heat pump barn control system, and the air source heat pump barn control system includes a control host, a temperature sensor assembly, and an execution component. The temperature sensor assembly includes a main control point dry bulb temperature sensor and an auxiliary control point dry bulb temperature sensor, and the control host is connected to the main control point dry bulb temperature sensor, the auxiliary control point dry bulb temperature sensor and the executive The components are electrically connected.

[0076] The control method of the barn control system includes the following steps:

[0077] Step S101: The control host obtains the current dry-bulb temperature value of the main control point and the current dry-bulb temperature value of the auxiliary control point.

[0078] There are two dry bulb temperatu...

Embodiment 2

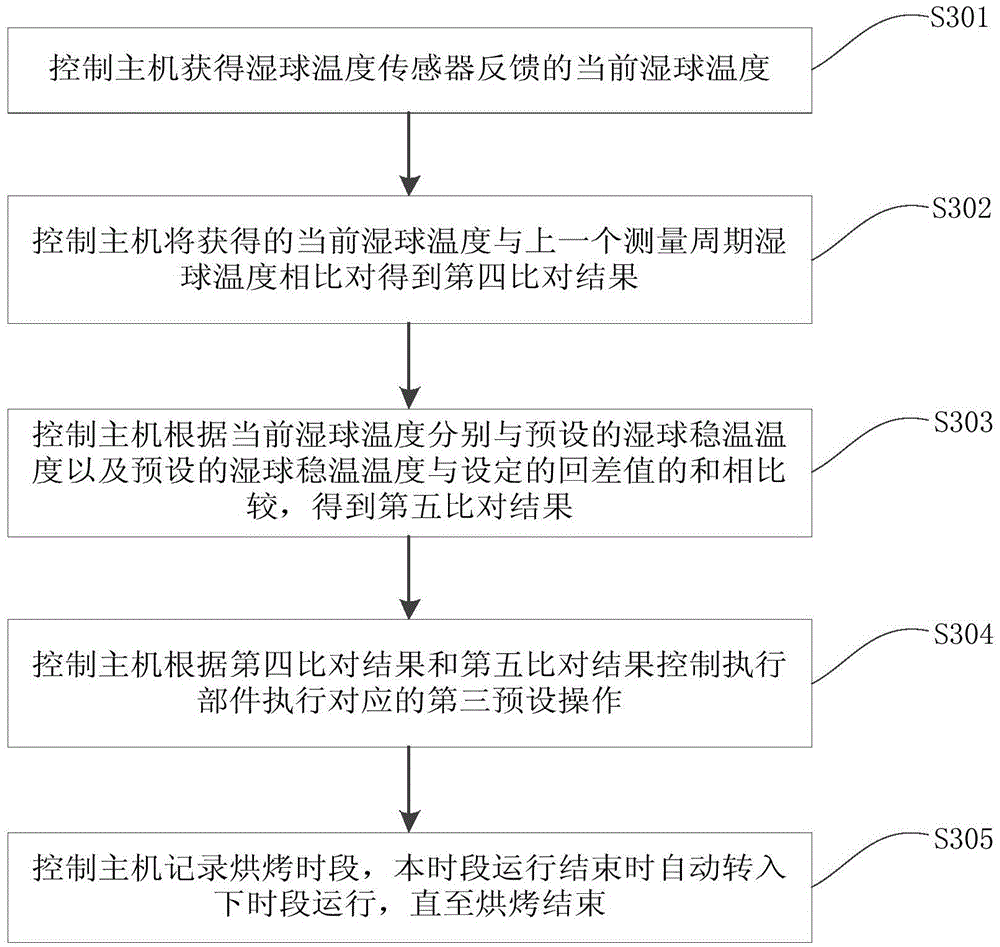

[0142] refer to image 3 , the present invention provides a control method of a barn control system, which is applied to the barn control system, the barn control system includes a control host, a temperature sensor assembly and an execution component, and the temperature sensor assembly includes a wet bulb temperature sensor , the control host is electrically connected to the temperature sensor assembly and the execution component respectively.

[0143] The control method of the barn control system includes the following steps:

[0144] Step S301: the control host obtains the current wet bulb temperature fed back by the wet bulb temperature sensor.

[0145] During the baking process controlled by the baking room control system, the wet bulb temperature sensor collects the temperature information in the drying room in real time to obtain the current wet bulb temperature, and feeds back the current wet bulb temperature to the control host, and sets the current wet bulb tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com