Array substrate, manufacturing method thereof, and display device

A technology for array substrates and manufacturing methods, which is applied in the display field, can solve problems such as poor contact, the size of via holes cannot be too small, and the production yield of array substrates is reduced, so as to achieve the effects of improving production yield and opening ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

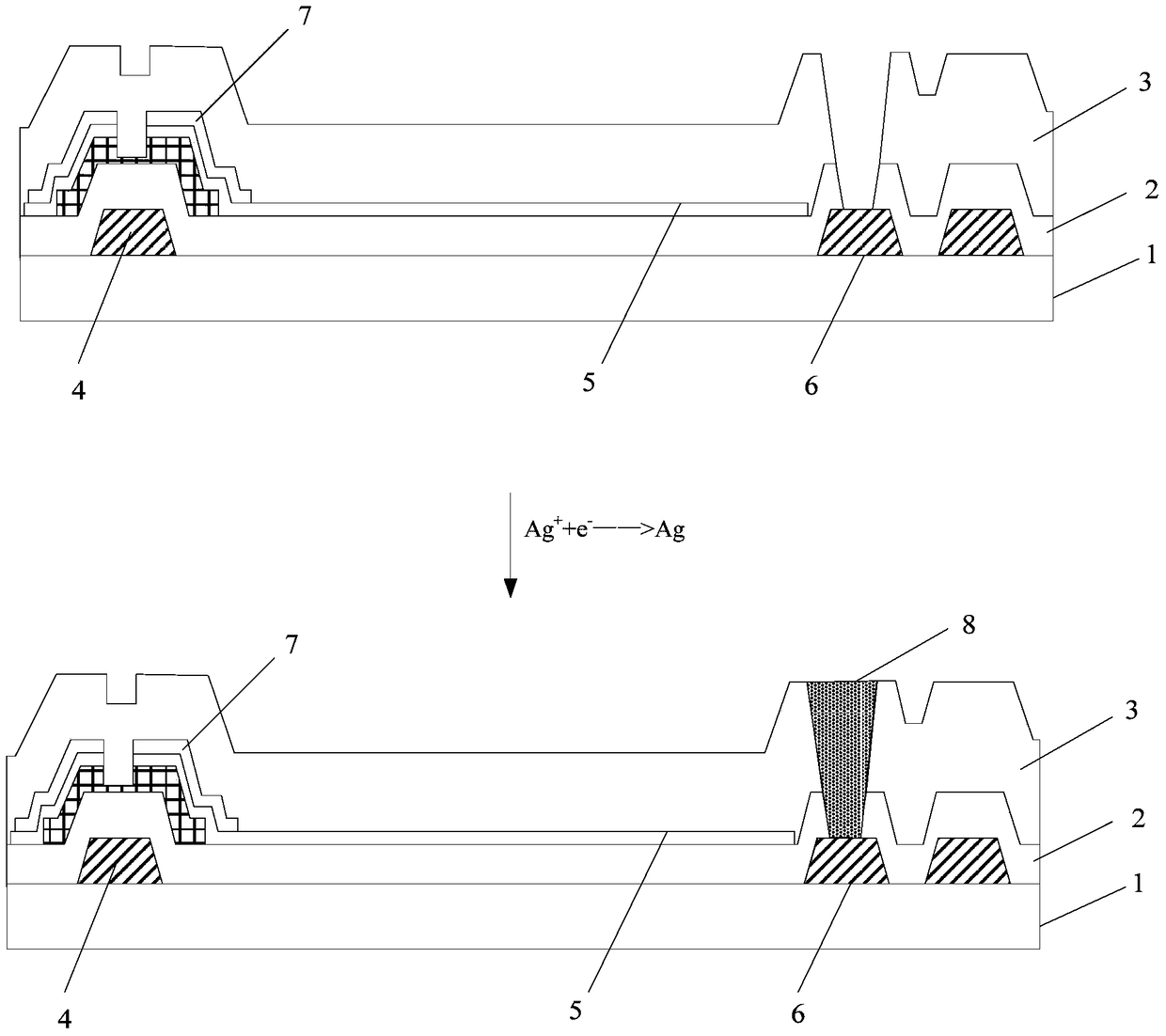

[0039] This embodiment provides a method for manufacturing an array substrate, including:

