Laterally-mounted power-driven operation module

A technology of electric operation and driving parts, applied in the direction of protection switch operation/release mechanism, circuit, electrical components, etc., can solve the problems of low efficiency, increase production cost, and the depth of switch cabinet needs to be deepened, so as to reduce production cost and improve cost. Productivity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

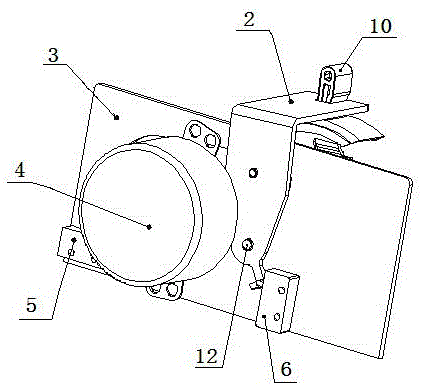

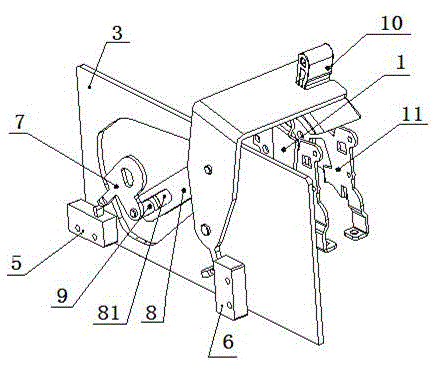

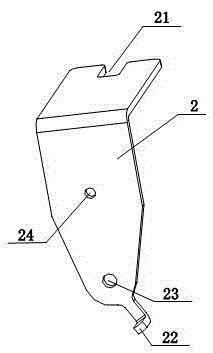

[0031] see Figure 1-2 As shown, the circuit breaker itself includes a handle 10, a bracket 11 and a rotating lever 1. The handle 10 protrudes upwards from the top of the circuit breaker. A bracket 11 and a rotating lever 1 are installed under the handle 10. The lower part of the bracket 11 is fixedly connected to the bottom of the circuit breaker. The bracket 11 supports the rotating lever 1, the handle 10 is fixedly connected with the rotating lever 1, and the handle 10 can rotate around the axis of the rotating lever 1 toward the wire-in end or the wire-out end of the circuit breaker. Such as figure 1 In the middle, the left side is the incoming wire end, and the right side is the outgoing wire end.

[0032] The present invention includes a side plate 3, a connecting rod transmission part, a motor 4, a handle driving part 2 and the like. The motor 4 rotates one circle in one direction. The motor 4 and the connecting rod transmission part are all located on the same side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com