[0040] forming a first conductive pattern on the substrate;

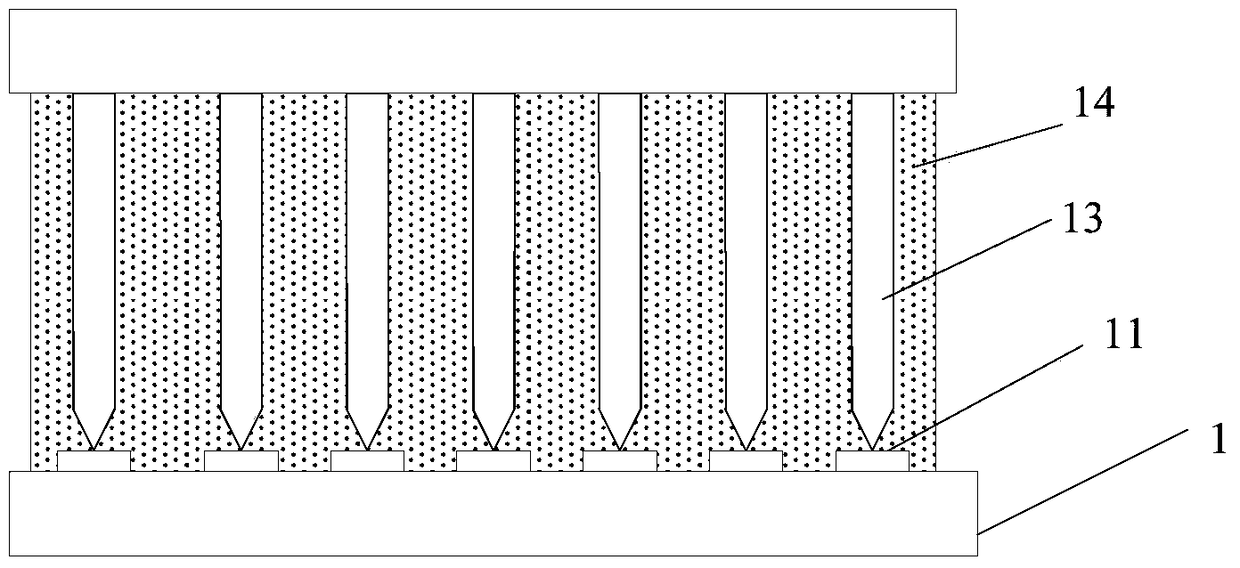

[0041] forming an insulating layer including a via hole on the substrate formed with the first conductive pattern, and at least part of the first conductive pattern is exposed at the via hole;

[0042] immersing the substrate formed with the insulating layer in a metal salt solution;

[0043] Input an electrical signal to the first conductive pattern, so that after the metal salt solution at the via hole contacts the first conductive pattern, the metal ions in the metal salt solution are reduced and deposited at the via hole to form a conductive connection department.

[0044] In this embodiment, the array substrate formed with the insulating layer is immersed in the metal salt solution, and an electric signal is input to the first conductive pattern exposed at the via hole of the insulating layer, and the metal salt soluti...

Embodiment 2

[0060] This embodiment provides an array substrate, which is manufactured by using the above manufacturing method, an insulating layer including a via hole is formed on the array substrate, and a conductive connection to the first conductive pattern is formed at the via hole department.

[0061]The technical solution of this embodiment does not have the problem of poor contact between the first conductive pattern and the conductive connection part, and can improve the production yield of the array substrate; and the technical solution of this embodiment does not require the size of the via hole, and can The conductive connection part is formed at the via hole, and the size of the via hole can be set relatively small, thereby increasing the aperture ratio of the array substrate.

Embodiment 3

[0063] This embodiment provides a display device, including the above-mentioned array substrate. The display device can be any product or component with display function such as LCD TV, liquid crystal display, digital photo frame, mobile phone, tablet computer, etc., wherein the display device also includes a flexible circuit board, a printed circuit board and a backplane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com